Zymark Turbo VAP 96

| Objektnummer | B00019653 |

|---|---|

| Seriennummer | 019653 |

| Object Naam | Zymark Turbo VAP 96 |

| Status | Gearchiveerd product |

Product groep: Rotatieverdampers / destilatie

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

Introduction

The Zymark TurboVap LV Evaporator is a microprocessor-controlled evaporator that provides simultaneous, automated concentration of multiple samples, unattended operation, convenience, and speed.

Automated

Microprocessor-control provides monitoring of the timed operation and water bath temperature. It also provides automatic gas shutoff and operational diagnostics.

Convenience

The operator is able to start a run of samples and leave it unattended. When the preset time has expired, the gas shuts Off automatically and the evaporator sounds a buzzer. The buzzer continues to beep every 30 seconds until operation is stopped.

Patented Technology

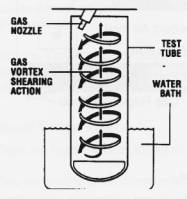

The patented "gas vortex shearing action" speeds evaporation.

Multiple Sample Processing

The evaporator uses one to five manifold rows. Each manifold has ten nozzles that extend into the tubes to supply the gas for evaporation. This allows up to 50 samples to be processed simultaneously. If you have less than 50 samples, you activate only those rows where samples are located.

Flexible

Evaporation may be paused, then stopped or resumed at any time. Time and temperature settings, and the selection of a row of tubes may be changed at any time.

Requires No Hood

The hinged cover and exhaust System save valuable hood space and permit benchtop use.

Complete With Accessories

Most of the hardware needed for installing and using the evaporator is provided. Racks and tubes are ordered separately. There are several rack sizes from which to choose. These include two types of 16 mm x 100 mm racks, two types of micro-centrifuge tube racks, two types of 15 mL conical bottom centrifuge tube racks, and racks for l0mm x 75 mm, 12 mm x 75 mm, 13 mm x 100 mm, 16 mm x 125 mm, 20 mm x 150 mm, and 10 mL conical bottom centrifuge tubes.

Specifications

Capacity: fifty tubes

Containers and Working Volumes: (using different racks)

Containers: Working Volumes

10 x 75 mm tubes up to 4 mL

12 x 75 mm tubes up to 4 mL

13 x 100 mm tubes up to 7 mL

16 x 100 mm tubes up to 12 mL

16 x 125 mm tubes up to 16 mL

20 x 150 mm tubes up to 30 mL

10 mL conical bottom tubes up to 10 mL

15 mL conical bottom tubes

up to 15 mL

15 mL volumetric

conical bottom tubes,

up to 15 mL

(compatible with the AutoTrace SPE Workstation)

1.5 - 2.0 mL micro-centrifuge tubes

(screw cap type)

1.5 to 2 mL

1.5 - 2.0 mL micro-centrifuge tubes

(flip cap type) 1.5 to 2 mL

NOTE: Full sample tubes must be evaporated with care to prevent splashing.

Typical Evaporation:

Rates: Solvent Time (min.)

Ethyl Acetate 17.5

Hexane 9

Methanol 25.5

Methylene Chloride 17

* Conditions:

10 mL of solvent evaporated to dryness at 52 °C. Methylene chloride bath temperature at 38°C.

Gas Consumption:

1 cfm per row of nozzles at 15 psi (from a source capable of supplying 60 to 100 psi.)

Water Bath Temperature Range:

ambient to 90°C

Gas Regulator and Gauge Range:

0 to 30 psi (206.9 KPa)

Dimensions:

Height: 11.9" (30.2 cm)

Width: 21.2" (53.8 cm)

Depth: 11.9" (30.2 cm)

Weight :

40.5 lbs. (18.47 Kg.) empty water bath

Time Range:

1 to 99 min. or 0.1 to 9.9 hrs. can also be set to 00 for infinite time

*** NOT for in vitro testing ***

Theory of Operation - Helical Gas Flow

The evaporator takes advantage of a patented gas vortex shearing action that maintains high evaporation rates regardless of sample height in the tubes. The helical flow sets up a vortexing action that provides for sample homogeneity and continuous rinsing of the tube wall. The vapor-laden gas exits via an unobstructed path up the center portion of the tubes and is removed by an exhaust fan to the exhaust port in the back of the unit. From the exhaust port, the exhaust duct is routed by you to a suitable, outside-vent location.

Main Features

Cover

Operation automatically begins or resumes when the cover is closed. The evaporation pauses when the water bath cover is open. After an evaporation, open the cover to prevent condensation within the unit.

Control Panel

The control panel allows you to control evaporation in one to five rows of 10 tube positions. (Samples are not required in each position.) The microprocessor constantly monitors the control panel allowing you to make changes to the panel settings at any time during the evaporation process. Yellow lights indicate the row(s) of tubes selected. The green light to the right of the START/PAUSE button is on when an evaporation is in progress and blinks when the evaporation has been paused. A STOP button on the control panel allows for termination of the evaporation process. The control panel also has two displays: one indicates time remaining; the other indicates the actual water bath temperature. These displays also provide diagnostic codes when an error is detected.

Automatic Control

The Operator sets the desired evaporation parameters for each run. After pressing the START button and closing the lid, the evaporator automatically monitors the programmed process. A buzzer sounds when the evaporation is completed.

Water Bath

Sample tubes are placed in a rack that sits in a temperature-controlled water bath. The water bath operates over a temperature range of ambient to 900C.

The TurboVap LV evaporator is not designed to cool but the water bath temperature can be brought down as much as 15C0 by using the evaporation as a cooling source. Cooling ability varies with the evaporation rate.

Use the numeric pushwheel to select the desired temperature setting.

Gas Supply

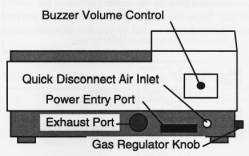

The evaporator has a gas supply input on the back of the unit. The fitting provided has an internal shutoff which allows you to disconnect the evaporator from the supply without shutting off the gas supply itself.

There is a gas regulator knob on the side of the unit and a gauge on the front panel. Use the gas regulator knob to reduce the external gas supply pressure (60 psi to 100 psi) to the 0 to 30 psi desired helical gas flow directed at each of the sample tubes.

The gas supply is routed through a stainless steel manifold to each sample tube.

Exhaust Port

Solvent vapors are removed by an exhaust fan and routed to the exhaust port on the back of the unit. You must route the venting hose from the exhaust port to a proper ventilation System venting to the outside. The TurboVap LV" s design assures that vapors are contained for you to remove from the laboratory environment.

Once the TurboVap LV is properly installed and properly vented, vapors remain contained and they are removed automatically when the system is operating properly.

Buzzer Volume Control

There is a buzzer with an adjustable volume control in the back of the unit.

Turn the knob in either direction until the desired volume is achieved.

A repeating beep indicates a completed run.

A long beep indicates interrupted operation.

A short beep indicates a recognized key input.