manufacturer

:

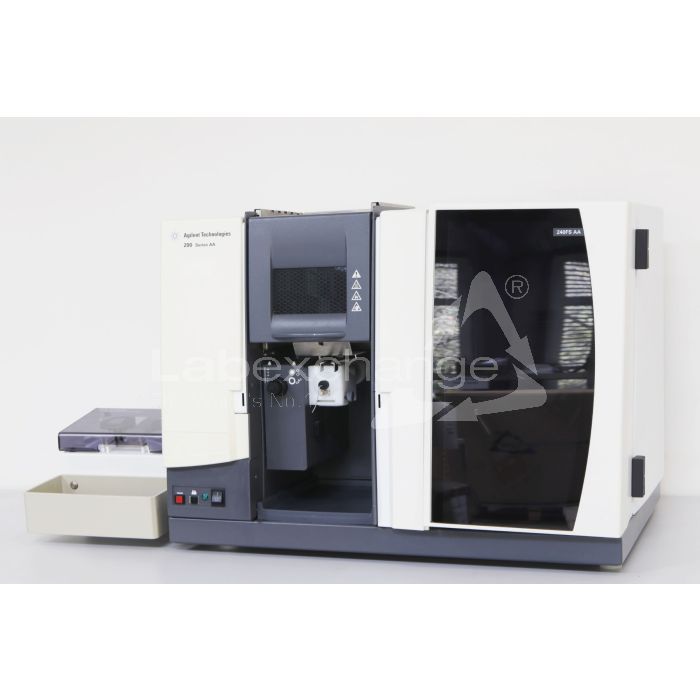

Varian

model

:

AAS 240 FS

annotation

:

Dokumente

engl

.

AA240FS

Features

-

Fast Sequential capability

-

Full automation

-

PC control

-

Deuterium background operation

-

True double beam optics

Fully automated PC-controlled true double-beam Atomic Absorption spectrometer with Fast Sequential operation for fast multi-element flame AA determinations.

Features 4 lamp positions and automatic lamp selection.

Supplied with

SpectrAA

Base and PRO software versions.

Flame AA Hardware

Features

Optics

Narrow beam optics match flame and furnace profiles.

Fully sealed optics feature quartz-

overcoated

mirrors for enhanced protection.

The AA240 FS feature a Rotating Beam Combiner, which alternately passes the sample or reference beam into the monochromator for maximum light transmission.

Wavelength range

185-900 nm

Optical bench

Optics mounted on a reinforced flat plate with a fitted deep-drawn cover for protection from dust and vapor.

Monochromator

Automated self-calibrating Czerny-Turner monochromator with microstepping driver for enhanced resolution. PC-controlled wavelength selection and peaking.

Focal length

250 mm

Wavelength repeatability

±0.04 nm

Wavelength slew rate

2000 nm/min.

Grating

Holographic diffraction grating with 1200 lines/mm blazed at 240 nm.

Dispersion 3.1-2.3 nm/mm

Detector

Selected wide range photomultiplier tube for maximum signal to noise performance

Type R955

Slits

Automated slit selection.

Settings: 0.2, 0.5 and 1.0 nm plus reduced height 0.5 nm slit for graphite furnace operation

Lamp support

4 lamps mounted in fixed positions

Fast lamp selection using mirror

Manual or automatic operation

(

automated

lamp selection standard on AA240 FS).

All lamps operated simultaneously in Fast Sequential mode

Accommodates single or multi-element, coded or uncoded lamps.

Compatible with high-intensity UltrAA lamps.

Lamps secured by the base without restraining clips or power cables. Lamps automatically switched off at the end of analysis. Users can elect to leave the lamp on at the end of an autorun. Automated pre-warming of next lamp in sequence.

Optional UltrAA lamp looming available

Background corrector

High-intensity deuterium background corrector covering wavelength range 185-425 nm. Corrects up to 2.5 background absorbance. 2 ms response. Electronic modulation with automatic gain attenuation for improved beam balance. Deuterium lamp easily aligned and replaced by the user.

Internal air purge

Barb fitting provided on rear of spectrometer module to enable connection to a supply of clean, dry air. This enables internal purging of the instrument to maintain a positive flow of clean air through the instrument. This excludes dust and corrosive vapors, enhancing corrosion protection in rigorous conditions

FS operation

Supports Fast Sequential operation, enabling multiple elements to be measured in rapid sequence in a single sample measurement, without the need to re-analyze the samples for subsequent elements.

Requires PRO software (optional on AA240).

Gas control

Hammer programmable gas

control

standard.

Automatic gas control preset oxidant flow and variable fuel flow adjusted using manual flow meter adjustments.

Automatic oxidant change-over.

Hammer programmable gas control PC-controlled gas flows with automatic setting of gas flows for each element. Automatic oxidant changeover. Features unique fast response Hammer solenoid valve for rapid regulation and setting of selected gas flow.

Flame safety system

Separate ignite and flame-off buttons. Eight safety interlocks monitor burner type, burner correctly fitted, liquid trap, pressure relief bung, flame shield, flame operation, mains power, oxidant safety reservoir and deuterium lamp cover. Internal gas connections made automatically without external gas hoses. Separate upper and lower flame shields and a chimney protect against heat and UV radiation from

the

flame

. External adjustment of all burner and spray chamber controls. Violation of any safety interlock

eighter

inhibits flame ignition or extinguishes existing flame.

Burner adjuster

Manual adjustment of burner height.

Flame atomization

Universal Mark 7 atomization system supplied as standard.

Spray chamber

Fluorinated high density polyethylene Mark 7 design suitable for aqueous and organic solutions.

Mixing paddles

Removable twin-headed mixing paddles fitted inside the spray chamber for better mixing and extended operation with high dissolved solids solutions.

Impact bead

Externally adjustable glass impact bead for optimum sensitivity and best precision.

Optional Teflon bead for HF applications

Nebulizer

Adjustable nebulizer with inert platinum/iridium capillary and PEEK venture for corrosion resistance.

Liquid trap

Integral liquid trap with magnetic float interlock.

Burner

Incoloy air/acetylene burner with Teflon corrosion shield. Provides external burner rotation. Optional nitrous-oxide/acetylene burner.

Typical performance

Absorbance > 0.9 with precision of < 0.5 % RSD from ten 5 second integrations for 5 mg/L Cu standard.

Recommended environmental conditions

Instrument storage:

5-45 °C at 20-80 % relative humidity, non condensing.

Instrument operation:

< 853 m, 10-35 °C, 8-80 % relative humidity, non condensing.

853-2133 m, 10-25 °C, 8-80 % relative humidity, non condensing.

Electrical requirements for AA140/240/280

Mains supply 100/120/220/240 VAC ±10%, 230 VAC +14% -6%, 230 VAC +6% -14%

50 or 60 Hz ±1 Hz. Power requirements detailed in following table.

Gas requirements for flame operation

Air supply

Clean, dry and oil-free at pressure of 245-455 kPa (35-65 psi).

Recommended pressure 350 kPa (50 psi).

Typical consumption 13.5-20 L/min.

Acetylene supply

Instrument grade (99.0% pure) packaged in acetone at pressure of 65-100 kPa (9.5-14.5 psi). Recommended pressure 75 kPa (11 psi).

Typical consumption 1.5-8.0 L/min.

Nitrous oxide

Instrument grade (99.5% pure) at pressure of 245-455 kPa (35-65 psi). Recommended pressure 350 kPa (50 psi). Typical consumption 11-16 L/min.

Fume extraction

Spectrometer must be located under an extraction system providing flow of at least 6 cubic metres/min (200 cfm) at 16 mm water gauge static pressure. Exhaust must be ducted to an external vent.

Electrical requirements for AA240/280 Zeeman and GTA120/GTA-110

208-240 VAC ±10%, 50 or 60 Hz ±1 Hz. Rated current 15 A single phase.

Surge current of up to 40 A for approx. 1 sec. reducing to 20 A for up to 10 sec. in any 1 or 2 minute period. Power requirements detailed in following table.

Cooling water requirements for GTA120/GTA-110

Mains supply or recirculated (preferred) with flow rate of 1.5-2 L/min at 175-210 kPa (25-30 psi).

Maximum pressure 210 kPa (30 psi). Recommended temperature range 18-25 °C (65-78 °F).

Maximum permissible temperature 40 °C (104 °F).

Gas requirements for GTA120/GTA-110

Argon or nitrogen (dry 99.99% argon preferred) at pressure of 140-200 kPa (20-29 psi).

Recommended pressure 140 kPa (20 psi). Maximum consumption 3.8 L/min (3.1 L/min. for GTA-110).

Gas requirements for VGA-77

Argon or nitrogen (dry 99.99% argon preferred) at pressure of 300-400 kPa (42-57 psi).

Recommended pressure 300 kPa (42 psi).

Maximum consumption 0.1 L/min.

Weights, dimensions and power requirements

AA140/240/240 FS

Weights

Unpacked

kgs

(lbs)

56 (123)

Packed

kgs

(lbs)

97 (214)

Dimensions

Unpaced

(W x D x H) cm (inches)

79 x 58 x 59 (31 x 23 x 23)

Power Consumption VA

170