Waters HPLC 3

| Objektnummer | B00011107 |

|---|---|

| Seriennummer | 011107 |

| Object Naam | Waters HPLC 3 |

| Status | Stock unit |

Product groep: HPLC systemen

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Firma: Waters

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representating the delivery volume. The exact delivery content you will find only in the offering text.

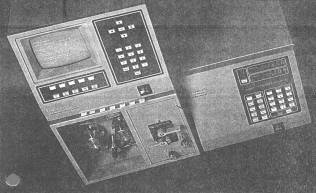

Controller 600E

The new Waters 600E Gradient Module.

An elegant approach to low pressure mixing.

Until now, the design of low pressure gradient systems had to be based on compromise. To maintain the simplicity of a true single pump configuration, manufacturers had to accept a trade-off in performance-blending accuracy and precision varied with changes in system back pressure and flow rate. To compensate, some relied an additional mechanical complexity. But the extra pumps and plumbing tended to obscure the original benefits of the low pressure concept: reliability, convenience and cost.

The new Waters 600E Gradient Module is the first low pressure mixing system to overcome the problems of earlier generations of the technology. It offers no-compromise high performance and true single pump design. This has been achieved by combining two Waters potented technologies: time-proven solvent delivery and innovative RPS software. The result is capability unmatched by any other single pump system.

Engineered for the real world.

Compact, stackable. The Waters 600E takes up less than 12" of voluable bench space, and stands solid, for stocking additional components.

Slide-out column compartment protects columns and fittings. A handy drawer protects your columns and glides out easily, giving you ready access to all fluid connections.

Built-in temperature control. The column drawer accommodates a heating chamber, programmable via the keypad, for separations requiring elevated column temperatures or for improved reproducibility in labs where ambient temperature fluctuates greatly. Only Waters gives you a choice of temperature control for stainless steel columns or Radial-Pak- cartridges.

Readily accessible pumping components. Serviceable design make it easy for you to perform routine maintenance.

Built-in HELP key. Information on all parameters is available at any time.

Performance Specifications

Pump Performance

Flow range: 0.01 to 45.00 ml/min or 0.01 to 20 ml/min, with no plumbing changes (0.01 ml/min increments)

Compositional range: 0 to 100% in 1 % increments

Compositional ±0.15% for flow rates of 0.01 to 10.00 ml/min, independent of reproducibility: system back pressure

Compositional accuracy: ±0.5% for flow rates of 0.01 to 10.00 ml/min, independent of system back pressure

Flow rate precision: ±0.1%. for flow rates of 0.01 to 10.00 ml/min

Pressure maxima: 6000 psi for flow rates of 0.01 to 10.00 ml/min; 1000 psi at 45.00 ml/min

Programming Features

Gradient profiles: Up to 225 linear and/or non-linear segments can be linked; up to 15 segments per method

Programmable timed Control of accessories via four powered switches

events: Changes in helium sparge rate

Change to new method

Audible alarm

Changes in temperature of column heater

Video monitor: Display of complete gradient and timed-event methods; prompting cursor; real-time display of critical operating parameters

Program storage: E 2 PROM (Electronically Erasable Programmable Read Only Memory) provide permanent storage of up to 15 multi-step gradient and 15 multi-step timed event methods

Environmental 4°C-38°C; 20%-90% relative humidity (non-condensing)

operating temperature:

Operational Specifications

Automatic Solvent Sparging Standard, helium gas, input gas pressure range 50 to 150 psi (3.5 to 10.5 kg/cm 2 ). Helium flow rate range 0 to 100 ml/min, programmable to 1ml/min.

Pressure Maxima 6000 psi (420 kg/cm 2 ) at 10ml/min.

1000 psi (70kg/cm 2 ) at 45 ml/min.

Programmable Pressure Limits Upper 51 to 6000psi (3.5 to 420 kg/cm 2 )

Lower 0 to 5950 psi (0 to 415.5 kg/cm 2 )

Program Storage Storage for sets of 15 tables (gradient, program event and detector), with a maximum of 15 steps per table.

Storage for a time-based multi-method program with up to 48 individual steps.

EEPROM stores setup parameters and tables and preserves memory indefinitely following power loss or extended shutdown.

Gradient Profiles Eleven gradient curves (including linear, Step [2], concave [4] and convex [4]. Up to 80 curve segments can be linked.

CRT Display 5 (12.7cm) diagonal screen. Sixteen lines with 40 characters per line. Displays current operating conditions. Allows operator to monitor complete gradient and timed event tables on single screens. Reverse video cursor prompts operator through program setup.

Keyboard Dedicated keys provide direct access to all display screens. Cursor movement keys simplify programming, editing and parameter entering. All keys are solvent resistant.

Programmable Timed Eighteen (15) timed events can be programmed and

Events stored for each table. They are:

· Set S1-S4 for accessory control

· Audible alarm

· Set sparge rate

· Set column temperature

· Return to initial conditions

· Change to new gradient table

Electrical Specifications

Chart Output Two terminals (+, -) for recording pump pressure traces when performing service procedures or monitoring solvent changes (analog bypasses microprocessor). 10mV output.

Ground Terminals Connected to signal ground used as reference for outputs (HOLD, INJect and switches S1 to S4), inputs (Inject and Abort), or 12 V power supply (not for use with 10 mV outputs).

DAD 991

Product description

The Waters 990/991 Series Photodiode Array Detector (the PDA) is an ultraviolet/visible (UV/VIS) detector and advanced data System for use in high performance liquid chromatography.

The photodiode array simultaneously measures absorbance values from 190 to 800 nanometers (nm).

The PDA can assist peptide researchers in assessing peak purity and locating peaks with side chain modifications, aromatic residues, or other unusual characteristics. Molecular biologists can use the PDA to readily identify DNA peaks based an their UV spectra collected during separation. The PDA can enable pharmaceutical researchers to easily find structurally similar metabolites.

PDA Features

Features of the PDA include:

Dual-tasking feature that allows synchronous data collection, processing, and reporting

Post-run batch processing and reporting

Report scheduling

Wavelength range from 190 to 800 nanometers (nm)

Collection of three-dimensional or two-dimensional data

Detection of components absorbing UV/VIS light

Peak integration and quantitation

Display and reporting of three-dimensional, two-dimensional (chromatogram), and spectral data.

Wavelength and spectral data storage

Identification of unknowns by comparison to known spectra stored in the PDA spectral library

Peak purity determination

Specifications

Resolution: 1.3 nm

Number of diodes: 512

WcNelength range: 190 to 800 nm

Wcvelength accuracy: ± 1.0 nm

Flow Cell; 8.0 µI, 10.0 mm path length

Linear range: -0.1 to 1.6 AU

Noise: < ±2.5 x 10-5 AU at 254 nrn

Drift= <1 x 10-3 AU/hr at 254 nm

Analog gutpur lhrom NEC) One channel

1 V/FS or 10 mV/FS

Fast or slow response

Analog Input: Four channels

AC povver: 110 V, 120 V, 220 V, 240 V

Lamp: Deuterium

Input/Output (NEC): TTL Trigger In, Trigger Out

High or Low Active

Dimensions (detector): Width: 28.5 cm (11.2 in)

Height: 23.7 cm (9.3 in)

Length: 54.0 cm (21 .5 in)

Weight 25 kg (55 lbs)

Sample Processor 715 Ultra WISP

The Waters 715 Ultra WISPTM Sample Processor, referred to as the Ultra WISP, is a versatile, easy-to-use sample processor module that fully automates the injection process for high performance liquid chromatography (HPLC) instruinentation. The Ultra WISP may be programmed to inject up to 96 sample aliquots in either sequential or random fashion. Injection volumes are programmable from 0.1 to 2000 microliters (ul).

The Ultra WISP provides the following features:

Microprocessor-based all electric design

CRT with programming keypads

Patented dual port restrictor loop injector design

Sequential or random vial operating program

IEEE and RS-232 communications

Integrated needle wash system

Three syringe options

Two sample loop sizes

Two carousel sizes

In addition to programming a normal auto run, the Ultra WISP program enables you to:

Interrupt and then resume a normal run to perform a stat run

Run standards separately from the method table to simplify programming

Perform auto addition, co-injecting the contents of a common vial with the samples

Perform auto transfers to withdraw up to three reagents to transfer to samples

Program external event outputs

Suspend a run to reprogram sample parameters or to add sample vials to the carousel

Program the needle to withdraw sample from different levels in the vial

Purge the system and perform compression and bubble checks

The Ultra WISP is compatible with the Waters PowerLineTM family of HPLC systems and can also be programmed from a Waters 600E System Controller.

Maintenance of the Ultra WISP is simple due to the modular design of the flow path. The Ultra WISP is self-diagnosing, displaying system and error inessages when appropriate. For further diagnosis, you may also manually operate the individual assemblies.

General The Ultra WISP can routinely operate with system backpressure up to 4500 psi.

Any LC solvents compatible with current pump and column technology can be used with the Ultra WISP. Salts and buffers can reduce seal life, especially at system backpressures in excess of 3000 psi, and in absence of needlewash and regular maintenance and cleaning.

Physical Requirements Electrical Power - Nominal input voltage 100, 120, 220, 240 at 48-52, 58-62 Hz

Voltage may vary by +10% of nominal; a variation of - 10% longer than 13 milliseconds is considered a power loss.

Sample Capacity 48 Vial Carriage - 48 - 4 ml or optional 250-µl Low Volume Insert (LVI) screw cap vials per carriage; Teflon self- sealing or Teflon disc septa.

96 Vial Carriage - 96 - 1 ml snap-in push cap or optional 150-µl LVI vials per carriage.

Sample Volume 48 Vial Carriage - 2.0 ml maximum injectable volume (from 4 ml total); liinited volume inserts (LVI) allow minimum sample waste volume of 6 µl (maximum injectable volume - 244 µl).

96 Vial Carriage - 1 ml maximum injectable volume. Minimum sample required - 300 µl. Limited volume inserts (LVI) allow maximum injection volume of 120 µl.

Minimum Sample Volume 0.1 microliters

Functions Replicate injections as programmed from the controller

Output signals to reset gradient, start integrator, flow detector

Purge flow path with mobile phase

Discrete needlewash to prevent cross contamination

Programmable standard sequencing

Carry Over Less than 0.1% previous sample component concentration; except through sample interaction with 304 stainless steel parts.

Cross Contamination Dependent on selection of needlewash solvent and sample interaction with 304 stainless steel parts.

Injection Volume Delivery Mobile phase (degassed) tested at 100 psi, with Teflon disc vial septa, auxiliary sample loop out and preset operational parameters.

Mobile Phase Actual Volume (%)* at:

5µl 10µl 50µl

3% acetone in MeOH 95 98 99

Napthalene in CH2C12 75 85 95

3% acetone in H20 99 99 99

*Shown as a percent of programmed injection volume.

Theoretical results - actual is solvent dependent.

Reduced delivery will be observed for MeOH and CH 2 Cl 2 with higher solvent compressibility self-sealing septa and auxiliary sample loop.

Most accurate injection volume (all solvents): 50 µl.

Reproducibility Less than or equal to 1 % for 1 to 100 µl injections.

Linearity Coefficient of determination of greater than .99 for a range of 0-100µl.

Ultra WISP Part number 044500

Dimension Height: 17 inches (43.2 cm)

Length: 24 inches (61.0 cm)

Width: 15.25 inches (38.7 cm)

Weight 94 pounds (43 kg)

Desired Site conditions Humidity of 20 - 30%

Temperature of 16 to 27°C (60 - 80° F)

Dust level relatively low

Requires bench space of approximately 29 x 15.25 inches (74 x 39 cm).

Frequency The nominal frequencies of the Ultra WISP are 50 or 60 Hz; the operable frequency range is the same for both of these frequencies: 47 - 63 Hz.

Voltage Requirements Nominal Line Operable Voltage

Voltage Range

100 85-130

120 85-130

220 185-265

120 185-265

Fuse Requirements Nominal Line Fuse Fuse

Voltage Required Size

100 one 3-amp 0.25x1.25 inches (6x32mm)

120 one 3-amp 0.25x1.25 inches (6x32mm)

220 two 1.5-amp 5x20mm (0.20x0.78 inches)

240 two 1.5-amp 5x20mm (0.20x0.78 inches)

Communications Connectors IEEE-488: For connection to compatible Waters Data and Control Stations such as the 600E System Controller.

RS-232: For injection parameter transfer to a data module, such as the Waters 745.

Temperature Control: For future use with temperature control components.

Input Terminals The specifications for the Hold terminals are as follows:

TTL or switch closure compatible

Low trigger of 1.8 volts

High trigger of 3.0 volts

Protected to ± 30 volts

Minimum of 30 millisecond pulse

Maximum of 5 milliamps current

Output Terminals The specifications for the Inject Start, Run Stop, and Out terminals are as follows:

Contact closure compatible

Maximum 10 watts with the following restrictions: maximum of 0.5 amps current (to 20 V), maximum 130 VAC (to 0.07 amps)

Maxima 820