Tecan Genesis WS150/4

| Objektnummer | B00010280 |

|---|---|

| Seriennummer | 010280 |

| Object Naam | Tecan Genesis WS150/4 |

| Status | Stock unit |

Product groep: DNA Sequencer

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Overview

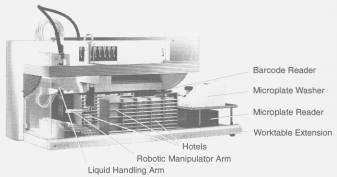

The Assay Workstation consists of:

Assay Workstation Base Unit with cutout Worktable

Extension Kit (Worktable Extension)

Customer's choice of options and accessories.

Figure 1 - 1 GENESIS Assay Workstation 150/8 equipped

Figure 1 - 2 GENESIS Assay Workstation, Worktable equipped

Intended Use

The GENESIS Assay Workstation is intended for processing of microplate based tests, including liquid handling, incubation, wash, read and data acquisition. lt is to be applied exclusively in the research field.

The GENESIS Assay Workstation is intended to be part of a liquid handling system and as such installed and put into Operation by a trained System Integrator.

Unintended Use

Due to its open architecture, the GENESIS Assay Workstation is NOT intended for clinical and diagnostic applications. These applications would be carried out by less qualified people, exposing them to dangerous liquids in case of Instrument malfunction.

Do not attempt to use liquids with undissolved particles as this could result in liquid not being dispensed due to clogged tips.

Carefully observe the Safety Instructions in Chapter 2.

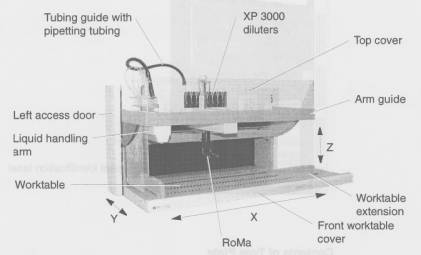

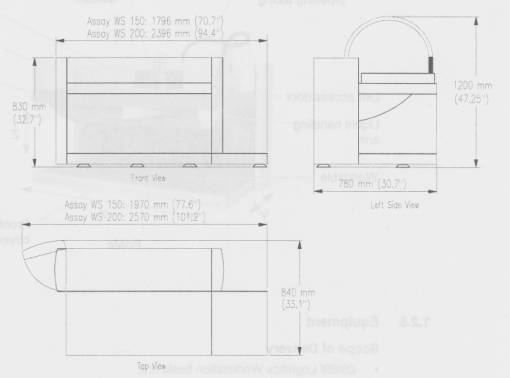

Assay Workstation, Basic Instrument

The Assay Workstation is produced in two different sizes, the arm is available with four or eight tips. 150 or 200 stands for the approx. instrument width in cm (without the worktable extension), the extension /4 means it is a 4-tip arm, /8 an 8-tip arm.

Figure 1 - 5 GENESIS Assay Workstation 150/8

Overview

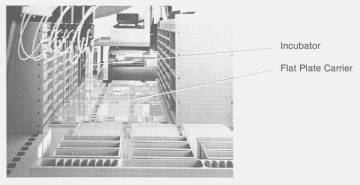

The Logistics Workstation consists of:

Logistics Workstation Base Unit with RoMa

TECAN Carousel

Customer's choice of options and accessories.

Figure 1 - 6 GENESIS Logistics Workstation 150/8

Intended Use

The GENESIS Logistics Workstation is intended for pipetting tasks as well as storage, identification and transfer of microplates. lt is to be applied exclusively in the research field.

The GENESIS Logistics Workstation is intended to be part of a liquid handling system and as such installed and put into Operation by a trained System Integrator.

Unintended Use

Due to its open architecture, the GENESIS Logistics Workstation is NOT intended for clinical and diagnostic applications. These applications would be carried out by less qualified people, exposing them to dangerous liquids in case of instrument malfunction.

Do not attempt to use liquids with undissolved particles as this could result in liquid not being dispensed due to clogged tips.

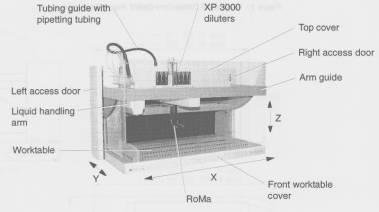

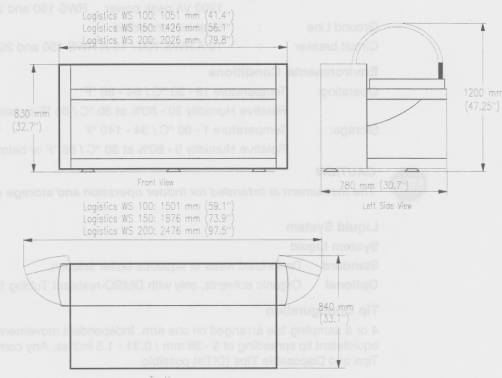

Logistics Workstation, Basic Instrument

The Logistics Workstation is produced in three different sizes, the arm is available with four or eight tips. 100, 150 or 200 stands for the approx. instrument width in cm (without the worktable extension), the extension /4 means it is a 4-tip arm, /8 an 8-tip arm.

Figure 1 - 9 GENESIS Logistics Workstation 150/8

Specifications

Assay Workstation

Overall Dimensions

Figure 1 - 10 Overall Dimensions GENESIS Assay Workstation

Weights

|

|

150 |

200 |

|

Assay Workstation with 4-tip arm |

131 kg / 288 Ibs |

181 kg / 400 Ibs |

|

Assay Workstation with 8-tip arm |

138 kg / 295 Ibs |

188 kg / 414 Ibs |

|

Packing |

50 kg / 111 Ibs |

74 kg / 163 Ibs |

Worktable Dimensions

|

X-Range: |

WorKstation 150 925 mm Workstation 200 1525 mm |

|

|

Y-Range: |

418 mm |

total range from first to last Tip |

|

|

364 mm |

common range for all tips on 4-Tip Arm |

|

|

292 mm |

common range for all tips on 8-Tip Arm |

|

Z-Range: |

165 mm |

with Standard Tip |

|

|

185 mm |

with DiTi 200µl |

|

|

150 mm |

with DiTi 1000µl |

|

|

195 mm |

with LV DiTi 10µl |

Logistics Workstation

Overall Dimensions

Figure 1 - 11 Overall Dimensions GENESIS Logistics Workstation

Weights

|

|

100 |

150 |

200 |

|

Logistics WS with 4-tip arm |

104 kg / 230 Ibs |

123 kg / 271 Ibs |

173 kg / 381 Ibs |

|

Logistics WS with 8-tip arm |

111 kg / 245 Ibs |

130 kg / 286 Ibs |

180 kg / 397 Ibs |

|

MPO or FWO |

2 kg / 4.4 Ibs |

2 kg / 4.4 Ibs |

2 kg / 4.4 Ibs |

|

Packing |

35 kg / 77 Ibs |

47 kg / 104 Ibs |

71 kg / 156 Ibs |

Worktable Dimensions

|

|

100 |

150 |

200 |

|

Accessible X-range |

745 mm |

1120 mm |

1720 mm |

|

(X-travel) |

(29.3") |

(44.1") |

(67.7") |

|

Accessible Y-range |

418 mm |

418 mm |

418 mm |

|

(Y-travel) |

(16.5") |

(16.5") |

(16.5") |

|

Pin Columns |

30 |

45 |

69 |

Specifications applying to both Assay and Logistics WS

Supply Ratings

Primary Voltage: 100 - 240 VAC

Line Frequency 50 - 60 Hz

Secondary Voltage: 24 VDC

Power: 800 VA peak power RWS 100

1200 VA peak power RWS 150 and 200

Ground Line: Must be connected

Circuit breaker: 10 A RWS 100 / 15 A RWS 150 and 200

Environmental Conditions

Operating: Temperature 18 - 30°C / 64 - 86°F

Relative Humidity 30 - 80% at 30°C / 86°F or below (non condensing)

Storage: Temperature 1 - 60°C / 34 - 140°F

Relative Humidity 5 - 80% at 30°C / 86°F or below (non condensing)

Liquid System

System Liquid

Standard De-ionized water or aqueous buffer solution.

Optional Organic solvents, only with DMSO-resistant Tubing Set 619 417.

Tip Configuration

4 or 8 sampling tips arranged on one arm. Independent movement in Z-direction. In Y equidistant tip spreading of 9 - 38 mm / 0.31 - 1.5 inches. Any combination of Standard Tips and Disposable Tips (DiTis) possible.

Syringes, Tips

Syringe Volumes 250µl to 5 ml; with Low Volume Option 250µl and 500µl.

Free Dispense Volumes of 3 µl to max. syringe volume or max. DiTi volume.

With Low Volume Option 0.5µl to max. syringe volume or max. LV DiTi volume.

Precision* (TECAN Quality Control requirements)

TECAN guarantees the following values for free dispensing (single pipetting mode, with water). Tip Touch significantly improves these values.

Volume Fixed Tip DiTi 200 LV Fixed Tip LV DiTi 10

100µl CV ≤ 0.5% CV ≤ 0.5% - -

10µl CV ≤ 3% CV ≤_3% CV ≤ 3% CV ≤ 3%

1µl - - CV ≤ 10% CV ≤ 10%

* Values are valid only if maintenance instructions and schedule have strictly been followed.

Carryover

< 10 -6 with Standard Tips and Monitored Pump Option.

Liquid Detection

Detection of conductive liquids of ≥ 50 µl (in microplates with round bottoms).

Robotic Manipulator Arm

Force in Z-direction 35 N

Transportable mass 0.4 kg

Gripper force 1...4 N

Gripper space range 55 to 140 mm

Rotation angle 280°

Minimum Computer Requirements

Hardware: min. PC Intel Pentium ® , clock rate ≥ 100 MHz

(recommended Pentium 200 MMX or Pentium II)

min. 64 Mbytes RAM (recommended 128 Mbytes RAM

Monitor VGA (1024 x 768)

Hard disk with 250 Mbytes free space

Floppy disk drive 3.5" 1.44 MB

CD - ROM

One free serial port RS-232 onboard and parallel interface (printer port)

Digi multiple serial port card (Digi AccelePort 8e-ISA DB25)

Operating System: Windows NT ® ≥ 4.0, Service Pack ≥ 3

Specifications

Barcode Reader

Laser Class: Class IIA

Power: 220 mA @ 5 VDC

Barcode Types

The optional Barcode Reader on top of the Hotel for Microplates recognizes the following Barcode Types:

Code 39 Code 128

Code 39 Full ASCII 2/5 Interleaved

Code 93 2/5 Discrete

Codabar UPC A and E (EAN 8 and 13)

The scanner autodiscriminates between these codes except for Code 39 and Code 39 Full ASCII.

Barcode Specifications

Barcodes to be in accordance with specifications ANSI X3.182 and DIN EN 1635.

Module width 7.5 - 15 mils (0.19 - 0.381 mm)

Quiet zone ≥5 mm

Print Contrast Ratio PCS >70%

Barcode height ≥ 8 mm

Barcode length max. 64 mm (without quiet zone)

Number of characters: max. 32

Black code on white background

Recommendations in regard to Barcode Quality

Use barcode testing device to verify barcode quality.

Quality Class A, B or C required. Identification of Class D is not guaranteed.

Print Quality: Use barcodes printed by thermal-transfer or photographic methods

Code label surface to be mat and clean

Do not use yellowed, dirty or damaged barcodes

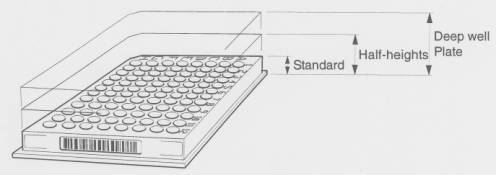

Barcode positioning

Figure 1 - 12 Barcode Label Position on Microplates