Shimadzu AA-6300

| Objektnummer | B00017027 |

|---|---|

| Seriennummer | 017027 |

| Nome oggetto | Shimadzu AA-6300 |

| Stato | Archived Product |

Gruppo prodotti: Assorbimento Atomico (Fiamma e Grafite)

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

manufacturer: Shimadzu

model: AA-6300

annotation: Dokumente engl.

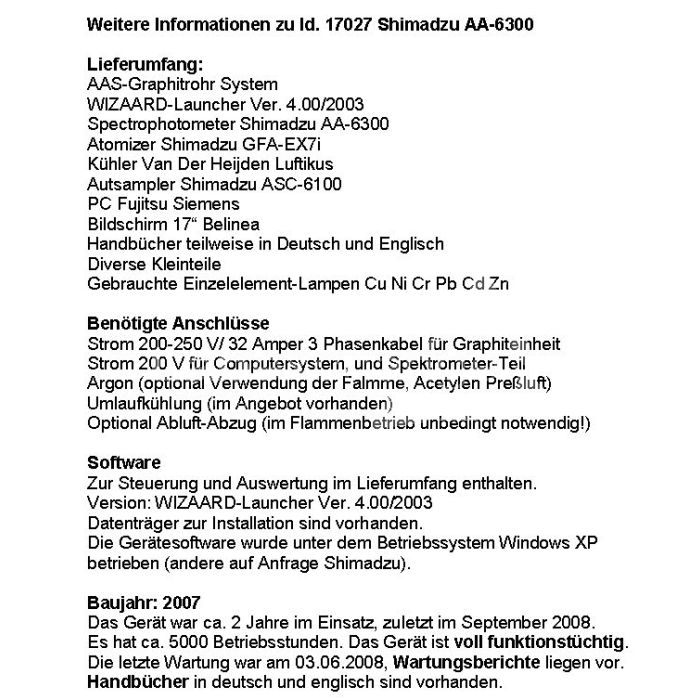

The following illustrations and descriptions refer to the instrument model and are drawn from brochures. They do not represent the scope of delivery. Please refer to the text of the offer for the exact scope of delivery.

Features

High-throughput Dynamic Beam Management System

- Ensures long-term stability with low noise level

- Provides the highest level of sensitivity for trace-level analysis (Direct determination - Flame: Pb, 0.1ppm; Furnace: Pb, 0.3ppb)

Dual-Detector System with Dual Background-Correction Function

- Ensures maximum sensitivity and accurate background correction at all wavelengths

- Easy selection process provides optimum method for meeting analysis objectives

Burner Height and Gas Flow Rates are Automatically Set for Each Element and Matrix

- Ensures maximum sensitivity and superior detection limits

- Enables continuous measurement

WizAArd Software - A Match for this Electronic Records Era

The newly developed "WizAArd" (Windows-based 32bit) software is much easier to understand and use, with a parameter editing function that enables conditions to be changed rapidly and comprehensive data processing functions. It provides a high level of electronic records security functions for compliance purposes:

- Manage user login ID names and passwords

- Manage authority restrictions according to user level

- Electronic signatures and audit trail functions have been equipped as standard

- QA/QC functionality as required by the U.S. Environmental Protection Agency (EPA) has been improved

- Hardware validation software is also standard.

Switch Smoothly Between Flame and Furnace - Without Tools

Simply remove the burner head and put in place the furnace section.

A single autosampler can be used for both flame and furnace, which negates the need to prepare the autosampler for each analysis method.

Comprehensive Flame Analysis

Highly Sensitive and Stable Flame Analysis

The High-Throughput Dynamic Beam Manager System developed uniquely for the AA-6300 automatically sets the photometric system to optical double beam for flame, and furnace measurement. Furthermore, the optical system has been designed to produce its maximum performance in each of the measurement methods through the optimal adjustment of the light beam, high-speed operation digital filter, and employment of optical components.

Flame Analysis under Optimal Conditions at All Times

The AA-6300 conducts measurements by automatically setting the optimal conditions for not just the gas flow rates, but also for the burner height for each element at all times.

Detailed methods - including the burner height - can be saved in files as measurement conditions, making it possible for anyone to conduct optimal measurements at any time.

Safe Flame Measurement

The following safety mechanisms have been incorporated.

- Safe ignition/extinction sequence

- Flashback prevention through the gas pressure monitor

- Prevention of raw gas release when the flame dies out

- Burner misuse prevention

- Automatic flame extinction in a power failure

- Safety inspection support provided by software, and a self-diagnostics function that determines whether the system safety mechanisms are in working order

Comprehensive Furnace Analysis

Highly Sensitive and Stable Furnace Measurement

Unique control of the gas flow inside the graphite tube at atomization (Patent 2067563) ensures high sensitivity measurement - among the best in the world. Combining a high-sensitivity optical sensor with a digital temperature control system enables temperature control with a high degree of precision over the entire temperature region from drying to atomization. By employing the electronic controller, the flow rate of the inner gas can be controlled precisely in 0.01L/Min units.

Furnace Analysis under Optimal Conditions at All Times

With a sophisticated autosampler, a maximum of 4 reagents (such as the diluent, standard solution, matrix modifier) plus sample can at first be mixed and then injected. The reagents can also be layered in any order.

The system can be set to automatically dilute and repeat the measurement if the calibration curve concentration is exceeded.

Safe Furnace Mechanisms

- Cooling water flow rate monitor

- (Ar) gas pressure monitor

- Over-current prevention device (double checked with the breaker and the optical sensor)

- Furnace block cooling check

Specifications

|

|

AA-6300 |

|

Wavelength range |

185 to 900 nm |

|

Mounting |

Aberration-corrected Czerny-Turner mounting, Number of grating groove:1800 lines/mm, Forcal length: 298mm |

|

Bandwidth |

0.2 0.7 0.7 2.0(Low) nm (4 step automatic switching) |

|

Detector |

Photomultiplier (short wavelengths), semiconductor (long wavelength) |

|

No. of lamps mounted |

6 lamps, 2 user-selected lamps can be illuminated at the same time |

|

Photometric Mode |

Flame: Optical double beam. Furnace: Double beam |

|

Background Correction |

High-speed Self-Reversal method (BGC-SR), high-speed deuterium lamp method (BGC-D2) |

|

Lamp Mode |

Emission, Non-BGC, BGC-D2, BGC-SR |

|

Burner Type |

Air-cooled premix type |

|

Burner Head |

Made of titanium, 10cm slot (the 5cm slot for high temperature flames is optional) |

|

Nebulizer |

Pt-lr capillary with teflon orifice and ceramic impact bead (Hydrofluoric acids can be used) |

|

Chamber |

Polypropylene |

|

Positioning Control |

Automatic search for the optimal burner height, automatic adjustment of vertical position, manual adjustment of back and forth position |

|

Gas Control - Flow Control Unit |

Fuel gas, support gas, automatic flow rate setting (0.1L/min step), automatic search for the optimal gas flow rate |

|

Safety Measures |

Safe ignition/extinction sequence |

|

Ignition |

Push ignite button |

|

Software |

Software based on Microsoft Windows TM |

|

Dimensions & Weight |

835 (W) x 460 (H) x 545 (D) mm, 70 kg (not including the flue, protruding parts) |

|

Power Requirements |

AC100V±10% (no sudden voltage fluctuations) |

|

Ambient Temperature and humidity range |

Temperature: 10 ~ 35°C |