Varian 8200 CX

| Objektnummer | B00017758 |

|---|---|

| Numéro d'identification | 017758 |

| Nom de l'objet | Varian 8200 CX |

| Statut | Stock unit |

Groupe de produits: CLHP passeurs d'échantillons

Statut, conditions de livraison et de paiement

Vérification des appareils

Les appareils d’occasion sont vérifiés par Labexchange Service GmbH avant la livraison. Vous recevez des appareils entièrement fonctionnels.

Délai d'expédition

Les délais de livraison indiqués sont les plus rapides pour l’article en cause. Les délais de fait peuvent varier au cas par cas. Les délais de livraison définitifs sont indiqués dans la confirmation de commande.

Nous offrons des livraisons collectives par principe. Le délai de livraison s’oriente à l’article avec le délai de livraison le plus long. Une livraison partielle est possible par prix additionnel.

Méthodes d'expédition

Courrier, agences d'expédition, autocueillette, livraison par flotte de Labexchange

Conditions de livraison

Prix plus frais d’expédition. Les frais d’expédition indiqués sont à prévoir. Dérogations éventuelles sont possibles.

Si les coûts de transport ne sont pas spécifiés, s'il vous plaît demander séparément les frais de transport. Les frais de transport et d'emballage indiqués se réfèrent à l'itinéraire de transport le moins cher et sont sujets à des augmentations de coûts imprévues. En raison d'événements imprévisibles, les tarifs de transport et les délais de livraison peuvent changer à tout moment et doivent être adaptés à la situation actuelle. Incoterm codage selon les Incoterms 2010: Pour personnes qui viennent chercher les dispositifs elles-mêmes: EXW, pour les expéditions par voie maritime: CFR, par avion: CPT, d'autres expéditions: DAP. Remarque: Nous n'établissons pas des preuves préférentielles/EUR1. Dans le cas d’un enlèvement par vos soins/EXW de pays à l’intérieur ou à l’extérieur de la Union européenne, nous devons conserver 16% de TVA d’acheteur comme dépôt de garantie, jusqu’à ce que nous ayons reçu l’attestation de reception/la prevue de livraison.

Modalités de paiement

Nous n’acceptons pas le paiement par lettre de credit, PayPal, etc. Dans tous les cas le montant est payable sans déduction. Jusqu’au paiement complèt l’équipement reste notre propriété. Un escompte n’est pas accordé.

|

Pays |

Modalités de paiement possible |

Remarque |

|

DE, AT, CH |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

NL, BE, LU |

Paiement par facture, prépaiement, par carte de credit |

Paiement par facture est possible pour clients professionnels. |

|

Autre pays |

Prépaiement, par carte de credit |

|

Nos conditions de vente, de livraison et de paiement sont en vigueur. Vous pouvez télécharger les documents ici.

La vente intermédiaire nous est réservée.

Défintion des statuts

Tous articles sont d’occasion, sauf si explicitement défini comme « appareil neuf ».

|

Statut |

Condition |

Remarque |

|

Immédiatement disponible |

Occasion |

L’article a été déjà entièrement vérifié et peut être envoyé directement à vous. |

| En stock |

Occasion |

L'article est en notre stock, mais doit être vérifié avant la livraison par nos techniciens Vous recevez des articles entièrement fonctionnels. |

|

Publié |

Occasion |

L’article est toujours au l’offreur. Nous achetons, vérifions et en fin livrons l’article après votre commande. Le certificat de fonctionnement ainsi que le rapport de service sont inclus à la livraison. |

|

Appareil neuf |

Neuf |

C’est un dispositif neuf. L’article n’est pas utilisé et neuf d’usine. En ce qui concerne des article neufs, la garantie du fabricant est valable. |

|

Labprocure |

Occasion |

Responsable du contenu de l‘offre d’appareil est la société Labprocure GmbH, comme annonceur. Labprocure assume la responsabilité des offres annoncées ici ainsi que des photos et des textes d’offre inclus. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

Firma: Varian

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

Introduction

The 8200 CX AutoSampler mounts over the injectors on the top cover of the Varian Series 3000 Gas Chromatographs (with the exception of the 3300). The 8200 CX AutoSampler is operated through the keypad on the front panel of the GC.

The AutoSampler is not powered through the GC but through a "power entry module" located on the rear panel of the Pneumatics Module. The main power switch, fuse(s) and voltage selection components are also located on this rear panel. The AutoSampler can be operated at 100, 120, 220, and 240 Volts, 50/60 Hz, single phase, or Split phase (phase/phase) power. For the procedure to select the appropriate voltage for the 8200 CX AutoSampler, see Section 2, paragraph 2.7 of this manual. For the procedure to change fuses, see Section 6, paragraph 6.6 of this manual.

In Order for the 8200 CX AutoSampler to operate with the 3000 Series GC, the GC must be equipped with the most recent version of the 8200 CX IBDH/CPU PC Board (see paragraph 2.3.1, Section 2).

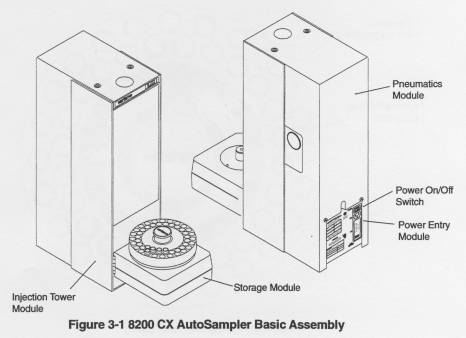

The 8200 CX AutoSampler is constructed of three modules: Storage Module, Injection Tower Module, and Pneumatics Module. Refer to Figure 3-1.

Storage Module

The Storage Module consists of: 48-vial carrousel, turntable, Position Sensor Board, vial sensors, and two synchronous motors that rotate the turntable and move it in and out of the sampling position. The Storage Module is hinged to the Injection Tower and mounts left-hand (standard), or right-hand (optional for the Star 3600 CX GC).

A power ON indicator (LED) is located on the front right side of the Storage Module. This LED lights when the power cord is properly connected and the power switch of the AutoSampler is turned ON.

Carrousel (Vial Racks)

The carrousel is constructed of a chemically resistant polymer 5-3/4" diameter x 1-1/4" deep and can hold up to forty-eight 2 mL vials. A Center knob allows you to easily lift and reposition the turntable. A small raised indicator marks the Home vial position.

The carrousel is divided into four sections (racks) of 12 vial positions. There are four rack numbers: 1, 2, 3, and 4. The 8200 CX AutoSampler can be operated in rack automation (with separate GC methods for each rack) as well as sequence automation. All samples in the carrousel are sampled sequentially. Random sampling is not possible uniess the 8200 CX AutoSampler is controlled through the GC Star Workstation.

The carrousel label designates the location of the four virtual racks, as well as the location of the Home position (Rack 1, Vial 1). Position the label on the carrousel using the keyed Gutout. See Figure 3-2. The carrousel label uses a semi-permanent adhesive that permits the label to be easily removed and replaced. Refer to Appendix C when you need to Order additional labels.

Solenoid Valves Assignments

The five solenoid valves in the pneumatics module are assigned (see Figure 3-6) as:

Ll Controls solvent flow from Reservoir B to the syringe side arm.

L2 Controls solvent flow from Reservoir A to the syringe side arm.

L3 Pressures Solvent Reservoir A.

L5 Pressures Solvent Reservoir B.

L7 Actuates the walte arm assembly (aligned with the needie).

Power Entry Module

The Power Entry Module is located on the lower rear panel of the Pneumatics Module and includes: main power switch; main power cord receptacle; fuse(s); and, voltage selection card. Before connecting to the AutoSampler to power, check the voltage selection (paragraph 2.7 in Section 2) to be sure that the white pin is in the hole that matches the voltage rating stamped on the serial number labet. Instructions for changing the fuse(s) are found in Section 6, paragraph 6.6.

8200 CX Controller PC Board

The 8200 CX Controller PC Board, including the Power Supply circuit, is mounted on the rear wall of the Pneumatics Module. To access the 8200 CX Controller PC Board, remove the Pneumatics Module cover. Electrical leads to the five solenoid valves, and the syringe carriage stop solenoid (L4) connect at J8 on the 8200 CX Controller PC Board. The leads from each solenoid terminate in a two-pin connector. Plug each valve connector into a specific location at J8. See Figure 3-7. DO NOT remove the tie wrap from the connectors plugged into J8.

Injection Tower Module

The Injection Tower Module houses the syringe carriage and syringe mounting hardware, syringe carriage drive stepper motor, waste cup, and syringe plunger stepping motor drive assembly. The Injection Module, complete with the hinged Storage Module, bolts to the Pneumatics Module.

Syringe carriage

The syringe carriage is moved through vial sampling, injecting, and washing positions by a stepping motor and timing belt. See Figure 3-8.

At the end of a run, the syringe carriage returns to the "Horne" position. If power is turned off or there is a power failure, the stop solenoid opens and the carriage drops to its rest position an the stop latch. When the power is restored, the stop solenoid pulls in and the carriage returns to its operating "Horne" position.

NOTE. When aligning the 8200 CX AutoSampler syringe, the power must be ON to both the GC and the AutoSampler.

Syringe Needle Assembly

The syringe/needie assembly (P/N 03-918986-00) includes: 10 gL syringe with a side inlet fitting; plunger guide; and, non-coring side hole needie (P/N 03-918987-00). See Figure 3-9.

Waste Arm/Cup Assembly

The waste arm is electrically driven to the "out" position by an electrical solenoid and is spring returned to the In" position. The waste arm positions the cup under the needle during washing or flushing cycles, and in the retracted position during sample injection.

When it becomes necessary to change the waste cup seal (septum), replace only with P/N 00-997628-00. A supply of these seals is included in the Standard Accessory Kit. Install the new seal with the Teflon@ coated surface down. See Figure 3-10.

There is no fixed schedule for changing the waste cup seal. Repetitive plugging of the needle may indicate the need to change the seal.

Vial Retainer Arm

The vial retainer arm is a metal bar clamped in a plastic holder that is positioned just above the hole in the sample vial cap. The retainer prevents the vial from lifting from the carrousel when the needle is withdrawn from the vial. During injection the retainer is moved out of the syringe carriage path by the syringe carriage as it descends. When the syringe carriage moves up from the inject position the retainer returns to its normal position over the vial. Figure 3-11 shows the retainer in its correct position.

The vial retainer arm is adjusted at the factory to align with the syringe needle guide. If the vial retainer arm is out of position, the arm Gould either interfere with the Operation of the needle guide, or fail to hold the vial in the carrousel during the withdrawal of the syringe needle.

Adjustments to the vial retainer arm should be performed by a Varian Customer Support Representative.

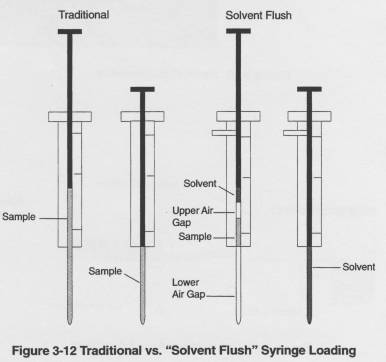

Solvent Flush Injection (Standard Mode)

The 8200 CX AutoSampler (in the standard mode) uses an automated "solvent flush" sample injection technique. This injection mode brackets the sample between two air gaps followed by a solvent plug that sweeps the sample from the syringe and needle.

Once you haue entered the sample and solvent plug volumes, the syringe is loaded automatically. The upper and lower air gap volumes are fixed at 0.5 and 0.8 microliters, respectively. The solvent plug that follows the sample ensures that the entire sample is flushed out of the syringe and needle and that the needle is filled with solvent.

Comparative studies show that the automated solvent flush injection technique, whether the sample is injected into hot, cold, split, or splitless injectors, result in consistently lower %RSD values than the traditional sample injection technique.

To set values for the solvent flush method, refer to Section 4, Operation, of this manual.

Typical Sampling and Injection Sequence

The typical sampling and injection sequence of the 8200 CX AutoSampler, proceeds as follows:

1. The solvent plug is sized. The syringe plunger fully retracts past the side arm inlet of the syringe barrel. The waste cup moves under the syringe, the syringe drives down to insert the needle into the waste cup.

2. Either Reservoir A or Reservoir B is pressurized. Solvent moves through the syringe barrel and needle. This solvent may or may not be identical to the sample solvent.

3. The syringe plunger moves downward while the reservoir is pressurized. The plunger stups before it reaches the bottom of the barrel, leaving a predetermined amount of solvent in the syringe (the solvent flush plug).

4. The needle withdraws from the waste cup. Immediately the syringe plunger withdraws slightly to create an upper air gap of predetermined size (0.5 gL). The waste cup withdraws from the syringe path.

5. The carrousel moves to its position under the syringe, and rotates until the selected sampie vial is below the syringe needle.

6. The syringe carriage moves down until the syringe needle pierces the sample vial septum and entern the sample.

7. The syringe plunger moves up and withdraws from the sample vial a predetermined amount of sampie into the syringe at a predetermined uptake rate. The plunger pausen in the high position for a predetermined time before the syringe carriage moves up and the needle withdraws from the vial.

8. The syringe plunger moves up 0.8 gL to introduce a lower air gap below the sample plug.

9. The sample carrousel moves to the forward position and out of the syringe path. The syringe carriage moves down and the needle pierces the GC injector septum. The syringe plunger moves down injecting the sample and a portion of the solvent plug leaving the remainder of the solvent in the needle.

10. The syringe carriage moves to its top position; the waste cup moves into position below the needle. The syringe carriage moves down and the needle inserts in the waste cup. The syringe plunger moves up and clears the side arm port. Solvent A or solvent B flushes through the syringe for a predetermined wash cycle. At the completion of the wash cycle, the next loading and injection sequence beginn (if in multiple injection mode) or waits for a manual start (if in single injection mode).

For a comparison of traditional syringe loading and "solvent flush" syringe loading

techniques, see Figure 3-12.

Optional Injection Moden

For descriptions of injection modes other than the standard mode, refer to paragraph 4.6, Section 4. If solvent contamination is a particular concern, as in the case of undiluted or pure samples, use the Neat injection mode. To operate the 8200 CX AutoSampler in the Neat mode, see paragraph 4.6, Section 4.