Spark Holland Marathon 810

| Objektnummer | B00013383 |

|---|---|

| Seriennummer | 013383 |

| Nome oggetto | Spark Holland Marathon 810 |

| Stato | Archived Product |

Gruppo prodotti: HPLC-Autocampionatori

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

INTRODUCTION

The MARATHON autosampler is dedicated to routine analysis of (arge series of samples in an environment where zero sample loss and injection flexibility are of Iittle significance but where reliability, stability and reproducibility is mandatory.The MARATHON therefore makes use of flushed loop injection only, guaranteeing reproducibility of injection better than 0.5 %.

For optimum stability and reproducibility of analysis, column temperature control is performed by the MARATHON itself with its unique feature: the built-in column oven!

Sample tray cooling

Sample tray cooling down to 3-4°C is provided as an option and uses a regular cryobath (not included in the option) to recirculate cooling water through the sample tray cooling device.

Large sample volumes

A special sample trag for 48 large sample vials (5 ml) can be obtained as an option. Loopfilling on a time base by sample headspace pressure can be selected for quick filling of (arge sample loops as an alternative to regular dispenser controlled Ioopfilling on a volume basis.

SPECIFICATIONS

Analytical

Sample capacity : 96 samples

(92, when needle wash is used)

Injection volume : flushed loop:

5 - 500 pl (dispenser controlled),

5 - >5000 pl (by headspace pressure).

Injections/vial : max 9

Analysis time max 99 min/59 sec

Needle wash : selectable

Reproducibility : better than 0.5%

Memory effect : less than 0.2%

Electrical

Power requirernents : 110 VAC ± 20% / 220 VAC ± 20%,

50/60 Hz, 50 VA (nominal).

Selectable an rear panel.

Control I/O : outputs:

(ref. also 3.2.2) - injectmarker (TTL + Contacts NO/NC)

- vial number BCD output (TTL) - stop I/O (TTL)

- auxiliary 1 (open collector)

- auxiliary 1 inverted (open collector)

- auxiliary 2 (open collector)

- auxiliary 2 inverted (open collector)

- 24 Volt DC (0.5 A max.)

inputs:

- stop I/O (TTL)

- freeze runtime (TTL) - next vial (TTL)

- next injection (TTL)

AIR supply : 4-6 bar clean and dry air.

(air dust filter standard in shipment kit)

Column thermostat

Temperature range : (ambient +5)°C - 80°

* time programmable second oven temperature

Temp. accuracy : ± 1 °C

Temp. stability : better than 0.5 °C

Options

Sample cooling : by external cryobath

via tray cooling, min. 3-4 °C

Temp. readout an display.

King Size tray : 48 positions for 5 ml vials

Micro injector : 0.5, 1, 2, 5 µl loop (RHEODYNE)

0.06, 0.1, 0.2 µl loop (VALCO)

PC control : SPARKLINK software for autosampler control.

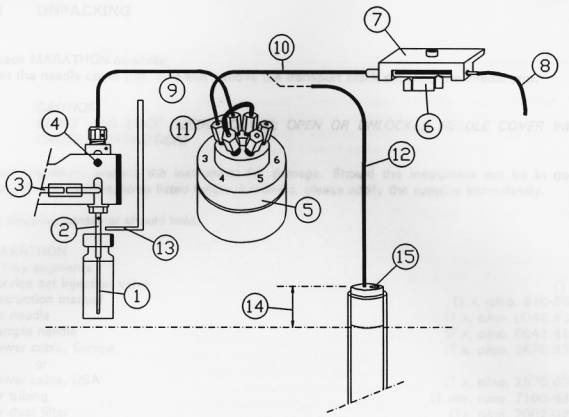

INJECTION PRINCIPLE

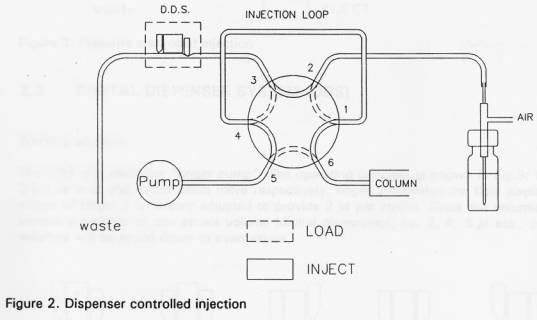

A six-port high pressure switching valve performs the injections based on the flushed loop principle. Loopfilling can be done on a volume basis, controlled by the digital dispenser System or on a time basis by headspace pressure on the sample (ref. SYSTEM SETTINGS, 5.3.1) to shorten filling time for larger loop volumes. The switching patterns of the valve in "LOAD" and "INJECT" Position are shown in fig.1. An injection is performed as follows:

DISPENSER CONTROLLED INJECTION

1. Dispenser sucks approximately 10 µl air bubble in sample needle for more efficient removal of previous sample.

2. With injection valve in inject position, the coaxial needle pair is inserted into the sample. Air pressure, applied to the sample through the outer air needle, ensures that no air or vapour bubbles are formed during sample withdrawal.

3. Dispenser withdraws "preflush volume" from sample vial to fill sample line with sample and to remove previous sample. (30 - 999 µl, programmable)

4. Injection valve switches into Ioad position; dispenser transports 2 or 3 x loopvolume through the loop to fill the loop quantitatively.

2 x loopvolume for loop equal to or larger than 100 µl,

3 x loopvolume for loop smaller than 100 µl.

5. Injection valve switches into inject position. Sample loop is now patt of the HPLC mobile phase flow path: sample is transported to the column. Analysis time starts.

If one injection is to be made out of each sample vial, the needle pair withdraws after analysis time and sequence 1-5 starts anew for the next vial. If more than one injection is to be made out of the same sample vial, the needles remain in the vial and after analysis time the next injection is made starting the sequence at 3 with a fixed preflush of 4 µl.

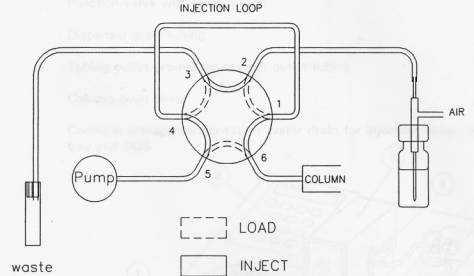

PRESSURE CONTROLLED INJECTION

1. With the injection valve in load position, the coaxial needle pair is inserted into the sample. Air pressure, applied an the sample through the outer (air-) needle, will force the sample via the inner (sample-) needle through the sample loop. The duration of the headspace pressure is programmable; appropriate duration has to be determined experimentally.

NOTE: A SPEC/AL SAMPLE DRAIN MUST BE CONNECTED TO THE INJECTION

VAL VE (REPLACING THE DISPENSER CONNECTIONI, REFER TO 4.2.4.3.

2. Injection valve switches into inject position. Sample loop is now part of the HPLC mobile phase flow path: sample is transported to the column. Analysis time starts.

If one injection is to be made out of each sample vial, the needle pair withdraws after analysis time and sequence 1-2 starts anew for the next vial. If more than one injection is to be made out of the same sample vial, the needles remain in the vial.

DIGITAL DISPENSER SYSTEM (DDS)

Working principle

The DDS is a miniature "finger pump". The operating principle is shown in Fig.3: Fingers 1 and 3 act as inlet and outlet pinch valve respectively, finger 2 provides the fluid displacement. The stroke of finger 2 is factory adjusted to provide 2 µl per stroke. Since the volume dispensed is always a multiple of one stroke volume (digital dispensing), i.e. 2, 4, 6 µl etc., odd values for volumes will be round down to even values.

Figure 4. Operating principle of digital dispensing System (DDS)

INSTRUMENT DESCRIPTION

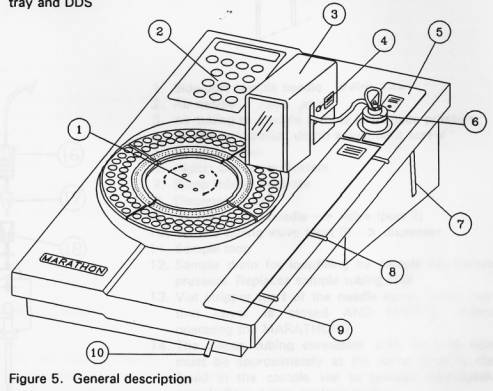

GENERAL DESCRIPTION

1. Sample tray, consisting of 4 removable segments

2. Keyboard and display

3. Needle cover

4. Needle cover locking screw

5. Dispenser cover

6. Injection valve with sample loop

7. Dispenser drain tubing

8. Tubing outlet groove for column outlet tubing

9. Column oven cover

10. Common leakage/condensation water drain for injection valve, oven, sample

tray and DDS

INJECTION SYSTEM

1. Side-port sample needle

2. Air needle

3. Air tubing to provide sample headspace pressure

4. Needle penetration depth adjustment screw

5. Injection valve

6. Digital Dispenser System

7. Pump tubing Cassette

8. Dispenser drain

9. Sample tubing needle --> valve (port 2)

10. Sample tubing valve (port 3) --> dispenser

11. Sample loop

12. Sample drain for loopfilling by sample headspace pressure. Replaces sample tubing (10)

13. Vial stripper (part of the needle cover, make sure that cover is closed AND LOCKED

before operating the MARATHON!)

14. The silicon tubing connector with air inlet hole must be approximately at the same level

as the liquid in the sample vial to prevent hydrostatic sample flow during analysis time.

15. Air inlet hole in connector to prevent emptying of sample vial by hydrostatic suction.

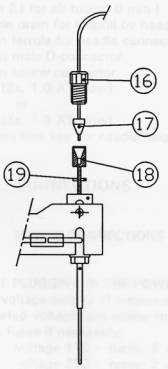

16. Needle connection nut

17. Ferrule (PTFE)

18. Sample needle connection hub

19. Air seal