Brabender PL-2100

| Objektnummer | B00018527 |

|---|---|

| Numéro d'identification | 018527 |

| Nom de l'objet | Brabender PL-2100 |

| Statut | Stock unit |

Groupe de produits: Process engineering / Plants

Statut, conditions de livraison et de paiement

Vérification des appareils

Les appareils d’occasion sont vérifiés par Labexchange Service GmbH avant la livraison. Vous recevez des appareils entièrement fonctionnels.

Délai d'expédition

Les délais de livraison indiqués sont les plus rapides pour l’article en cause. Les délais de fait peuvent varier au cas par cas. Les délais de livraison définitifs sont indiqués dans la confirmation de commande.

Nous offrons des livraisons collectives par principe. Le délai de livraison s’oriente à l’article avec le délai de livraison le plus long. Une livraison partielle est possible par prix additionnel.

Méthodes d'expédition

Courrier, agences d'expédition, autocueillette, livraison par flotte de Labexchange

Conditions de livraison

Prix plus frais d’expédition. Les frais d’expédition indiqués sont à prévoir. Dérogations éventuelles sont possibles.

Si les coûts de transport ne sont pas spécifiés, s'il vous plaît demander séparément les frais de transport. Les frais de transport et d'emballage indiqués se réfèrent à l'itinéraire de transport le moins cher et sont sujets à des augmentations de coûts imprévues. En raison d'événements imprévisibles, les tarifs de transport et les délais de livraison peuvent changer à tout moment et doivent être adaptés à la situation actuelle. Incoterm codage selon les Incoterms 2010: Pour personnes qui viennent chercher les dispositifs elles-mêmes: EXW, pour les expéditions par voie maritime: CFR, par avion: CPT, d'autres expéditions: DAP. Remarque: Nous n'établissons pas des preuves préférentielles/EUR1. Dans le cas d’un enlèvement par vos soins/EXW de pays à l’intérieur ou à l’extérieur de la Union européenne, nous devons conserver 16% de TVA d’acheteur comme dépôt de garantie, jusqu’à ce que nous ayons reçu l’attestation de reception/la prevue de livraison.

Modalités de paiement

Nous n’acceptons pas le paiement par lettre de credit, PayPal, etc. Dans tous les cas le montant est payable sans déduction. Jusqu’au paiement complèt l’équipement reste notre propriété. Un escompte n’est pas accordé.

|

Pays |

Modalités de paiement possible |

Remarque |

|

DE, AT, CH |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

NL, BE, LU |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

Autre pays |

Prépaiement, par carte de credit |

|

Nos conditions de vente, de livraison et de paiement sont en vigueur. Vous pouvez télécharger les documents ici.

La vente intermédiaire nous est réservée.

Défintion des statuts

Tous articles sont d’occasion, sauf si explicitement défini comme « appareil neuf ».

|

Statut |

Condition |

Remarque |

|

Immédiatement disponible |

Occasion |

L’article a été déjà entièrement vérifié et peut être envoyé directement à vous. |

| En stock |

Occasion |

L'article est en notre stock, mais doit être vérifié avant la livraison par nos techniciens Vous recevez des articles entièrement fonctionnels. |

|

Publié |

Occasion |

L’article est toujours au l’offreur. Nous achetons, vérifions et en fin livrons l’article après votre commande. Le certificat de fonctionnement ainsi que le rapport de service sont inclus à la livraison. |

|

Appareil neuf |

Neuf |

C’est un dispositif neuf. L’article n’est pas utilisé et neuf d’usine. En ce qui concerne des article neufs, la garantie du fabricant est valable. |

|

Labprocure |

Occasion |

Responsable du contenu de l‘offre d’appareil est la société Labprocure GmbH, comme annonceur. Labprocure assume la responsabilité des offres annoncées ici ainsi que des photos et des textes d’offre inclus. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

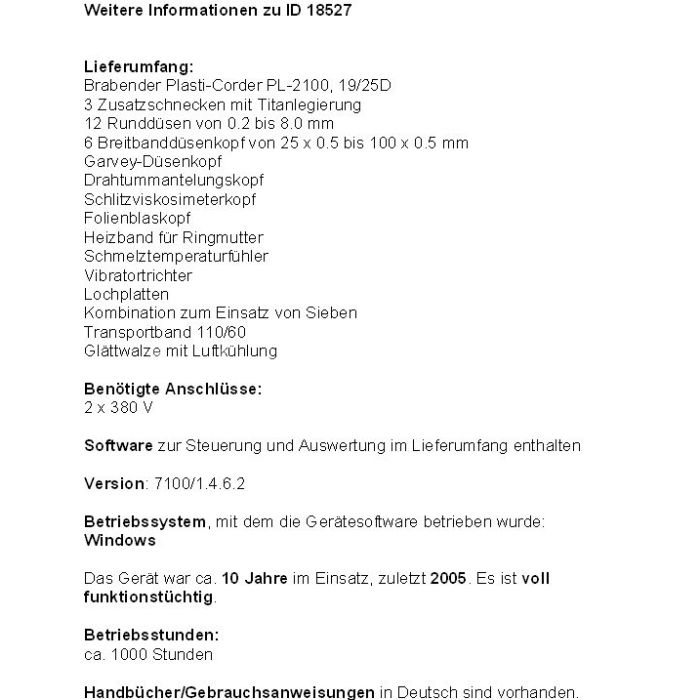

manufacturer : Brabender

model : PL-2100

annotation : Dokumente engl .

The BRABENDER® Torque Rheometers :

PLASTOGRAPH® and PLASTI-CORDER®

BRABENDER® PLASTOGRAPH and PLASTI-CORDER® are torque rheometers with registration and/or monitor display and automatic evaluation of the measuring results including colour printout. They are easy-to-handle high-precision measuring instruments for thermoplastics, thermosets , elastomers , and many other plastic and plastifiable materials. Minimum sample volumes can be examined in practice-oriented tests for their quality and processibility in order to find out the Optimum processing conditions for the respective material. Quality assurance measurements with a large variety of materials can also be run continuously, e.g. parallel to the production process. The DATA PROCESSING PLASTI-CORDER® evaluates the measuring results fully automatically. The electronic PLASTI-CORDER® with analog data registration can be ulteriorly equipped with a computer as well.

Modular System

The measuring instruments are designed according to the modular system and can easily be adapted to the individual requirements of the user. Numerous measuring heads such as measuring mixers, measuring extruders, etc. can be interchanged within very short time. A PLASTOGRAPH® or a PLASTI-CORDER® with various measuring heads thus permits to run many different tests which, either an their own or in combination with other measurements, supply reliable data and permit a sound evaluation of the sample material. Therefore, the BRABENDER® PLASTOGRAPH®and PLASTI-CORDER® are a valuable help not only for experts in production but also for scientists in research and development.

Practice-Oriented Test Conditions

The Parameters influencing the viscosity of a material, such as temperature of the measuring heads and/or shear rate can be varied within a wide range. lt is, thus, possible to create test conditions corresponding exactly to those occurring in large-scale mixers, moulding presses, calenders , extruders, and screw injection moulding machines. When the influence of the test conditions onto the sample material is known, adjustment of the processing conditions at the production machines is no longer a problem.

Measuring Principle

In plastics and rubber industry, numerous test methods are known for determining the viscosity and the processibility of polymers, e.g. by means of parameters determined statically such as the K-value. Very often, however, these methods are based upon test conditions that are far away from practice. In contrast to that, PLASTOGRAPH® and PLASTI-CORDER® use a practice-oriented, dynamic test method. The measuring principle is based an making visible the resistance opposed by the sample material to the rotating blades, rotors, screws, etc. in the measuring mixer or in the measuring extruder. The corresponding torque moves a dynamometer out of its zero position. In accordance with the existing test specifications, a typical PLASTOG RAM (torque versus time diagram), showing also the stock temperature curve, is recorded for each sample material. Thus, the direct relationship between viscosity and stock temperature can be seen. The measuring results can be evaluated rheologically with regard to the apparent viscosity of the sample material.

Raw Material Quality Assurance for Recipe Development

If the test conditions set at the PLASTOGRAPH® or PLASTICORDER® are kept constant, the PLASTOGRAMS clearly show the influence of recipe modifications onto the processibility of the material. In other words, the influence of e.g. stabilizers, plasticizers, lubricants, fillers, catalysts, and pigments can be determined.

The PLASTOGRAPH® and PLASTI-CORDER® are best suited for checking the quality of incoming raw material and for continuous quality assurance measurements in mixing departments where samples of each new batch are tested and compared to standard PLASTOGRAMS of proven material. The user-optimized BRABENDER® software offers numerous advantages: not only are the tests evaluated fully-automatically, but several tests or different parts of one or more tests can be correlated. Furthermore, the software supports the definition of MASTERCURVES serving as a reference for given quality standards. The user can, thus, determine immediately during the subsequent test or any time later whether e.g. a compound meets certain requirements or not.

Testing the Processibility

Formerly, the BRABENDER® torque rheometers were applied primarily as viscometers in a narrower sense for measuring the viscosity of polymer melts. There is no doubt that the melt viscosity of homogeneous, non-Newtonian compounds represents an important parameter when such melts are subjected to dynamic shearing. However, melt viscosity measurements using only a single measuring head do not completely define the " processibility " of a material. For this reason, the program of interchangeable measuring heads for the BRABENDER° PLASTOGRAPH®and PLASTI-CORDER® has been extended continuously. By means of tests with measuring mixers, planetary mixer, and measuring extruders with many different die heads, special processing steps occurring in production machines can be simulated in order to determine further material characteristics that are relevant for the production process.

Special measuring mixers are available for determining the Fusion and plastification behaviour of PVC compounds. These tests supply reliable data e.g. about the influence of the different material components on the transformation of the granules or powder into a homogeneous melt which is of utmost importance for the extrusion process. Other measuring mixers serve for studying the melt viscosity and the heat and shear stability, i.e. the variation of the viscosity of the polymer as a function of the combined influence of temperature and shear due to chemical and/or physical changes in the materials tested.

With a PLANETARY MIXER, the particle structure of PVC powders is determined by measuring the plasticizer absorption and the pourability of the compounds.

lt is reasonable to complete the tests with measuring mixers by laboratory extruder tests. Different types of extruders developed for various applications and numerous die heads are available for determining the extrudability of polymers. The viscosity and the flow of the melt through different dies is observed, and the extrudate is checked for melt fracture, swelling, gloss, gels, pigment dispersion, etc. By ejecting the extruder screw at the end of the test, the melt spiral on the screw gives a picture of the processing conditions along the screw. Equipped with one of the manifold capillary die heads, the extruder can be used as a capillary viscometer in production control and in research and development for simultaneously measuring the melt pressure and the melt temperature in the extruder as well as the output per unit of time.

Each of the individual measuring methods covers certain criteria of the processibility which are based an different parameters. The shape and the size of the individual particles of PVC dry blends which determine the flowability of the compound loose their influence as soon as the material has been transformed into a homogeneous melt. While the melt viscosity of a polymer results from the combination of different factors such as e.g. the molecular weight of the polymer and of other components like lubricants, stabilizers, etc., the flow of the melt through a die may be influenced by some additional factors, too, such as the elastic deformation of the melt, the wall adhesion within the die channels, segregation of individual components in the extruder or in the die head as it can be observed with some titanium dioxides, swelling of the extrudate after leaving the die, etc.

Using a large variety of measuring methods, the BRABENDER° PLASTOGRAPH® and PLASTI-CORDER® permit to completely describe the processibility of a material. The measuring instruments are continuously improved, and new types are developed in order to always meet the state of the art and to comply with special requirements of our customers.