Heraeus M 104

| Objektnummer | B00013490 |

|---|---|

| Numéro d'identification | 013490 |

| Nom de l'objet | Heraeus M 104 |

| Statut | Stock unit |

Groupe de produits: Fours

Statut, conditions de livraison et de paiement

Vérification des appareils

Les appareils d’occasion sont vérifiés par Labexchange Service GmbH avant la livraison. Vous recevez des appareils entièrement fonctionnels.

Délai d'expédition

Les délais de livraison indiqués sont les plus rapides pour l’article en cause. Les délais de fait peuvent varier au cas par cas. Les délais de livraison définitifs sont indiqués dans la confirmation de commande.

Nous offrons des livraisons collectives par principe. Le délai de livraison s’oriente à l’article avec le délai de livraison le plus long. Une livraison partielle est possible par prix additionnel.

Méthodes d'expédition

Courrier, agences d'expédition, autocueillette, livraison par flotte de Labexchange

Conditions de livraison

Prix plus frais d’expédition. Les frais d’expédition indiqués sont à prévoir. Dérogations éventuelles sont possibles.

Si les coûts de transport ne sont pas spécifiés, s'il vous plaît demander séparément les frais de transport. Les frais de transport et d'emballage indiqués se réfèrent à l'itinéraire de transport le moins cher et sont sujets à des augmentations de coûts imprévues. En raison d'événements imprévisibles, les tarifs de transport et les délais de livraison peuvent changer à tout moment et doivent être adaptés à la situation actuelle. Incoterm codage selon les Incoterms 2010: Pour personnes qui viennent chercher les dispositifs elles-mêmes: EXW, pour les expéditions par voie maritime: CFR, par avion: CPT, d'autres expéditions: DAP. Remarque: Nous n'établissons pas des preuves préférentielles/EUR1. Dans le cas d’un enlèvement par vos soins/EXW de pays à l’intérieur ou à l’extérieur de la Union européenne, nous devons conserver 16% de TVA d’acheteur comme dépôt de garantie, jusqu’à ce que nous ayons reçu l’attestation de reception/la prevue de livraison.

Modalités de paiement

Nous n’acceptons pas le paiement par lettre de credit, PayPal, etc. Dans tous les cas le montant est payable sans déduction. Jusqu’au paiement complèt l’équipement reste notre propriété. Un escompte n’est pas accordé.

|

Pays |

Modalités de paiement possible |

Remarque |

|

DE, AT, CH |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

NL, BE, LU |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

Autre pays |

Prépaiement, par carte de credit |

|

Nos conditions de vente, de livraison et de paiement sont en vigueur. Vous pouvez télécharger les documents ici.

La vente intermédiaire nous est réservée.

Défintion des statuts

Tous articles sont d’occasion, sauf si explicitement défini comme « appareil neuf ».

|

Statut |

Condition |

Remarque |

|

Immédiatement disponible |

Occasion |

L’article a été déjà entièrement vérifié et peut être envoyé directement à vous. |

| En stock |

Occasion |

L'article est en notre stock, mais doit être vérifié avant la livraison par nos techniciens Vous recevez des articles entièrement fonctionnels. |

|

Publié |

Occasion |

L’article est toujours au l’offreur. Nous achetons, vérifions et en fin livrons l’article après votre commande. Le certificat de fonctionnement ainsi que le rapport de service sont inclus à la livraison. |

|

Appareil neuf |

Neuf |

C’est un dispositif neuf. L’article n’est pas utilisé et neuf d’usine. En ce qui concerne des article neufs, la garantie du fabricant est valable. |

|

Labprocure |

Occasion |

Responsable du contenu de l‘offre d’appareil est la société Labprocure GmbH, comme annonceur. Labprocure assume la responsabilité des offres annoncées ici ainsi que des photos et des textes d’offre inclus. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

Nachfolgende Abbildungen und Beschreibungen sind modellbezogen und aus Prospekten entnommen.

Sie geben nicht den Lieferumfang des Systems wieder.

Den exakten Lieferumfang entnehmen Sie bitte aus dem Angebotstext.

EINSATZBEREICH

Der Labor - Muffel- / Kammerofen ist ein Laborgerät für wärmetechnische Anwendungen:

Ofenraumvolumen 4,7 1 (M 104) bzw. 3,81 (K 114)

Wärmebehandlung von Proben / Gütern zwischen 300 °C und 1000 °C (M 104) bzw. 1100°C(K114)

Beschickungsgewicht bis zu 5 kg

Das Gerät ist zur Aufstellung und zum Betrieb für in der Regel folgende Bereiche geeignet:

Laboratorien z.B. in Gewerbe, Industrie, Schulen, Universitäten, Krankenhäusern und Biologie

Für Anwendungen zum:

Altern, Analysieren, Anlassen, Aufschließen, Einbrennen, Glühen, Härten, Löten, Oxidieren, Reduzieren, Veraschen und Vorwärmen.

Die Ausrüstung des Ofens mit dem unabhängigen Übertemperaturschutz "Temperatur - Wählbegrenzer" ermöglicht den Betrieb des Gerätes auch ohne ständige Beaufsichtigung.

Das Gerät ist für Dauerbetrieb konzipiert.

Um ungleichmäßige Erwärmung des Beschickungsgutes zu vermeiden, ist darauf zu achten, daß ein Abstand zu den Innenflächen des Ofenraumes eingehalten wird.

Persönliche Schutzausrüstungen, wie Arbeitshandschuhe, Schutzbrille usw., sind wegen der möglichen hohen Arbeitstemperaturen immer vorzusehen.

Das Gerät darf nicht:

- zur Erwärmung von Nahrungsmitteln verwendet werden.

- Für Trocknungen oder Wärmebehandlungen verwendet werden, bei denen brennbare Gase und Dämpfe frei werden, die mit Luft brennen oder ein gefährliches explosionsfähiges Gemisch bilden können. Ebenfalls ist der Ofen nicht zur Wärmebehandlung gefährlicher Stäube und Faserstoffe geeeignet.

GERÄTEBESCHREIBUNG

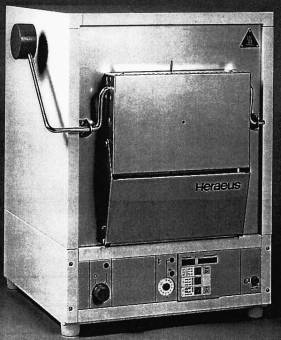

Das Gerät besteht im wesentlichen aus Gehäuse, Ofenraum, Schwenktür und Schalt- und Regeleinheit.

Der Ofenraum des Labor - Muffelofen M 104 wird durch eine keramische Muffel gebildet. Die Heizung ist umlaufend, abgedeckt in die Muffel eingebettet. Der Muffelofen ist für Arbeitstemperaturen bis zu 1000 °C geeignet.

Der Ofenraum des Labor - Kammerofen K 114 wird durch Faserplatten gebildet. Die frei-strahlende Heizung ist in Nuten in den Seiten und der Decke des Ofenraumes eingebracht. Der Boden des Ofenraumes ist mit einer keramischen Platte versehen. Der Kammerofen ist für Arbeitstemperaturen bis zu 1100 °C geeignet.

Die thermische Isolation des Gerätes erfolgt durch Fasermaterialien, die eine gute Wärmedämmung und gute Temperatur - Zeit - Parameter gewähren.

Die Metallfläche um das Ofenmaul wird im Betrieb bei höheren Arbeitstemperaturen heiß, es besteht VERBRENNUNGSGEFAHR. Deshalb ist sie mit dem nebenstehenden Warnzeichen versehen, das vor Berührung dieser Fläche warnt.

Der Ofenraum wird durch eine Schwenktür abgeschlossen.

Die Schwenktür wird über den rechts angeordneten Handgriff betätigt. Beim Öffnen schwenkt die im Betrieb heiße Türinnenseite nach unten. Gleichzeitig wird der integrierte Hitze- und Partikelschutz ausgeklappt. Die Außenfläche der Ofentür dient dann gleichzeitig als Ablage für Beschickungsgüter.

In der Mitte der Schwenktür ist eine Öffnung (0 5 mm) vorgesehen. Hier können Mantel - Thermoelemente, für externe Temperaturerfassungen im Ofenraum, eingebracht werden.

Um den Schutz vor elektrischen Schlag zu gewährleisten, müssen besondere Schutzmaßnahmen zur externen Temperaturerfassung getroffen und beachtet werden - sonst besteht LEBENSGEFAHR und die GEFAHR einer BESCHÄDIGUNG DER ANGESCHLOSSENEN SYSTEME - siehe hierzu die Hinweise im

entsprechenden Abschnitt.

Die Bedienelemente der elektrischen Ausrüstung sind im Bedienfeld der Schalt- und Regeleinheit zusammengefaßt.

Das Gerät ist mit einer festen Anschlußleitung als Steckergerät konzipiert. Der Schutz gegen elektrischen Schlag erfolgt über den Schutzleiteranschluß (Schutzklasse 1).

Der Labor - Ofen ist mit einer Funk-Entstörung ausgerüstet.

Die Temperaturregelung erfolgt durch einen elektronischen Temperaturregler mit Fühlerbrucherkennung, die interne Temperaturerfassung über ein NiCr-Ni - Thermoelement. Die Leistungszufuhr der Heizung wird über ein Leistungs - Halbleiter vom Temperaturregler gesteuert.

SICHERHEITSANFORDERUNGEN

Das Gerät erfüllt die Sicherheitsanforderungen der :

DIN 12 880 Teil 1 / 11.78

DIN VDE 0700 Teil 1 / 04.88

DIN VDE 0875 Teil 11 / 07.92

Darüber hinaus ist der Labor - Muffel- / Kammerofen M104 / K 114 durch das VDE Prüf- und Zertifizierungsinstitut sicherheitstechnisch geprüft. Für das Gerät bestehen, in der geprüften Ausführung (Anhang), die GS - und Funkschutz - Zeichengenehmigungen.

TECHNISCHE DATEN

MECHANISCH:

Abmessungen (B x H x T)

Gehäuse: 456 x 646 x 570 mm

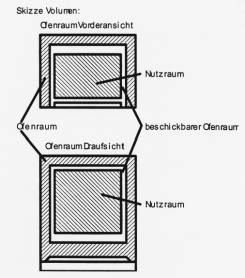

Ofenraum (abzgl. Türisolation): 170 x 130 x 215 mm

Beschickbarer Ofenraum: 130 x 110 x 205 mm

Nutzraum (DIN 17 052 Klasse C,

beheizte Tiefe 160 mm) 130 x 80 x 120 mm

Bodenplatte (B x H x T): 145 x 10 x 240 mm

Mindest - Wandabstände des Ofens

zu angrenzenden Flächen

links: 25 mm

rechts: 100 mm

oben: 300 mm

hinten, mit Abstandhalter: 80 mm

hinten, mit Kamin: 100 mm

hinten, mit Abzuggebläse: 190 mm

Volumen

Ofenraum: 4,7 l

Beschickbarer Ofenraum: 2,9 l

Nutzraum (DIN 17 052 Klasse C,

beheizte Tiefe 160 mm): 1,2 l

Gewichte

Gerät: ca. 52kg

Maximale Beschickungsmenge: 5 kg

THERMISCH:

Arbeitstemperaturen : 300 ... 1000 °C

Temperaturabweichungen

zeitlich (DIN 12 880 Teil 2)

ohne / mit

Kamin: < ± 1 K

mit Abzuggebläse:

< ± 2 K

räumlich

(DIN 17 052 Klasse C)

bei 500 °C: ± 12,5 K

800 °C: ± 7,0 K

1000/1100 °C: ± 7,5 K

Anheizzeiten (ohne Beschickung)

ohne / mit Kamin

auf 500 °C: ca. 80 min

auf 800 °C: ca. 90 min

auf 1000/1100 °C: ca. 120 min

mit Abzuggebläse

auf 500 °C: ca. 50 min

auf 800 °C: ca. 85 min

auf 1000 °C: ca. 160 min

Abkühlzeiten (ohne Beschickung auf 100 °C)

ohne / mit Kamin

von 500 °C: ca. 540 min

von 800 °C:

ca. 670 min

von 1000/1100 °C:

ca. 730 min

mit Abzuggebläse

von 500 °C: ca. 255 min

von 800 °C: ca. 325 min

von 1000 °C:

ca. 350 min

Wärmeabgabe an die Umgebung

bei 500 °C: 0,4 kW

bei 800 °C: 0,8 kW

bei 1000/1100 °C: 1,1 kW

LÜFTUNG / ABGASE:

Luftwechsel im Ofenraum

ohne / mit Kamin

bei 500 °C: ca. 15 h -1

bei 800 °C: ca. 10 h -1

bei 1000/1100 °C: ca. 8 h -1

mit Abzuggebläse

bei 500 °C: ca. 500 h -1

bei 800 °C: ca. 345 h -1

bei 1000 °C: ca. 340 h -1

Abgasstrom (ohne Beschickung)

ohne / mit Kamin

bei 500 °C: 70 l/h

bei 800 °C: 47 l/h

bei 1000/1100 °C: 38 l/h

mit Abzuggebläse 46 m 3 /h

Stutzendurchmesser Kamin / Abzuggebläse:

35 / 52 mm

Abgastemperatur am Stutzen (bei max.

Arbeitstemperatur)

ohne / mit Kamin: 80 (330 1 ) )

mit Abzuggebläse: 110 (200 1 ) )

1)bei Schließen der Tür qilt kurzzeitig der höhere Wert

GERÄUSCH:

Geräuschpegel (DIN 45 635): < 58 dB(A)

ELEKTRISCH:

Nennspannung (± 10 %°): 1/PE AC, 230 V

Nennsfrequenz: 50/60 Hz

Leistungsaufnahme: 2,5 kW

Anschlußwert: 2,6 kVA

Stromaufnahme: 11,4 A

Schutzmaßnahme - Schutzklasse: I

Schutzart: IP 20

Absicherung:

(zum Anschluß an das Versorgungsnetz sind die Regeln der Elektrotechnik und die Technischen Anschlußbestimmungen der EVUs zu beachten)

Schmelzsicherung T 16 A oder Leitungsschutzschalter B 16, Anschluß über Fehlerstrom-Schutzschalter (Auslösestrom ≤ 30 mA) wird empfohlen.

VERWENDETE WERKSTOFFE

Gehäuse Stahlblech verzinkt, lackiert RAL 9002

Ofenraum Keramik C 530 nach DIN VDE 0335

Türisolation Feuerleichtstein (Schamotte)

Ofenmaul Feuerleichtstein (Schamotte)

Thermische Isolation des

Ofenraumes Aluminiumsilikatfaser 1 )

Bodenplatte Feuerleichtstein (Schamotte)

Ofenschale Hitzebeständiger Stahl

Heizleiter Cr Al Fe

Bedienfeld Gemisch aus ABS und PC

Elektrik diverse mit Kunststoffen umhüllte Bauteile, zum Teil auf

epoxydharz- gebundenen, glasfaserverstärkten Leiterplatten bestückt

1) Je nach national gültigen Vorschriften können Faserstoffe für Isolationen als gesundheitsgefährdend eingestuft sein. Im normalen Betrieb ist das Risiko durch freigesetzte Faserstoffe unbedenklich. Bei Reparaturarbeiten oder mechanischer Zerstörung kann es, bei unsachgemäßer Handhabung, zu höheren Freisetzungsraten kommen.