Perkin Elmer AAnalyst 700

| Objektnummer | B00024638 |

|---|---|

| Seriennummer | 024638 |

| Object Naam | Perkin Elmer AAnalyst 700 |

| Status | Gearchiveerd product |

Product groep: Atoomabsorptiespectrometer

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Firma: Perkin Elmer

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

The AAnalyst 700 Spectrometer System

Concept

The AAnalyst 700 spectrometer from Perkin-Eimer is a high performance atomic absorption spectrometer incorporating a burner system for flame atomization and a graphite furnace for electrothermal atomization. The spectrometer is capable of fully automatic single or multi-element analyses. The complete System is operated from the associated Computer using the AA WinLab software.

Features of the AAnalyst 700 System

Double-beam optical System optimized for maximum radiation throughput.

Two fully integrated atomizers: a burner system for flame atomization and a graphite furnace for electrothermal atomization. Atomizer changeover is automatic at the dick of a mouse button.

Longitudinally-heated graphite furnace featuring full Stabilized Temperature Platform Furnace (STPF) technology.

Deuterium background correction System.

Automated seif-optimization of the burner System.

High capacity furnace autosampler.

Easy-to-use AA WinLab software with which you control the spectrometer System. AA WinLab also incorporates a range of powerful quality control functions.

System components

The AAnalyst 700 is a compact benchtop spectrometer. The maj or components of the system are:

The spectrometer, containing the optical system, the electronics, and the atomizer compartment.

The bumer system, mounted an a carriage that can be driven into and out of the atomizer compartment by software command (see Burner design" in the Burner System User's Guide" for more information).

The graphite furnace, mounted an a carriage that can be driven into and out of the atomizer compartment by software command (see `Furnace design" in the `Graphite Furnace User's Guide" for more information).

The furnace autosampler, mounted an a swing arm in front of the atomizer compartment (see Autosampler design" in the `Graphite Furnace User's Guide" for more information).

The (optional) furnace cooling system (see `Cooling the furnace" in the `Graphite Furnace User's Guide" for more information).

The computer and the associated AA WinLab software.

The printer; this is optional but strongly recommended.

System control

To control the spectrometer and perform your analyses, you use the AA WinLab application program, which runs under the Microsoft Windows 95 operating system. The computer keyboard, the screen, and the mouse form the user interface.

When you switch an the spectrometer system it performs an initialization procedure to check the Instrument. While the spectrometer is operating, the control system continually monitors many Instrument functions. It generates appropriate messages when a problem occurs and prevents potentially hazardous situations from arising.

You can obtain more information about the application program in the AA WinLab online help.

Accessories

Perkin-Elmer offers autosamplers for operation with the bumer system, flow injection systems, diluters, and much more. Please contact your local PerkinElmer office to obtain more information.

The optical system

The AAnalyst 700 uses a double-beam optical system. Front-surfaced, reflecting optical components are used throughout. The mirror surfaces are coated with silica for durability.

The lamp compartment has positions for up to eight spectral sources. The radiation from the requested source lamp is reflected by a movable mirror into the optical path.

A beam splitter splits the radiation into a sample beam and a reference beam. The sample beam passes through the atomizer while the reference beam passes around the atomizer and is conducted by a Fiber optic. The sample and reference beams are measured simultaneously.

The Littrow-configuration monochromator has a large area reflecting grating blazed a two wavelengths; 236 nm for operation in the UV spectral range and 597 nm for operation in the visible spectral range. The monochromator offers a choice of three spectral slit widths. Two slit heights are available for each slit width. The high slits are used with the flame technique while the low slits are used with the graphite furnace technique. The detector is a segmented array of discrete photodiodes.

For continuum source background correction, the radiation from the deuterium lamp is merged with the source radiation at the beam splitter.

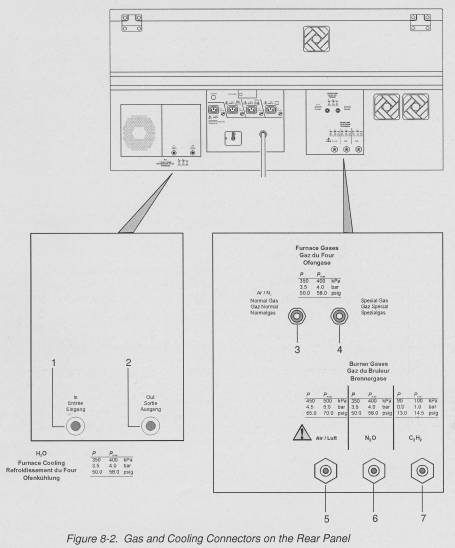

The gas and cooling connectors

Item Designation Function

Furnace Cooling

1 In Fitting for connection of the cooling water inlet hose to the

spectrometer.

2 Out Fitting for connection of the cooling water outlet hose from the

spectrometer.

Furnace Gases

3 Ar/N 2 Connector for the connection of the normal gas supply

Normal Gas to the furnace (argon or nitrogen).

4 Special Gas Connector for the connection of the special gas supply to the furnace.

If you are not using a special gas, you must also connect the normal

gas to this connector.

Burner Gases

5 Air/Luft Fitting for connection of the air supply to the spectrometer. The air

supply is required for the burner and also for the pneumatic system in

the spectrometer.

6 N 2 0 Fitting for connection of the nitrous oxide supply to the bumer.

7 C 2 H 2 Fitting for connection of the acetylene supply to the bumer.

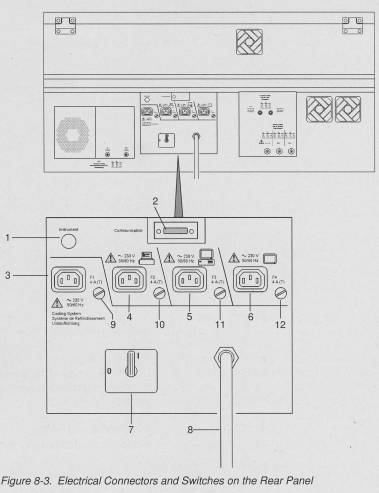

The electrical connectors and switches

Connectors and controls an the rear panel

Item Designation Function

1 Instrument Socket for a real cable to an external Instrument to activate a real

cycle.

2 Communic. Socket for the communication cable connecting the spectrometer to the

computer.

3 Cooling Syst. Power outlet for the cooling system. Connect the -.230 V 50/60 Hz

cooling system to this socket.

Do not connect other equipment to this power outlet.

4

Power outlet for a printer.

5

Power outlet for a computer.

6

Power outlet for a monitor.

7

Circuit breaker. An automatic switch that prevents the system from

drawing too much current. It can also be used to isolate the

spectrometer system from the line power supply.

8 - Captive line power cord for the complete System.

9 F1 Fuse for the cooling System Power outlet; 4 A slowblow (T).

10 F2 Fuse for the Printer Power outlet; 4 A slow-blow (T).

11 F3 Fuse for the Computer Power outlet; 4 A slow-blow (T).

12 F4 Fuse for the monitor Power outlet; 4 A slow-blow (T).

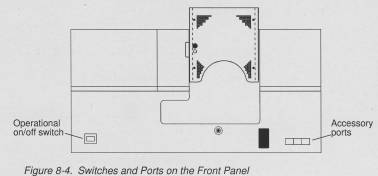

Switches and ports an the front panel

Operational an/off switches

You normally switch the system an and off with the operational an/off switch an the front panel of the spectrometer.

The cooling system requires a 230 V line power supply, which is supplied and controlled from the spectrometer. A special line power Cord is provided for this purpose. Do not connect the cooling system to an external power source. You can leave the an/off switch an the cooling system in the `on" position since the system is controlled from the spectrometer.

Accessory ports

Three accessory ports are located an the front panel of the spectrometer behind slicte-up covers. You use these Ports to connect certain accessories to the spectrometer, such as the furnace autosampler or a diluter.

The ports provide the electrical supply and control signals for operation of the accessories.

Technical data

Principle

Atomic absorption spectrometer.

Computer controlled, using a special application program running under a graphical user interface.

Real-time double-beam, all-reflecting optical system.

Front-surfaced optics protected by a silica coating.

AC modulated spectral line sources.

Monochromator

Littrow conflguration grating monochromator.

Grating:

ruled area: 64 mm x 72 mm, 1800 lines/mm

blaze wavelengths: 236 nm and 597 nm

Focal length: 267 mm

Slit widths 0.2, 0.7 and 2.0 nm

Wavelength range: 190-870 nm

Reciprocal linear

dispersion: 1.6 nm/mm (nominal)

Detector

Segmented discrete solid-state detector with CMOS charge amplifler array; software-controlled automatic gain control (AGC).

Lamps

Line radiation sources. Positions for up to 8 lamps in lamp compartment. Single- and multi-element hollow cathode lamps (HCLs) and up to 4 electrodeless discharge lamps (EDLs) can be used.

Background correction

Continuum source (deuterium lamp).

Atomizers

Flame atomization: Premix bumer system with pneumatic nebulizer and interchangeable bumer heads; automatic changeover between air/acetylene and nitrous oxide/acetylene flames.

Electrothermal atomization: Longitudinally-heated graphite furnace.

Signal handling

Time average, peak average, peak height, peak area.

Measurement ranges:

absorbance: 0.5 to 2.000

concentration: 0.00001 to 9999 concentration units

expansion factor: 0.01 to 100

read time: 1 to 60 s

read delay: 0 to 60 s

Calibration

Automatic zeroing, resloping, and recalibration.

Calibration/recalibration using up to 15 calibration solutions (standards').

Calibration coefficients determined by a least squares procedure.

Analytical curve technique:

Linear with zero or non-zero intercept.

Non-linear, 2-coefficient, or 3-coefficient, zero or non-zero intercept.

Analyte addition technique:

Zero or non-zero intercept.

Additions calibrate (zero intercept)

Computer (minimum requirement)

PC with Intel Pentium processor, 16 MB RAM, CD-ROM drive.

Hard disk space: 30 MB minimum free for AA WinLab, Database and

GPIB software, additional space required for storing results and methods.

Microsoft Windows 95 operating system.

Perkin-Elmer offers a suitable PC for controlling the spectrometer system.

Application program

Special application program: AA WinLab.

Online help function.

Hard disk or floppy storage of measurement data, signals, and completed analytical methods.

Special Reporter, Reformatter, and Library Manager applications for generating data reports and reformatting data for export to other data handling programs.

Graphics

High resolution display of the signals.

Simultaneous display of the corrected analyte signal and the background signal.

Calibration curve display.

Storage and recall of transient absorbance signals.

Hard copy printout of screen graphics an an associated printer.

Power requirements

230 V single-phase, 50 Hz, power consumption 3600 VA,

requirements -or‑

240 V single-phase, 60 Hz, power consumption 3600 VA

Electrical protection

As defined in EN 61010-1-1993 (IEC 1010-1):

Insulation: Class: I

Insulation category (Overvoltage category): II

Pollution degree: 2

Safety and EMC standards

EN 61010-1-1993 (IEC 1010-1:1990 + Al, A2, modified).

EMC standards EN 61010-2-061:1996

Electromagnetic compatibility:

EN 61326-1:1997

Environmental requirements

Ambient temperature: +15 °C to +35 °C,

20-80% relative humidity; non-condensing

Dimensions

Width: 1095 mm with handles: 1220 mm

Height: 655 mm with door open: 865 mm

Depth: 700 mm with handles: 770 mm with

autosampler: 1040 mm

Mass (weight)

147 kg

Spectrometer alone, not including the computer, autosampler, and cooling system.

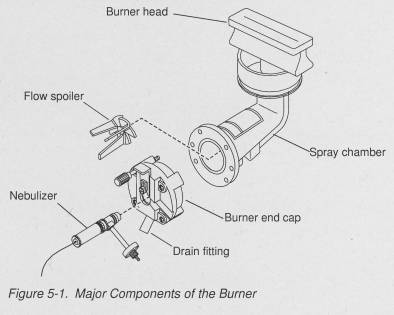

The Burner System

The burner System used in the spectrometer System is of the premix design. The measurement solution is sprayed by a pneumatic nebulizer into the spray chamber in the form of an aerosol. This aerosol is thoroughly premixed with the burner fuel and oxidant gares in the spray chamber. This gas mixture then passec through the burner slot into the flame.

The burner System is mounted an a carriage that can be driven into and out of the atomizer compartment by Software command. In this way you can change between flame atomization and electrothermal atomization easily within a few seconds.

The burner System comprises the following major components (see the Illustration below):

Nebulizer

Spray chamber with burner end cap and flow Spoiler

Burner head

Drain System (not shown)

Gas control System (incorporated in the spectrometer)

HGA Graphite Furnace

The HGA is a longitudinally-heated graphite furnace for electrothermal atomization in atomic absorption spectrometry. The furnace is electrically heated. The voltage is applied along the graphite tube, parallel to the radiation beam.

The graphite furnace is mounted an a carriage that can be driven into and out of the atomizer compartment by software command. In this way you can change between electrothermal atomization and flame atomization easily within a few seconds.

The power supply, system electronics, and the inert gas control pneumatics for the furnace are incorporated in the spectrometer. The electrical Gables and gas and water tubes to the furnace are led via a flexible conduit. The gas and electrical supplies for the furnace are controlled from the spectrometer.

Technical data

Graphite furnace

Principle Longitudinally-heated graphite furnace.

Temperature range Ambient temperature (20 °C) to 3000 °C,programmable in steps of 10°C.

Heating rate Programmable up to approx. 2000 °C/s (maximum power heating).

Gas Inert gas supply required for Operation (not provided); argon requirements recommended. A second, special gas can also be used.

Automatic gas shutdown when the furnace has been idle for 10 minutes. Pressure: 350-4-00 kPa (3.5-4 bar, 51-58 psig)

Gas flow: max. 1500 mL/min

Gas flows Intemal flow, selectable flowrates:

0, 50, 250 mL/min

External flow, flxed: 2 x 450 mL/min

Cooling Sediment-free tap water.

Water consumption: max. 2.5 L/min

Water pressure: max. 400 kPa (4 bar, 58 psig)

The use of the optional Recirculating Cooling System is recommended (see page 5-9 for the technical data).

Furnace program Up to twelve independent steps.

Parameters:

Isothermal temperature holding time: 0-99 s, in steps of 1 s Isothermal temperature: 20-3000 °C in steps of 10 °C

Heating rate: programmable, time-dependent or maximum power Intemal gas flow

Read delay

Read time

Safety features Automatic circuit breaker to prevent the furnace drawing too much current. Safety lock to prevent operation with the furnace open or with a defective tube.

Protection against overheating of the furnace or transformer.

Safety lock to prevent operation with low gas pressure.

The software continuously monitors the status of the system and informs the user of any Problems. If the user attempts to perform an action that could have serious consequences, suitable messages appear an the screen.

Power Integrated into the spectrometer; see the Technical Data for the

requirements spectrometer.

Electrical As defined in EN 61010-1-1993 (IEC 1010-1):

protection Insulation: Class I

I nsulation category (Overvoltage category): II

Pollution degree: 2

Safety and EMC As defined in EN 61010-1-1993 (IEC 1010-1: 1990 + Al + A2) and standards EN 61010-2-061:1996.

Electromagnetic compatibility: EN 61326-1:1997.

Environmental Ambient temperature: +15 °C to +35 °C

requirements 20-80% relative humidity; non-condensing

Cooling system

The recirculating cooling system is included with certain spectrometer systems and is offered as an option for others.

Principle Self priming recirculating system with fan-assisted heat exchanger.

Coolant 1:10 mixture of glycerine in deionized water or sediment-free drinking water.

Volume Approx. 5 L

Water Output: 36 °C ± 5 °C

temperature Inlet max: 90 °C

Fan cut-in temp: 40 °C

Flow 2,5 L/min

Air flow Approx. 400 m3/hour

Water pressure 300 kPa, (3 bar, 43 psig).

Pressure-sensitive safety switch shuts down the system if the internal pressure increases to above 650 kPa (6.5 bar, 95 psig).

Connections Reinforced hose, i.d. 8 mm; automatic connectors with integral shut-off valves.

Power 230 V, 50/60 Hz

requirements Power consumption: approx.140 VA

Dimensions Width:200 mm

Height:375 mm

Depth:500 mm

Mass (Weight) Approx. 18 kg with coolant.

Technical data

AS-800 Fumace Autosampler

Principle Random access fumace autosampler with programmable Sample volume. Can combine and dilute solutions automatically in the graphite tube and produce calibration solutions from a stock solution.

Control From the spectrometer's application program.

Sample trays Removable trays with 88 and 148 locations.

Rinsing A rinsing port is integrated with the sample table. This rinses the inside and outside of the pipet tip.

Minimum required 0.1 mL

sample volume

Pipetted volume Minimum: 1.011L; maximum: 99 µL.

For the best precision a minimum of 51.tL is recommended. Maximum = volume of one solution or the sum of individual solution volumes pipetted together; for example: [sample + matrix modifier + diluent + air bubble volumes]

Power requirem. The autosampler draws its Power from the spectrometer.

Safety and As defined in EN 61010-1-1993 (IEC 1010-1:1990 + Al + A2) and

EMC standards EN 61010-2-061:1996.

Electromagnetic compatibility: EN 61326-1:1997.

Environmental Arnbient temperature: +15 °C to +35 °C

requirements 20-80% relative humidity; non-condensing

Dimensions Dimensions without swing arm

Width:270 mm

Height:200 mm

Depth:340 mm

Mass (weight) approx. 7 kg including swing arm.

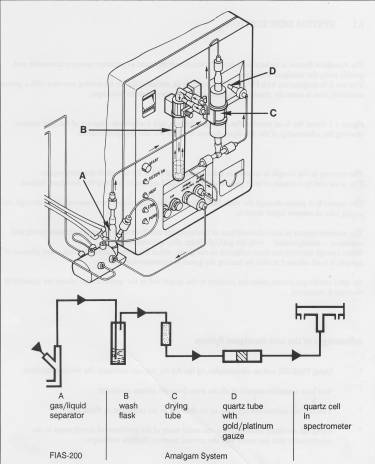

The Amalgam System

The Amalgam System is an accessory from Perkin-Elmer designed to measure mercury accurately and quickly using the amalgam technique.

You use it in conjunction with FIAS-200 and possibly an autosampler for measuring mercury with a greater sensitivity than is normally possible using the simple mercury/hydride technique.

Figure 1-1 shows the front panel of the Amalgam System, and a schematic diagram of the flow system, showing the relationship of the Amalgam System to FIAS-200 and the spectrometer.

The mercury in the sample is reduced in the Chemifold of FIAS-200 to atomic mercury vapour.

This is carried by a stream of inert gas out of the gas/liquid separator and into the Amalgam System.

The vapour first passes through the wash flask where soluble contaminants are removed, then through the drying tube to remove liquid droplets.

The mercury vapour is now relatively free of contaminants and flows over the gold/platinum gauze and combines - amalgamates - with the gold/platinum alloy quantitatively.

When enough mercury has been collected an the ganze, either from one sample or from many aliquots of a sample, it is all released at once by heating the gauze to approximately 600 °C.

An inert carrier gas stream takes the mercury to the quartz cell in the spectrometer where the quantity of mercury is measured.

Advantages of the new Amalgam System

* Using FIAS-200 and an autosampler, eg the AS-90, you can automate the whole procedure.

* You have complete control of all the steps from the system computer .

* You can use sodium borohydride or tin chloride as the reductant in FIAS-200.

* Using the amalgam technique you can avoid many of the problems of interference in the spectrometer that can occur with the normal mercury/hydride technique.

SPECIFICATION

THE AMALGAM SYSTEM

Principle A system for determining mercury using the amalgam technique.

Mode of The mercury is collected an a gold/platinum gauze. The gauze is then heated

Operation to release the mercury, which is carried to the spectrometer by a carrier gas.

Heating Two infrared lamps which heat the gauze to a temperature of approx. 600 °C.

Cooling Compressed air; pressure 320 - 400 kPa.

Carrier and Argon or nitrogen; pressure 320 - 400 kPa. Purge Gas

Flowrates Carrier - 75 mL/min

Purge - 300 mL/min

Power 105-125 V or 200-240 V, AC;

Requirements 50/60 Hz; 300 W.

Weight 8.5 kg.

Dimensions 240 x 240 x 240 (mm)

AS-70

SPECIFICATIONS

Sample trays Removable for quick change.

Sample tray capacity Locations for up to 40 sample cups. 1 additional container (for blank solution, for example).

Containers Up to 40 sample cups (depending an the number of reference solutions).

Option: up to 5 containers of 25 mL capacity (permitting up to 20 mL to be withdrawn) for matrix modifier or similar solutions.

Minimum sample requirement Approx. 0.1 mL

Dispensable sample volume 1 - 99 gL (AS-60) , 1 - 125 gL (AS-70) ,

selectable in increments of 1 µL.

Dispensable reagent volume 1 - 99 gL (AS-60) , 1 - 125 gL (AS-70) , selectable in increments of 1 µL.

Precision 5 µL 2% relative standard deviation

10 µL 2%

20 µL 1%

50 µL 0.5%

Accuracy 5 µL +/- 5%

10 µL +/- 5%

20 µL +/- 3%

50 µL +/- 2%

Maximum dispensable volume 125 gL (sum of indi.vidual solutions requested in a program step)

Rinsing volume 1.4 mL, fixed

Program start By soft key an the spectrometer keyboard.

Program stop Automatically after the last sample or at any preselected location, or manually via soft key an the spectrometer keyboard.

Power supply Via the HGA Power Unit.

Dimensions 280 mm wide x 200 mm high x 450 mm deep

(sample table assembly)

Weight (sample table ass.) Approx. 6 kg

AA WinLab

What You Need

Windows 95/NT or Windows 3.1x ?

In general AA WinLab Works best with Windows 957NT. For some Instruments you must use Windows 95/NT, for others you haue a choice. If possible we recommend that you use Windows 95/NT. The following table Shows which operating system you can use for which AA WinLab Instrument.

|

Instrument |

Windows 95/NT |

Windows 3.1x |

|

AAnalyst 600/7001800 |

Yes |

No |

|

SIMAA 6000 |

Recommended |

Yes |

|

FIMS |

Recommended |

Yes |

|

4110ZL |

Recommended |

Yes |

If you are installing an update, make sure that the computer has the correct specification for the new version of AA WinLab. The system requirements for Windows 95/NT and Windows 3.1x are shown an the pages that follow.

Firmware

The firmware is included with the AA WinLab software an the Installation disks. When you start AA WinLab for the first time, it automatically checks the firmware, and if necessary downloads the most recent version to the spectrometer. If you think there is a problein with the firmware or software, note the versions that are installed, then contact your local Perkin-Elmer office for further advice. To see the version numbers of the installed firmware and software:

1. Start the AA WinLab software.

2. In the Tools menu, click an Diagnostics.

3. On the Spectrometer, Furnace and FIAS pages you can see the firmware versions.

Computer system requirements for Windows 95/NT systems

To use AA WinLab v 3.1 with Windows 95 or Windows NT 4.0, you must have the following system components.

Windows 95: Minimum: Pentium, 90 MHz, 16 MB RAM

Windows NT 4.0: Minimum: Pentium MMX,166 MHz, 32 MB RAM Recommended: Pentium MVIX/Pentium II, 166 MHz, 32 MB RAM.

One bi-directional, parallel interface port.

CD-ROM drive, 1.44 MB, 3.5 inch floppy drive.

30 MB minimum free hard disk space for AA WinLab, database and GPIB software. Additional space is required for storing results and methods. Recommended: 1 GB hard disk.

Minimum: SVGA, 800x600, color graphics and a suitable monitor.

Recommended: 1064x768, color graphics and a 17 inch monitor.

Microsoft mouse or compatible mouse.

Windows-compatible professional printer. The following printers are known to work:

HP Deskjet 890 cxi

HP Laserjet 6L

Slot for a suitable GPIB IEEE card. This card and the correct GPIB software are provided with AA WinLab for new software installations.

Other software: AA WinLab and the Borland database engine are provided by Perkin-Elmer.

Note: If you are installing an update to AA WinLab, you must make sure that you have a suitable IEEE card. Make a note of the type of computer that you have and which IEEE card you have, then, call your Perkin-Elmer office for advice.

The IEEE card usually has a label an the mounting plate of the card. Look at the back of your computer; you may need to disconnect the IEEE cable to see the label.