Varian Ultra Mass

| Objektnummer | B00012901 |

|---|---|

| Seriennummer | 012901 |

| Nome oggetto | Varian Ultra Mass |

| Stato | Archived Product |

Gruppo prodotti: ICP / MS

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representating the delivery volume. The exact delivery content you will find only in the offering text.

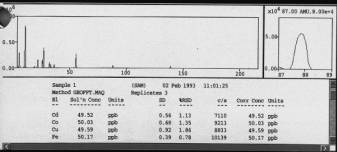

Specifications

Specifications Sample Introduction

Quadrupole mass spectrometer Assembly

Three stage differential vacuum pumping Siting Externally mounted

Vacuum Nebulizer Glass concentric

Two rotary pumps Spray chamber Inert "Sturman-Masters"

Two water cooled turbo molecular pumps Torch Low flow, low power

Twin cold cathode and twin thermocouple Nebulizer flow Mass flow controller adjusted by computer

gauges Plasma gas "Hammer" gas,computer-controlled

Startup/shutdown under computer control Auxiliary gas "Hammer" gas,computer-controlled

Quadrupole assembly Peristaltic pump 4 channel, 10 rollers, 0-50 rpm

One assembly with ion lenses, quadrupole computer-controlled

and ion detector mounted an one vacuum

flange RF generator

Ion lenses Operating frequency 40.68 MHz

All ion lenses under computer control Generator type Crystal controlled, solid state,

Detector water-cooled

Discrete dynode electron multiplier RF Coils "Turner" interlaced coils assembly

Positioning Plasma torch and coils, X, Y, Z , "Scout" protection prior to measurement position, under computer control

Software and hardware protection during

analysis RF power

Mass range Type Dual autotune impedance matchin

3-256 amu network

Resolution Efficiency 90%

0.5-1.5 amu under computer control Computer control 0-1.6 kW in 0.1 kW increments

(5% peak maximum) Plasma ignition Low stress pretuned

Power requirements system

3 phase star (WUE) configuration Interlocks Programmab.logic device,incl. gate

380/400/415/460/480 VAC valve water,argon,plasma compart.

± 5% (line to line) 50/60 Hz ± 1 Hz door, vacuum system

220/230/240/265/277 VAC Accessories/options

± 5% (line to neutral) 50/60 Hz ± 1 Hz

Rated current 11.2 amps per phase. SPS-5 autosampler Up to 5 racks of any user defined

The instrument may be connected to configuration

North American three phase delta 208 VAC Rack types Type 10 (10 mL x 100 positions)

supply by using a step-up auto Type 25 (25 mL x 60 positions)

transformer. Type 50 (50 mL x 35 positions)

Operating conditions Type A (125 mL x 12 positions)

From 18 to 22 °C (64 to 72 °F) Type B (500 mL x 6 positions)

From 50 to 60% relative humidity VGA-77P Vapor generator for impr. detection

(non-condensing) limits for As,Bi,Ge,Se,Sb,Sn,Te,Hg

Storage conditions

From 5 to 45 °C (41 to 113 °F) USN Ultrasonic nebulizer for improved

From 20 to 80% relative humidity detection limits

(non-condensing) "V" groove nebuli. Inert nebulizer suitable for

Instrument weight HF, fusions, etc.

530 kg (unpacked) Demountable torch Alumina or quartz injector tube

Instrument dimensions Cones Nickel or platinum sampler and

1640 mm (65") wide, 800 mm (32") deep skimmer cones

and 1210 mm (48") high. Compute r IBM or compatible, 486DX or . higher,33 MHz or higher, RAM 12 . Mbytes or more, hard disk 200 . Mbytes or more

Operating system OS/2 multi-tasking environment

Accessories

A range of accessories is available to provide a fully automated System capable of unattended operation. The SPS-5 Sample Preparation System has up to 500 tube positions, which can be used in conjunction with the other accessories which provide conventional nebulization, ultrasonic nebulization or hydride generation. Various rack combinations are available for a range of sample volumes, ensuring maximum flexibility for fully automated analyses.

Serviceability and remote diagnostics

UltraMass has been designed to allow quick and easy access to components for routine maintenance.

TeleDiagnostics TM provides facilities for the remote examination of results data files, analytical methods and error log data files. This minimises support call time, in turn reducing maintenance costs. Extra services, such as assistance with analytical methods also become available by remote communication.

Multi-Tasking software

Software

UltraMass uses the IBM OS/2 TM graphical user interface operating system. This provides full multi-tasking capabilities even allowing third party software to run concurrently. You can develop a method while an automated analytical procedure is proceeding. You can also monitor results, peak shapes and mass spectra scans at the same time. This greatly enhances your productivity, minimizing the time you spend waiting for the computer to complete a task.

Total computer control

All instrument parameters are centrally controlled by the computer. Analytical methods can be developed for individual applications and used in an automated analysis with any other developed methods for optimal results. Individual analytical methods may include different measurement modes and conditions for RF power, plasma gases, sampling depth and ion optics settings.

Quality Control Protocols

Full Quality Control Protocols (QCP) to cover anticipated US EPA requirements are built into the UltraMass software. You can choose QCP parameters and definable limits, ensuring maximum flexibility. In-run monitoring of analytical performance is achieved by the multiple windows facility of the OS/2 operating system. This can simultaneously display any of the following:

q Full mass spectra

q Zoomed regions for peak shape monitoring

q Analytical results with statistics

q `Live" continuous plotting of ion count rates for up to five selected species, or ratios.

A global picture of instrument status can be obtained in seconds, without moving from the computer.

Results editing facilities are available, together with customized printed results capabilities. Downloading of results after inspection of their quality integrity is easily achieved with the exporting facility, which includes filters to simplify data interpretation after downloading.

Automation wich confidence

All samples are subjected to "Scout"; a unique reconnaissance scan performed prior to analysis. This prevents damage to the detector by unforeseen high signals. "Scout" also improves productivity by eliminating the need for screening of unknown samples by other techniques such as ICP-AES or AAS.

Safe Operation

All instrument parameters are controlled by the computer. A programmable logic device is built into the instrument hardware, acting as a watchdog. All instructions are interrogated for safety and validity, providing an additional level of protection for you and the instrument.

Sample introduction

The external sample introduction assembly provides a stable environment for the spray chamber and nebulizer, unaffected by the temperature in the torch compartment. Easy access is provided for all components and accessories to allow rapid interchange. The inert Sturman-Masters spray chamber can be fitted with either a concentric glass nebulizer or an inert V-groove nebulizer. Both are an efficient means of producing an aerosol with very fine droplets, required to achieve the best signal and stability, while providing fast washout times. A four-channel, computer controlled peristaltic pump is standard, for versatility in sample presentation, including internal standard introduction.

Torch compartment

The plasma torch and the patented "Turner" interlaced induction coils assembly are mounted on a computer-controlled X, Y, Z plane translation assembly for accurate and reproducible positioning of the plasma. The "Turner" interlaced induction coils were specifically designed for ICP-MS. They contribute substantially to the efficient coupling of power into the plasma. This reduces interferences and improves the performance for organic samples. The torch compartment provides easy access to all components, including the interface between the plasma and the mass spectrometer. This will reduce the time spent on routine maintenance.

Power generation

The power for the plasma is generated by a computer-controlled, solid state, water-cooled RF generator, operating at the industry standard of 40.68 MHz. The UltraMass" coupling of the RF power into the plasma gives a measured efficiency of 90% - the highest yet reported for any ICP system. This high efficiency gives superb performance with organics, prolongs the life of components and contributes to the stability of results.

Vacuum system

The Varian turbomolecular and rotary pumps used in the UltraMass are computer controlled for simple, reliable start-up and shutdown. They are easily accessed for routine maintenance.

Mass spectrometer

The Varian-manufactured unit consisting of ion lens stack, quadrupole mass filter and detector assembly, can be removed and replaced easily by a trained person. This permits fast and easy cleaning of the ion lenses, ensuring good routine performance and improved productivity.