Perkin Elmer Autos 200

| Objektnummer | B00013500 |

|---|---|

| Numéro d'identification | 013500 |

| Nom de l'objet | Perkin Elmer Autos 200 |

| Statut | Stock unit |

Groupe de produits: CLHP passeurs d'échantillons

Statut, conditions de livraison et de paiement

Vérification des appareils

Les appareils d’occasion sont vérifiés par Labexchange Service GmbH avant la livraison. Vous recevez des appareils entièrement fonctionnels.

Délai d'expédition

Les délais de livraison indiqués sont les plus rapides pour l’article en cause. Les délais de fait peuvent varier au cas par cas. Les délais de livraison définitifs sont indiqués dans la confirmation de commande.

Nous offrons des livraisons collectives par principe. Le délai de livraison s’oriente à l’article avec le délai de livraison le plus long. Une livraison partielle est possible par prix additionnel.

Méthodes d'expédition

Courrier, agences d'expédition, autocueillette, livraison par flotte de Labexchange

Conditions de livraison

Prix plus frais d’expédition. Les frais d’expédition indiqués sont à prévoir. Dérogations éventuelles sont possibles.

Si les coûts de transport ne sont pas spécifiés, s'il vous plaît demander séparément les frais de transport. Les frais de transport et d'emballage indiqués se réfèrent à l'itinéraire de transport le moins cher et sont sujets à des augmentations de coûts imprévues. En raison d'événements imprévisibles, les tarifs de transport et les délais de livraison peuvent changer à tout moment et doivent être adaptés à la situation actuelle. Incoterm codage selon les Incoterms 2010: Pour personnes qui viennent chercher les dispositifs elles-mêmes: EXW, pour les expéditions par voie maritime: CFR, par avion: CPT, d'autres expéditions: DAP. Remarque: Nous n'établissons pas des preuves préférentielles/EUR1. Dans le cas d’un enlèvement par vos soins/EXW de pays à l’intérieur ou à l’extérieur de la Union européenne, nous devons conserver 16% de TVA d’acheteur comme dépôt de garantie, jusqu’à ce que nous ayons reçu l’attestation de reception/la prevue de livraison.

Modalités de paiement

Nous n’acceptons pas le paiement par lettre de credit, PayPal, etc. Dans tous les cas le montant est payable sans déduction. Jusqu’au paiement complèt l’équipement reste notre propriété. Un escompte n’est pas accordé.

|

Pays |

Modalités de paiement possible |

Remarque |

|

DE, AT, CH |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

NL, BE, LU |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

Autre pays |

Prépaiement, par carte de credit |

|

Nos conditions de vente, de livraison et de paiement sont en vigueur. Vous pouvez télécharger les documents ici.

La vente intermédiaire nous est réservée.

Défintion des statuts

Tous articles sont d’occasion, sauf si explicitement défini comme « appareil neuf ».

|

Statut |

Condition |

Remarque |

|

Immédiatement disponible |

Occasion |

L’article a été déjà entièrement vérifié et peut être envoyé directement à vous. |

| En stock |

Occasion |

L'article est en notre stock, mais doit être vérifié avant la livraison par nos techniciens Vous recevez des articles entièrement fonctionnels. |

|

Publié |

Occasion |

L’article est toujours au l’offreur. Nous achetons, vérifions et en fin livrons l’article après votre commande. Le certificat de fonctionnement ainsi que le rapport de service sont inclus à la livraison. |

|

Appareil neuf |

Neuf |

C’est un dispositif neuf. L’article n’est pas utilisé et neuf d’usine. En ce qui concerne des article neufs, la garantie du fabricant est valable. |

|

Labprocure |

Occasion |

Responsable du contenu de l‘offre d’appareil est la société Labprocure GmbH, comme annonceur. Labprocure assume la responsabilité des offres annoncées ici ainsi que des photos et des textes d’offre inclus. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

The Series 200 LC Autosampler.

The Perkin-Elmer Series 200 LC Autosampler is an advanced sample processor that can be used with virtually every liquid chromatography system or application. You configure the Autosampler and define all of your methods and operations using function keys on a keyboard located on the front panel of the instrument. A backlit Liquid Crystal Display (LCD) located directly above the keyboard shows both status information about the instrument and provides access to the screens you use to define methods and set configuration parameters. If you use the Perkin-Elmer Series 200 LC Pump, you will find that the Autosampler front panel is almost identical to the one on the Pump. In addition, the Pump and the Autosampler share many common operating features that will allow you to get your system up and running quickly. The Series 200 LC Autosampler provides you with interchangeable technology so that you do not have to buy a new Autosampler and learn new user interfaces every time your needs change.

Series 200 LC Autosampler Features and Benefits

Upgradable to biocompatible versions for maximum flexibility.

Small, compact design (12.5 inches (31.8 cm) wide) saves valuable bench space.

Directory of up to 20 methods.

Ability to link up to 10 methods together in a sequence.

Priority method which allows you to interrupt a method or sequence to run critical samples. The method or sequence resumes once the priority samples are analyzed.

Edit the active method or sequence in real-time with easy access function keys.

Large backlit liquid crystal display allows clear viewing of autosampler method and operating parameters at all times.

Tactile keyboard with unique "key click" so that you know your entry has been made.

Phone type contact closure connections and finger tight plumbing fittings make it simple to connect or disconnect your system.

Full method documentation including modification with method name, number, date and time stamp.

Visual access front-door panel allows quick plumbing inspection and easy servicing.

Maintenance log coded by the serial number of the autosampler, including autosampler injection cycles.

Instrument log records history of operation for quick diagnosis and servicing to get you up and running quickly.

Extensive service diagnostics.

Sampler module can be completely removed to lab bench for maintenance without having to unstack modules.

Main Components of the Series 200 LC Autosampler

The Series 200 LC Autosampler consists of the following main components. A brief description of each of the components follows.

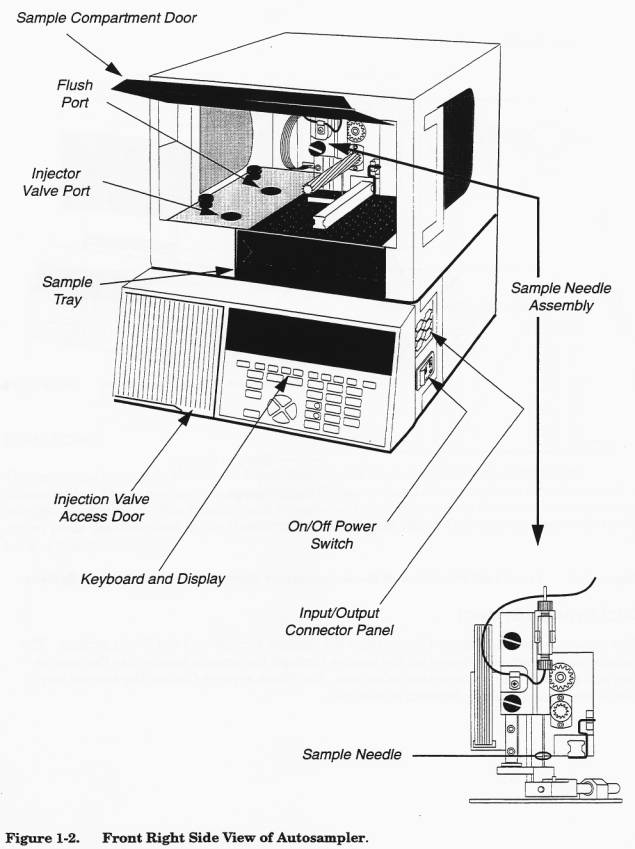

Refer to Figure 1-2 for the location of the following components.

Keyboard and Display

All instrument functions are accessed using the keyboard. Status information is shown on the screens appearing in the display. An overview describing how to perform some basic operations using keyboard and display is provided in "Using the Keyboard and Display" section of this chapter.

Input/Output Connector Panel

The connector panel consists of six contact closure connectors for automated instrument control of devices like an LC pump, LC detector, and a data handling system.

Sample Tray

The Autosampler accepts eight different types of sample trays. The trays hold sample and calibrant vials, as well as dilution and derivatization vials or tanks. For a complete list of available tray types, refer to Appendix A in this manual. The Autosampler identifies the tray type by reading the pattern of fingers on the back of the tray. When you load a tray, these fingers slide into a sensor which is recessed in the back wall of the tray well.

Sample Needle Assembly

This assembly consists of a sample needle that moves up and down (Z direction) and is mounted in a transport mechanism that moves backwards and forwards and left to right (XY direction). The sample needle picks up sample or calibrant from the vial and, depending on the method, performs dilutions and/or derivatization and injects the sample onto the column. It is connected to and works in conjunction with the Injection Valve Assembly and the Dual Syringe System. The Injection Valve Assembly is accessed through the Injection Valve Access Door. (The location of the Dual Syringe System is shown in Figure 1-3.)

During the sampling operation:

The transport mechanism positions the sample needle above the sample vial.

A cushion of air is drawn up into the needle.

The needle is lowered to just pierce the vial septum. At this point, the system verifies that the vial is present.

The needle is fully lowered into the vial and the required sample volume is drawn up.

The needle is raised clear of the vial and another cushion of air is drawn up.

The transport mechanism moves the needle to the Injection Valve Port.

The needle is lowered into the port and the sample is injected onto the column.

The transport mechanism moves the needle to the flush port and a flush cycle is performed.

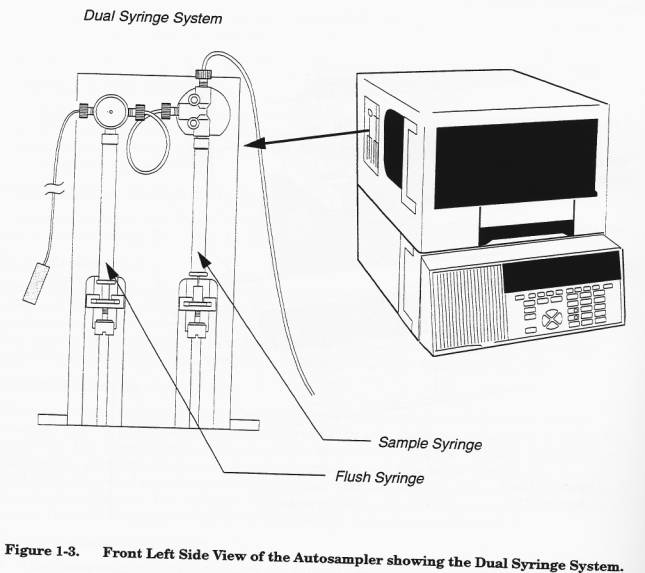

Dual Syringe System

This system, shown in Figure 1-3, contains the Sample syringe and the Flush syringe. The Sample syringe actually draws up the sample through the sample needle into the sample

loop and ejects it into the injection valve port. The Flush syringe flushes the sample loop, needle and sample tubing between injections.

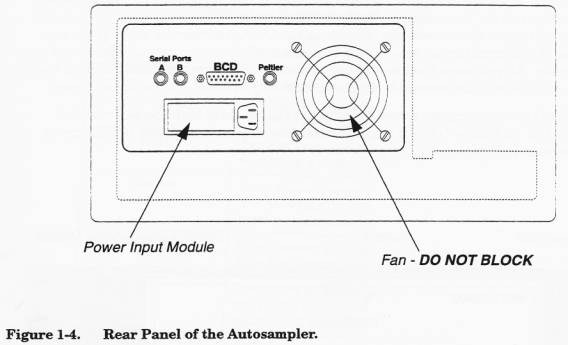

Rear Panel

The rear panel contains the Power Input Module and the communication ports for the Autosampler. The power module accepts the AC line cord and contains the System fuses and voltage selector card. The function and procedures required to set up the various communication ports are described in the "Defining the Communications Options" section in Chapter 3 of this manual.

Instrument Specifications

Specification Description

Injection range Programmable from 0.1 - 1.0 µL at 0.1 µL increments, 1 µL to 2.5 mL at 1 µL increments

Replicate injections 1 - 99 from one vial

Precision Typically <0.5% RSD of peak areas from 3 µL

Linerarity >0.999

Minimum sample volume 1 µL in 7 µL

Sample syringe sizes 50, 100, 250, 500, 1000, 2500 µL

Sample waste None (or user selectable)

Carryover <0.02%

Flush cycles User selectable, 1 - 9

Flush volume 0 - 2500 µL

Sample capacity up to 225 vials with optional tray

Method parameters Injection volume, sample draw speed, flush volume, flush cycle, 2 external contacts, start and stop time

Methods Battery-backed storage of up to 20 methods including time programming. Editing of stored methods possible during runs.

Injection cycle time 2 - 3 samples per minute

Valve materials in contact with With Rheodyne 7725 for Analytical - stainless steel, Vespel, sample ceramic, PEEK

With Rheodyne 9725 for Bio Applications - PEEK, Tefzel, ceramic

With Rheodyne 8125 for Microbore - stainless steel, Vespel, ceramic, PEEK

Display 7-line by 40-character backlit liquid crystal display

Communications Integrated communications for derivatization and dilution options

Serial communications - standard

BCD interface - standard

5 relay outputs; 2 timed events, 2 inject, 1 start

AC Power Requirements:

AC power 70 Watts

AC voltage range Grounded 100, 120, 220, 230, VAC (±10%) Grounded 240 VAC (+6%/-10%)

Frequency 50/60 Hz L1%)

Fuse rating characteristics:

100/120 VAC Single Fuse 1.6 A 3 AG Slow Blow, 250 V

220-240 VAC Single/Dual Fuse 0.8 A TT (5x20 mm), 250 V

Operating Conditions:

Environment This instrument is designed for indoor use. It is not designed to operate in an explosive environment.

Ambient temperature 10 - 30°C

Ambient relative humidity 10 - 80% (without condensation)

Altitude 0 to 2000 meters

Installation Category This instrument is able to withstand transient overvoltage according to Installation Category II as defined in IEC 1010-1.

Pollution Degree This instrument will operate safely in environments that contain nonconductive foreign matter to Pollution Degree 2 in IEC 1010-1.

Peltier sample cooling tempera- 4 - 50°C, ± 2°C

tune range

Storage Conditions:

Ambient temperature -20 to 60°C (-4 to 140°F)

Ambient relative humidity 10 - 80% (without condensation)

Altitude 0 to 12,000 meters

Dimensions Height: 400 mm (15.8 in)

Width: 318 mm (12.5 in)

Depth: 483 mm (19 in)

Weight 21 kg (461bs)