Waters 616

| Objektnummer | B00012826 |

|---|---|

| Seriennummer | 012826 |

| Object Naam | Waters 616 |

| Status | Gearchiveerd product |

Product groep: HPLC pompen (gradiënt)

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Firma: Waters

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

The Waters 616LC system is a High-Performance Liquid Chromatopraphy (HPLC) pumping system for microbe, narrow-bore, and analytical chromatography and micropurifications.

Uses 0.005 and 0.009 inch I.D. stainless steel tubing to optimize system performance.

Performs complex methods with less eluent and in less time than semi-preparative systems.

Features

- 50 µl pump head volume

- Maximum system pressure: Pump 616: 6000 psi (420kg/cm 2 )

- 0.01 to 5.0 mL/min operating flow rate

- Four-eluent gradient capability (Auto Blend method)

- Automatic eluent degassing by helium sparge

- Pump vent valve to facilitate priming and purging of eluent lines and changing eluents

- Rheodyne 7725

- Automated, continuous plunger seal wash with integral pumping system

- Single keypad control with PowerLine system controller

- Methods storage allowing access to previously creafed gradient, event, autosampler, and

detector programs

- 11 preprogrommed gradient profiles including:

-- Step change at Start of segment

-- Step change at end of segment

-- Linear change

-- Four convex gradient curves

-- Four concave gradient curves

- System control of PowerLine detectors and autoinjectors through IEEE-488 interface

- RS-232 serial communications interface for connection to optional Integrator

- Optional shelf unit to hause system modules.

- SILK pumping technology for pulse-free flow

- Optional column heater monitoring

- Low-dispersion system volume for rapid eluent changeovers and norrow-bore/microbore

Separations

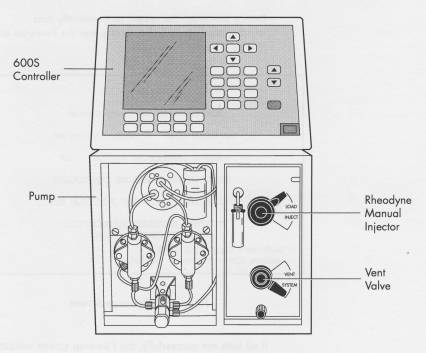

Waters 600S Controler

Controls eluent gradient, flow rate, external events, and sparging for the Waters 616 LC system.

Provides connection terminals and communication ports for Operation with and control of external devices, such as detectors, autosamplers, and data Systems.

Waters 616 Pump

Contains components required to blend and to deliver eluents from the eluent reservoir bottles to the injector and column.

Consists of the pump with 50-µL volume pump heads, plunger wash pump, eluent sporge volve assembly, eluent proportioning valve assembly, manual injector, and vent valve.

Rheodyne 7725i Injector (optional)

Contains one 20-µL sample loop. The 616 LC system Startup Kit includes 5-µL and 200-µL sample loops.

You can also purchase 5-, 10-, 20-, 50-, and 100-µL sample loops.

Vent Valve

Allows you to direct flow from the pump directly to waste, or through the injector, columns, and the rest of the system.

Physical Specifications

|

Wetted Surface Material |

Stainless steel (616 LC system) |

|

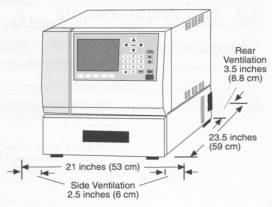

Controller |

Height: 7.19 inches (18.26 cm) Depth: 21.75 inches (55.25 cm) Width: 11.32 inches (28.75 cm) Weight: 33 lb (15 kg) |

|

Pump |

Height: 9.625 inches (24.4 cm) Depth: 20.5 inches (52.1 cm) Width: 11.125 inches (28.3 cm) Weight: 60.2 lb (27.3 kg) |

Optional equipment:

Photodiode Array Detector 996

Obtaining complete spectral data no longer means compromising chromatographic sensitivity. The 996 PDA Detector has the chromatographic sensitivity of even the best tunable UV/Vis wavelength detector. Trace amounts of sample and minor impurities can be detected and quantitated accurately.

Advanced optics enhances sensitivity und detectability

Optical design innovations enable the use of 10 mm flow cells to provide a 67% increase in observed absorbance over PDA detectors with 6 mm flow cells.

The 996 PDA Detector flow cell features the patented Toper-Beam technology that reduces refractive index effects at the eluate/flow cell interface. This technology focuses maximum light intensity on the diode array and improves detectability by reducing noise resulting in improved sensitivity. What's more, advanced mathematical algorithms for the 996 detector improve detection by reducing baseline noise (Figure 5B).

Lamp optimization software maintains high signal-to-noise ratio

Reducing baseline noise is a key element in maximizing compound detection. To ensure consistent performance over time, special software unique to the 996 PDA detector automatically maintains a minimal noise level over the lifetime of the lamp The software selects an appropriate exposure time for the diodes based on lamp energy, mobile phase and wavelength-range. This optimization, automatically performed before each injection, requires no manual adjustments to the detector operating current, slit width, or diode resolution.

Waters 996 Photodiode Array Detector Gives You Confidence - Erases the Doubts.

You're developing an HPLC method for analyzing the composition of a high-value-added fine chemical. You're responsible for developing methods to check for impurities in a drug to treat hypertension. You ve been given the task of isolating a compound taken from a rare plant that is known for its curative powers.

With challenges like this, you may have to place your reputation and that of your lab at stake. Can you afford not to invest in technology that gives you confidence in your ability to deliver results that are the best they can be?

How do I know if this substance is really pure or isn't something else?

With Waters 996 Photodiode Array Detector, you can be confident that if there is an impurity in your sample, you'll find it; that your compound is really what you report it to be and not something else. Every spectral detail of your sample is rapidly, easily, and accurately detected. Every peak is analyzed with mathematical precision so you can be sure your ability to assess the purity of peaks and confirm their identity is state-of-the art. And you will never have to trade off resolution for sensitivity.

Confidence in results through technological innovation

The 996 Photodiode Array Detector represents the most powerful combination of software and optics uniquely integrated to provide speed, detectability, and ease-of-use. Built into the 996 PDA Detector are technological innovations for obtaining the most complete and accurate spectral data of any photodiode array detector available today - designed to greatly enhance your ability to do more with the time you have and give you more confidence in the integrity of your results.

Absorbance measurement over the entire 190-800nm wavelength range (or for any pre-selected wavelength range) to-obtain as detailed a spectral map as possible.

Powerful Millennium ® software routines with advanced mathematical algorithms give you the rare ability to see the finest spectral details of even trace analytes. With Millennium Software you can extract wavelengths, calibrate, quantitate, determine peak purity, perform library comparisons, check system suitability, calculate RSD's, print custom reports and export all data automatically and without time consuming, post-run, manual calculations.

Advanced Taper-Beam optics for exceptional signal-to-noise performance and the linearity you need to analyze major peaks and minor impurities in the same run.

Validation and quality begin with our ISO 9000-certified manufacturing process

To assure product quality, reliability, und consistency, Waters instruments, data management systems und chemical products are developed and manufactured in accordance with Waters Total Quality Management (TQM) programs. Manufacturing operations are defined by written SOP's und specifications und are cerfified to ISO 9000 International Quality Management Standards und comply with cGMP requirements, Certificates of Validation are supplied with most products to verify that product design has been validated using a System Development Life Cycle (SDLC) process.

From installation to scheduled maintenance, Waters expertise in compliance und quality management is available to assist you in meeting ISO 9000 and regulatory requirements.

Qualification workbooks from Waters form the foundation for your Laboratory Validation Master Plan. Module and system level SOP's (IQ, OQ, PQ) guide you through installation, operation and maintenance for both instrument und data products.

Specially trained and certified Validation Support Specialists are available to assist you by providing maintenance and qualification services.

Optional Preventative Maintenance und Total Protection Service Plan coverage can be enhanced to include qualification services.

Operating Specifications

Wavelength range 190-800 nm

Light source Deuterium arc lamp

Spectral resolution 1.2 nm per photodiode (digital and optical)

Wavelength accuracy ± 1 nm

Linearity range 5% over-0.1 to 2.0 AU

Propyl paraben, 257nm

Baseline Noise ±1.5 X 10 5 AU at 254 nm (10mm cell)

Drift <1 X 10 3 AU/hour at 254 nm

Sensitivity setting range 0.0001-2.0 AUFS (under software control)

Taper Beam flow cells Cell Pathlength/volume

Standard analytical 10 mm/ 8 µl

Semi preparative 3 mm/2.5 µl

Inert 10 mm/8 µl

High pressure 10 mm/8 µl

Microbore 3 mm/2.5 µl

Outputs Two analog integrator outputs

Two programmable event outputs

Physical/Environmental Specifications

Dimensions Width:11,5 inches (29 cm)

Height: 5;9 inches (15 cm)

Depth: 22 inches (56 cm)

Weight 34 lb. (15,4 kg)

Temperature Operating: 4 to 40°C (39 to 104°F)

Humidity Operating: 20 to 80%, non-condensing programmable lamp shutoff

Electrical Specifications/Requirements

Power requirements 115 VAC (90-132 V), 50/60 Hz

230 VAC (190-264 V), 50/60 Hz

Power consumption 100 VAC (nominal)

Optional

Autosampler 717 Plus

Description

The Waters 717plus Autosampler injects samples into a high performance liquid chromatography (HPLC) system. The Waters 717plus automates sampling by storing up to 96 sampling methods or "steps". Each method controls all injection parameters for a sequence of vials.

The Waters 717plus may be used as either a stand-alone unit or as a component in a Waters IEEE-488 based HPLC system. As part of an IEEE-488 based system, the autosampler may be controlled by Waters PowerLine System Controllers or Waters Data Workstations.

The Waters 717plus autosampler features:

Sample carousels and vials

Two carousel sizes:

48-vial carousel - Holds 4 mL sample vials

96-vial carousel - Holds 1 mL sample vials

Multi-method automatic sampling

An auto sampling multi-method may contain:

Up to 96 steps, with each step containing a different sampling method

Random access to any single or series of vials

Priority (Stat) sampling

The Stat function:

Interrupts a programmed sampling method.

Performs injections from a single vial or a series of vials.

Returns to the interrupted sampling method, and continues auto sampling from the Interruption point.

Automation options

The 717plus allows you to program the following options:

Auto Addition - Allows you to inject a common solution with each sample.

Auto Standards - Allows you to run standards automatically during a run.

Auto Transfer -Allows you to program the 717plus to transfer solutions from specified vials to your sample vial; to mix the solution; and to inject.

Interaction with other LC modules

The Waters 717plus sends and receives signals from other LC modules, including:

Inject Start - Occurs when the sample is injected into the mobile phase stream. Initiates data acquisition, fraction collection, and detector autozero. Contact closure is initiated by the autosampler.

Inject Stop - Occurs when the programmed run time expires. Signals data integrators that the chromatography run is complete. Contact closure is initiated by the autosampler.

Hold - Halts the autosampler until the signal changes. Can be used to prevent sample injections if an LC system module fails or while a data acquisition system is preparing for the next run. Signal is received from external devices.

Report Delay - Delays the next injection until a data integrator can complete a report for the previous run. The delay is a programmable interval that occurs after the Inject Stop signal.

Programmable Event - The 717plus includes a programmable event output that can control external devices during a run.

IEEE-488 bus communication

As part of a Waters IEEE-488 system, the Waters 717plus autosampler accepts programming and control signals from an LC System controller.

RS-232 communications

The Waters 717plus autosampler sends data over an RS-232 communication line. The data is in ASCII format.

Purge and compression

Purge and compression testing copability includes:

Purge - Fills the sample loop and iniection syringe with fresh mobile phase.

compression - Tests the sample loop for gas content (compressibility). Compressibility limits may be set for specific mobile phases. Testing may be automatic or Operator initiated.

Needle wash system

Prevents Cross-contamination of samples

Extends seal life by removing the mobile phase and the sample from the sampling needle

Semiprep chromatography

For semiprep chromatography (up to 2 mL iniections), the 717plus autosampler may be configured with optional:

2000 µL sample loop - Required for iniections greater than 200 µL

2500 µL syringe - Speeds pre-iniection sequence for samples greater than 150 µL

Microbore (<1µL) Chromatography

For microbore chromatography, the 717plus autosampler may be configured with:

25 gL syringe for improved iniection volume precision below 1.0 µL

Low volume sample vials

Syringe speed

The autosampler syringe speed is adiustable for each syringe size and allows you to adiust for sample viscosity.

Heater/Cooler

The Waters 717plus Autosampler may be configured with a heater/cooler to maintain constant sample compartment temperature from 4 to 40°C.

Weight

Requires a bench capable of supporting at least 75 lbs.

Power requirements

Requires 6 Amps at 110 Vac (nominal) or 3 Amps at 220 Vac (nominal) from a grounded outlet.