Beckman SW 55Ti

| Objektnummer | B00014083 |

|---|---|

| Seriennummer | 014083 |

| Object Naam | Beckman SW 55Ti |

| Status | Stock unit |

Product groep: Centrifuges (rotors)

Status, leverings- en betalingsvoorwaarden

Apparatuurcontrole

De gebruikte apparatuur wordt voorafgaand aan levering gecontroleerd door Labexchange Service GmbH. U ontvangt volledig functionerende apparatuur.

Verzending

De vermelde verzendtijden zijn telkens de kortste voor een artikel. In bepaalde gevallen kunnen de daadwerkelijke verzendtijden daarvan afwijken. De uiteindelijke verzendtijden worden aangegeven in de opdrachtbevestiging.

In de regel bieden we combinatieleveringen aan. Levertijden zijn afhankelijk van het artikel met de langste levertijd. Deelleveringen zijn mogelijk tegen een toeslag.

Verzendmethoden

Koeriersdiensten, transportbedrijven, zelf afhalen, levering door Labexchange wagenpark

Informatie levering

De prijzen zijn exclusief verzendkosten. De genoemde verzendkosten zijn de te verwachten kosten. Afwijkingen zijn mogelijk. In het geval geen kosten voor verzending zijn gespecificeerd, vraag die dan afzonderlijk aan.

De opgegeven vracht- en verpakkingskosten hebben betrekking op de goedkoopste transportroute en zijn onder voorbehoud van onvoorziene kostenstijgingen. Door onvoorziene gebeurtenissen kunnen vrachttarieven en levertijden op elk moment veranderen en moeten ze worden aangepast aan de huidige situatie. Incoterm coderingen volgens Incoterms 2010: Bij afhalen EXW, CFR voor zendingen over zee, CPT per luchtfracht, andere zendingen DAP. Opmerking: We geven geen preferentieel certificaat/EUR1 af. Bij zelf afhalen/af fabriek (EXW) uit derde landen en de EU wordt 16% btw als borg ingehouden, tot we de ontvangstbevestiging/het leveringscertificaat van de koper hebben ontvangen.

Betalingsvoorwaarden

Wij accepteren geen betalingen Letter of Credit, PayPal etc. Het factuurbedrag is volledig verschuldigd. Er zijn geen betalingskortingen. De goederen blijven tot volledige betaling ons eigendom.

|

Land |

Mogelijke betaalmethoden |

Opmerking |

|

Duitsland, Oostenrijk, Zwitserland |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Nederland, België en Luxemburg |

Betaling via factuur, vooruitbetaling, per creditkaart |

Betaling via factuur is mogelijk voor ondernemingsklanten. |

|

Andere landen |

vooruitbetaling, per creditkaart |

|

Onze Algemene Voorwaarden voor Verkoop, Levering en Betaling zijn hierop van toepassing. Deze voorwaarden zijn hier te downloaden.

Tussenverkoop is ons voorbehouden.

Beschrijving status:

Alle artikelen zijn gebruikte artikelen, tenzij bij een artikel uitdrukkelijk wordt vermeld dat het om een nieuw apparaat gaat.

Firma: Beckman

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

SW 55 Ti ROTOR

(for use in Beckman Class B, C, D, F, G, H, Q, R, and S Preparative Ultracentrifuges)

DESCRIPTION

The SW 55 Ti swinging bucket rotor, rated for 55 000 rpm, is used in Beckman class B, C, D, F, G, H, Q, R, and S preparative ultracentrifuges. This rotor is designed to generate centrifugal forces for mang applications: concentrating viruses; separating DNA, RNA, or low molecular weight proteins in density gradients; and banding RNA-containing viruses in sedimentation equilibrium studies. Approximate sample volume per tube is 0.2 mL, with a gradient volume of about 4.8 mL.

The rotor body and buckets are made of titanium finished with polyurethane paint; the rotor body is black and the buckets are red. The aluminum handle and bucket caps are red anodized for corrosion resistance. The red SW 55 Ti buckets are similar in size to the black SW 50.1 buckets. DO NOT interchange the two types of buckets.

The bucket and cap assemblies hock over the Grossbar of the rotor hanger mechanism. Bucket 0-rings made of Buna N rubber maintain atmospheric pressure inside the buckets during centrifugation. Drive pins in the rotor drive hole prevent slippage of the rotor relative to the Instrument drive hub during acceleration and deceleration. In class G, H, R, and S Instruments, speeds exceeding 55 000 rpm are detected by means of an oversp,-led disk attached to the rotor bottom.

The SW 55 Ti rotor is warranted at maximum speed for 1000 runs, 2500 hours of centrifugation, or 5 years, whichever occurs first. If, after 1000 runs or 2500 hours of centrifugation, the 5-year warranty period has not expired, the warranty is then extended for an additional 1000 runs, or 2500 hours of centrifugation at any speed up to 90 percent of maximum.

SPECIFICATIONS

Maximum speed 55 000 rpm

Maximum solution density

1.2 g/mL

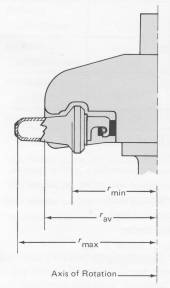

Relative Centrifugal Field* at maximum speed

At rmax (108.5 mm) 368 000 x g

At rav (84.6 mm) 287 000 x g

At rmin (60.8 mm) 206 000 x g

k factor at maximum speed (full tubes)

48

k" factors at max. speed (5 to 20% sucrose gradient; 5°C)

When particle density = 1.3 g/mL 135

When particle density = 1.5 g/mL 123

When particle density = 1.7 g/mL 118

Number of buckets 6

Available tubes see Tables 1 and 2

Nominal tube dimensions (largest tube) 1/2 x 2 in. (13 x 51 mm)

Nominal tube capacity 5 mL

Nominal rotor capacity

30 mL

Approximate acceleration time to maximum speed

(fully loaded, in L8M ultracentrifuge)

3 min

Approximate deceleration time from maximum speed

(fully loaded, in L8M ultracentrifuge) 3 min

Weight of fully loaded rotor 5 kg (11 lb)

Conditions requiring speed reduction see RUN SPEEDS

Rotor material titanium

-------------------------------

*Relative Centrifugal Field (RCF) is the ratio of the centrifugal acceleration at a specified radius and speed ( rw 2 ) to the standard acceleration of gravity (g) according to the following formula:

where r is the radius in millimeters, w is the angularvelocity in radians per second (2πRPM/60), and g is the standard acceleration of gravity (9807mm/s 2 ). After substitution:

TUBES

Tubes available for the SW 55 Ti rotor are listed in Tables 1 and 2. Be sure to observe the maximum speed Limits shown, and use only the tubes listed.

Temperature Limits

Polyallomer and polycarbonate tubes haue been tested for use at temperatures between 2 and 25°C, and Ultra-Clear TM tubes at temperatures between 4 and 20°C. Before use at other temperatures, these tubes should be tested under simulated run conditions. Polyallomer tubes should not be centrifuged below 2°C, as they may become brittle and Crack. Stainless steel tubes can be centrifuged at any temperature.

Filling and Sealing Tubes

Thinwall polyallomer and Ultra-Clear tubes should be filled to within 2 or 3 mm of the top for proper tube support. Thickwall tubes should be half-full to within 2 or

3 mm of the top for centrifugation. Stainless steel tubes can be filled to any level for centrifugation; however, opposing tubes should be filled to the saure level.

Quick-Seal tubes should be filled almost to the base of the neck. Do not leave

a large air space. Too muck air can cause the tube to deform, which may disrupt gradients or sample. Quick-Seal tubes are heat sealed, and spacers are required on top of the tubes when they are loaded into the rotor. See the instruction

bulletins on "How to Use Quick-Sea19 Tubes" (IN-163 and IN-181) for filling and sealing these tubes.

The g-Max TM system uses a combination of short bell-top Quick-Seal tubes and floating spacers (also referred to as g-Max spacers). Because Quick-Seal tubes are heat sealed they provide a secondary means of containment, making this system especially useful for centrifuging biohazardous or radioactive samples. Finally, the shorter pathlength of these tubes permits shorter run times. For more Information on the g-Max system, see publication DS-709.

Table 1. Available 1/2-in. Diameter Tubes for the SW 55 Ti Rotor

Only tubes listed either in this table or in Table 2 should be run in this rotor

|

Description |

Dimensions, (Inches) |

Part Number |

Maximum Volume (mL) |

Maximum Speed (rpm) |

|

Quick-Seal polyallomer* |

1/2 x 1 |

345829 |

2 |

55 000 |

|

Ultra-Clear |

112 x 2 |

344057 |

5 |

55 000 |

|

polyallomer |

112 x 2 |

326819 |

5 |

55 000 |

|

thickwall polyallomer |

112 x 2 |

349623 |

3.5 |

55 000 |

|

thickwall polycarbonate |

1/2 x 2 |

349622 |

3.5 |

55 000 |

|

Quick-Seal konical ** |

1/2 x 2 |

358647 |

3.2 |

55 000 |

|

konical *** |

1/2 x 2 |

358119 |

3 |

55 000 |

|

stainless steel |

1/2 x 2 |

305588 |

5 |

**** |

*Use floating spacer, p/n 355535, with this tube. Floating spacers, part of the g-Max system of tube Support, are made of Noryl, a registered trademark of General Electric.

** Use adapter, p/n 358153, and floating spacer, p/n 355535, with this tube.

***Use adapter, p/n 358153, with this tube.

****Read the section on RUN SPEEDS before using this tube.

Thinwall polyallomer konical TM tubes can also be used for pelleting Separations in the SW 55 Ti rotor. These tubes haue a conical tip to reduce working volume and minimize gradient chemical requirements, and come in both open-top and Quick-Seal designs. conical-cavity adapters hold the tubes in the rotor buckets.

See publication LR-IM for the care, cleaning, and chemical resistance of tubes and of rotor components.

Table 2. Smaller Tubes for the SW 55 Ti Rotor Only tubes listed

either in this table or in Table 1 should be run in this rotor

|

Description |

Dimensions and Volume |

Part Number |

Required Adapter |

Maximum Speed and RCF |

k Factor |

|

Ultra-Clear |

3/16 x 1 5/8 in. (0.8 mL) |

344090 |

356860 305527 |

48 000 rpm 269 000 x g 25 000 rpm 73 200 x g |

64 209 |