IKA RW20

| Objektnummer | B00018083 |

|---|---|

| Seriennummer | 018083 |

| Object Naam | IKA RW20 |

| Status | Gearchiveerd product |

Product groep: Mixers / snijders

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Nachfolgende Abbildungen und Beschreibungen sind modellbezogen und aus Prospekten entnommen.

Sie geben nicht den Lieferumfang des Systems wieder.

Den exakten Lieferumfang entnehmen Sie bitte aus dem Angebotstext.

Bestimmungsgemäßer Gebrauch

Die Rührwerke der RW 20.n - Reihe eignen sich zum Rühren und Mischen von Flüssigkeiten niedriger bis hoher Viskosität. Sie sind für den Einsatz in Laboratorien konzipiert. Zum bestimmungsgemäßen Gebrauch müssen die Geräte mit einer Kreuzmuffe an einem Stativ befestigt werden.

Wissenswertes

Durch die handliche Form und die einfache Handhabung ist problemloses Arbeiten gewährleistet. Es können Drehzahlen von 60 bis 2000 1/min bei einer Netzfrequenz von 50 Hz und 72 bis 2400 1/min bei einer Netzfrequenz von 60 Hz eingestellt werden. Das Gerät erwärmt sich während des Betriebes. Die großzügig gestalteten Kühlflächen am Motor bewirken möglichst gleichmäßige Verteilung und Abstrahlung der Wärme. Das zwei Meter lange Netzkabel ermöglicht das problemlose Arbeiten an Stativen - auch

mit hochbauenden Glasapparaturen unter Dunstabzugshauben - ohne Verlängerungskabel. Die Präzisionsrührwelle ist als Hohlwelle ausgebildet und ermöglicht das Durchstecken der Rührschäfte im Stillstand.

Antrieb

Die Betriebsweise des Motors ist charakteristisch für das Betriebs-verhalten der RW 20.n Gerätereihe. Der Motor kann stufenlos über einem Reibradgetriebe verschoben werden und wird nur in einem Arbeitspunkt betrieben. Motorabgabeleistung, Motordrehzahl und Motordrehmoment werden als konstant angesehen und sind auf diesen Betriebspunkt hin optimiert. Nach dem Reibradgetriebe wird die Motorabgabeleistung wahlweise über die erste oder zweite Stufe des nachgeschalteten handverstellbaren Zahnradgetriebes an die Abtriebswelle des Rührgerätes weitergegeben.

Die Leistung an der Abtriebswelle ist bei Vernachlässigung aller Verluste, während der Energieübertragung (Wandlung) immer so groß, wie die vom Motor abgegebene Leistung. Im Getriebe erfolgt lediglich eine Drehzahl- und Drehmomentwandlung, die sich rein theoretisch in der in Fig. 4 dargestellten Kennlinie beschreiben läßt.

Der Reibradverschleiß wird durch eine an das Getriebe angepaßte Schraubenkupplung klein gehalten. Die am Reibrad notwendige Reibrad-Anpreßkraft wird von der Schraubenkupplung entsprechend dem an der Rührwelle wirkenden Momentenverlauf ausgeregelt. Bei einem kleinen Drehmoment wirkt eine kleine Anpreßkraft; bei einem großen Drehmoment wirkt eine große Anpreßkraft.

Um hochviskose Medien bearbeiten zu können, wurde bei der Type RW 20 DZM.n P4 auf die zweite umschaltbare Getriebestufe verzichtet und direkt hinter die erste Zahnrad-Getriebestufe ein Planetengetriebe mit einem Übersetzungsverhältnis von 3,7 : 1 geschaltet. Somit ergibt sich bei 50 Hz ein Drehzahlbereich von 16 bis 135 1/min und bei 60 Hz von 20 bis 160 1/min.

Getriebeumschaltung

Nur RW 20.n und RW 20 DZM.n

Muß während eines Versuchs- oder Prozeßaufbaues in einer Glasapparatur die Getriebestufe gewechselt werden, ist die Verschiebung des Rührwerkzeuges durch die exzentrisch aufgebaute Lagerbuchse und das Verschieben in axialer Richtung zu beachten. Kann dies nicht akzeptiert werden, muß das Rührwerkzeug im Spannfutter gelockert werden.

Durch Drehen ( im Gegenuhrzeigersinn ) der Lagerbuchse an der schwarzen gerändelten Oberfläche über dem Spannfutter werden die Zahnräder aus dem Eingriff gebracht. Die Mittelachse des Rührwerkzeuges verschiebt sich dadurch um 2,2mm in radialer Richtung. Anschließend wird die Lagerbuchse axial entsprechend dem einzustellenden Bereich nach unten oder oben um 5,5mm verschoben. Durch Zurückdrehen ( im Uhrzeigersinn ) der Lagerbuchse werden die Zahnräder wieder in den Eingriff gebracht und die Mittelachse des Rührwerkzeuges in die ursprüngliche Position geschwenkt.

Motorschutz

Der kugelgelagerte Kondensatormotor, Schutzart IP 42, ist wartungsfrei. Er trägt in seiner Motorwicklung einen speziellen Überhitzungsschutzschalter (selbsthaltender Temperaturbegrenzer) der bei Überschreiten der zulässigen Motortemperatur den Motor bleibend abschaltet.

Diese spezielle Schutzschaltertype wird verwendet, wenn ein auto-matisches Wiedereinschalten des zu schützenden Gerätes nach

Überhitzung unerwünscht bzw. nicht erlaubt ist. Das Prinzip des Temperaturbegrenzers ist das eines Schalters der bei Erreichen der höchst zulässigen Temperatur zum einen sich selbst beheizt und zum anderen den Motor von der Stromversorgung trennt.

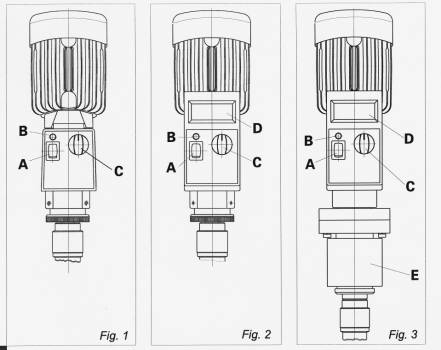

Beim Ansprechen des selbsthaltenden Temperaturfühlers leuchtet die gelbe Glimmleuchte (B) an der Frontseite des Gerätes auf und zeigt damit die Motorüberlastung und den Stillstand des Motors an. In diesem Falle kann das Gerät erst wieder in Betrieb genommen werden, wenn es durch Betätigen des Wippschalters (A) an der Frontseite oder durch Ziehen des Netzsteckers ca. 4- 5 Minuten aus-geschaltet wurde.

Nach dieser kurzen Abkühlzeit sind die Kontakte im Stromkreis wieder geschlossen und das Gerät ist wieder betriebsbereit.

Drehzahlanzeige

Die Drehzahl wird bei allen RW 20.n Rührgeräten über den frontseitigen Drehknopf (C) eingestellt.

RW 20.n

Beim Gerät RW 20.n wird eine definierte Drehzahl über die Skalierung der Drehknopfstellung eingestellt. Auf dem auf der Geräteseite angebrachten Schild ( Fig. 5 ) kann abgelesen werden, welche Drehzahl bei dem eingestellten Skalenwert erreicht wird. ( Die Werte gelten nur bei geringer Belastung an der Rührwelle )

RW 20 DZM.n

Beim Gerät RW 20 DZM.n wird die Dreh-zahl direkt in Umdrehungen pro Minute am LCD-Display (D) angezeigt. Die Anzeige kann nur maximal 1999 1/min anzeigen, was dazu führen kann, daß an der Abtriebswelle bei niedriger Rührwellenbelastung eine größere Drehzahl vorliegt als angezeigt werden kann.

RW20 DZM.n P4

Beim Gerät RW 20 DZM.n P4 wird die Drehzahl wie beim RW 20 DZM.n über das LCD-Display (D) direkt angezeigt. Der gesamte Drehzahlbereich kann, da das Zahnradgetriebe nicht mehr verstellbar ist und auf der kleinsten Stufe eingestellt ist, angezeigt werden.

Antriebswelle

Wenn das Gerät einige Zeit nicht benutzt wurde, ist nach dem Einschalten, bedingt durch die Vorspannkraft am Reibbelag des Reibradgetriebes, ein Klopfgeräusch zu hören. Für die Funktion des Gerätes ist dies nicht von Bedeutung. Das Klopfgeräusch verliert sich nach einer kurzen Einlaufzeit.

Spannfutter und Abtriebswelle gestatten das Einspannen und Durchstecken (außer RW20DZM.n P4) der Rührwerkzeuge bis 10mm Schaftdurchmesser. Durch die Offnung an der Gehäuseoberseite ist es möglich, Rührwerkzeuge z.B. beim Behälterwechsel bei Gerätestillstand über die Gehäuseoberkante hinaus zu schieben.

Zubehör

RW 20.n und RW 20 DZM.n

R 1823 Plattenstativ RH 1 Spannhalter

R 181 Kreuzmuffe FK 1 Flexible Kupplung

R 182 Kreuzmuffe

RW 20 DZM.n P4

R 2723 Teleskopstativ RH 2 Spannhalter

R 261 Kreuzmuffe R 263 Behälterklemme

R 271 Kreuzmuffe

Angewandte Normen und.Vorschriften

Angewandte EU-Richtlinien

EMV-Richtlinie: 89/336/EWG Maschinen-Richtlinie: 89/392/EWG

Aufbau nach folgenden Sicherheitsnormen

EN 61 010-1 /VDE 411-1 EN 60 2041

EN 50 081 EN 292-1, -2

EN 50 082-1 EN 414

EN 55 011 IEC 1010-1

EN 55 0141 UL 3101-1

EN 60 555-2, -3 CAN/CSA C22,2 (1010-1)

Technische Daten

Drehzahlbereich

(RW20.n / RW20 DZM.n)

( 50Hz Stufe 1 ) min -1 60 - 500

( 50Hz Stufe II ) min -1 240 - 2000

( 60Hz Stufe 1 ) min -1 72 - 600

( 60Hz Stufe 11) min -1 288 - 2400

(RW20 DZM.n P4)

( 50Hz Stufe I) min -1 16 - 135

( 50Hz Stufe II ) min -1 20 - 160

Max. Drehmoment Rührwelle

(RW20.n 1 RW20 DZM.n) Ncm 185

(RW20 DZM.n P4) Ncm 700

zul. Einschaltdauer: % 100

Drehzahleinstellung: Knebelknopf

Drehzahlanzeige:

(RW2o.n) Skala auf Gerätefrontseite

(RW20 DZM.n und RW20 DZM.n P 4) LCD - Display

Meßfehler: max. ±0,5% ±30 Digit

Nennspannung: VAC 230±10%

VAC 115±10%

Frequenz: Hz 50 EURO

Hz 60 USA

Aufnahmeleistung: W 72 EURO

W 87 USA

Abgabeleistung: (Kurzzeit) W 35

(Dauerbetrieb)W 20 +35%

Gesamtwirkungsgrad: % 40

Schutzart nach DIN 40 050: IP 20

Überspannungskategorie: II

Verschmutzungsgrad: 2

Schutz bei Überlast: Temperaturfühler in Motorwicklung

Sicherungen (auf Netzplatine):A 4 T (IKA-Ident Nr. 25 851 00)

Umgebungstemperatur: °C +5 bis+40

Umgebungsfeuchte: (Rel.) % 80

Betriebslage: am Stativ, Spannfutter nach unten gerichtet

Antrieb: Rippengekühlter Kondensatormotor mit Reibradgetriebe und nachgeschaltetem 2 stufigem Zahnradgetriebe.

(RW 20 DZM.n P4 auf Stufe 1 fest-gelegt; Planetengetriebe i=3,7:1)

maximale Rührmenge Wasser: Itr 20

für Viscosität:

(RW20.n 1 RW20 DZM.n) MV

(RW20 DZM.n P4) HV

|

Viskosität |

mPa . s |

|

|

|

VLV very low viscosity

|

0 100

100 1000

1000.. 10000

10000 100000 |

Wasser bis dünn‑ flüssiges Öl dünnflüssiges Öl bis dickflüssiges Öl dickflüssiges Öl bis Honig bei ca. 20 °C Honig bei ca. 20 °C bis Druckfarben |

|

|

LV Iow viscosity

MV medium viscosity

HV high viscosity

|

|||

Spannfutter-Spannbereich: mm 0,5 -10

Hohlwelle innen Ø: mm 10,5

Ausleger:

(RW20.n 1 RW20 DZM.n) mm 13x1601ang

(RW20 DZM.n P4) mm 16x1601ang

Gehäuse: Al-Druckguß, thermoplast. Kunststoff

RW20.n RW20 DZM.n RW20 DZM.n P4

Abmessungen ohne

Ausleger: (BxTxH) mm 88x188x292 88x210x292 88x210x402

Gewicht mit Ausleger

und Spannfutter:kg 2,9 3,1 4,6