Zymark Turbo VAP 96

| Objektnummer | B00019653 |

|---|---|

| ID-number | 019653 |

| Object name | Zymark Turbo VAP 96 |

| Status | Stock unit |

Product group: Rotation evaporators / Distillation

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

Introduction

The Zymark TurboVap LV Evaporator is a microprocessor-controlled evaporator that provides simultaneous, automated concentration of multiple samples, unattended operation, convenience, and speed.

Automated

Microprocessor-control provides monitoring of the timed operation and water bath temperature. It also provides automatic gas shutoff and operational diagnostics.

Convenience

The operator is able to start a run of samples and leave it unattended. When the preset time has expired, the gas shuts Off automatically and the evaporator sounds a buzzer. The buzzer continues to beep every 30 seconds until operation is stopped.

Patented Technology

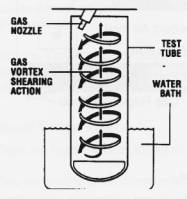

The patented "gas vortex shearing action" speeds evaporation.

Multiple Sample Processing

The evaporator uses one to five manifold rows. Each manifold has ten nozzles that extend into the tubes to supply the gas for evaporation. This allows up to 50 samples to be processed simultaneously. If you have less than 50 samples, you activate only those rows where samples are located.

Flexible

Evaporation may be paused, then stopped or resumed at any time. Time and temperature settings, and the selection of a row of tubes may be changed at any time.

Requires No Hood

The hinged cover and exhaust System save valuable hood space and permit benchtop use.

Complete With Accessories

Most of the hardware needed for installing and using the evaporator is provided. Racks and tubes are ordered separately. There are several rack sizes from which to choose. These include two types of 16 mm x 100 mm racks, two types of micro-centrifuge tube racks, two types of 15 mL conical bottom centrifuge tube racks, and racks for l0mm x 75 mm, 12 mm x 75 mm, 13 mm x 100 mm, 16 mm x 125 mm, 20 mm x 150 mm, and 10 mL conical bottom centrifuge tubes.

Specifications

Capacity: fifty tubes

Containers and Working Volumes: (using different racks)

Containers: Working Volumes

10 x 75 mm tubes up to 4 mL

12 x 75 mm tubes up to 4 mL

13 x 100 mm tubes up to 7 mL

16 x 100 mm tubes up to 12 mL

16 x 125 mm tubes up to 16 mL

20 x 150 mm tubes up to 30 mL

10 mL conical bottom tubes up to 10 mL

15 mL conical bottom tubes

up to 15 mL

15 mL volumetric

conical bottom tubes,

up to 15 mL

(compatible with the AutoTrace SPE Workstation)

1.5 - 2.0 mL micro-centrifuge tubes

(screw cap type)

1.5 to 2 mL

1.5 - 2.0 mL micro-centrifuge tubes

(flip cap type) 1.5 to 2 mL

NOTE: Full sample tubes must be evaporated with care to prevent splashing.

Typical Evaporation:

Rates: Solvent Time (min.)

Ethyl Acetate 17.5

Hexane 9

Methanol 25.5

Methylene Chloride 17

* Conditions:

10 mL of solvent evaporated to dryness at 52 °C. Methylene chloride bath temperature at 38°C.

Gas Consumption:

1 cfm per row of nozzles at 15 psi (from a source capable of supplying 60 to 100 psi.)

Water Bath Temperature Range:

ambient to 90°C

Gas Regulator and Gauge Range:

0 to 30 psi (206.9 KPa)

Dimensions:

Height: 11.9" (30.2 cm)

Width: 21.2" (53.8 cm)

Depth: 11.9" (30.2 cm)

Weight :

40.5 lbs. (18.47 Kg.) empty water bath

Time Range:

1 to 99 min. or 0.1 to 9.9 hrs. can also be set to 00 for infinite time

*** NOT for in vitro testing ***

Theory of Operation - Helical Gas Flow

The evaporator takes advantage of a patented gas vortex shearing action that maintains high evaporation rates regardless of sample height in the tubes. The helical flow sets up a vortexing action that provides for sample homogeneity and continuous rinsing of the tube wall. The vapor-laden gas exits via an unobstructed path up the center portion of the tubes and is removed by an exhaust fan to the exhaust port in the back of the unit. From the exhaust port, the exhaust duct is routed by you to a suitable, outside-vent location.

Main Features

Cover

Operation automatically begins or resumes when the cover is closed. The evaporation pauses when the water bath cover is open. After an evaporation, open the cover to prevent condensation within the unit.

Control Panel

The control panel allows you to control evaporation in one to five rows of 10 tube positions. (Samples are not required in each position.) The microprocessor constantly monitors the control panel allowing you to make changes to the panel settings at any time during the evaporation process. Yellow lights indicate the row(s) of tubes selected. The green light to the right of the START/PAUSE button is on when an evaporation is in progress and blinks when the evaporation has been paused. A STOP button on the control panel allows for termination of the evaporation process. The control panel also has two displays: one indicates time remaining; the other indicates the actual water bath temperature. These displays also provide diagnostic codes when an error is detected.

Automatic Control

The Operator sets the desired evaporation parameters for each run. After pressing the START button and closing the lid, the evaporator automatically monitors the programmed process. A buzzer sounds when the evaporation is completed.

Water Bath

Sample tubes are placed in a rack that sits in a temperature-controlled water bath. The water bath operates over a temperature range of ambient to 900C.

The TurboVap LV evaporator is not designed to cool but the water bath temperature can be brought down as much as 15C0 by using the evaporation as a cooling source. Cooling ability varies with the evaporation rate.

Use the numeric pushwheel to select the desired temperature setting.

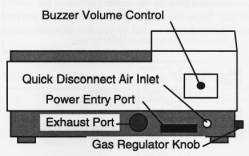

Gas Supply

The evaporator has a gas supply input on the back of the unit. The fitting provided has an internal shutoff which allows you to disconnect the evaporator from the supply without shutting off the gas supply itself.

There is a gas regulator knob on the side of the unit and a gauge on the front panel. Use the gas regulator knob to reduce the external gas supply pressure (60 psi to 100 psi) to the 0 to 30 psi desired helical gas flow directed at each of the sample tubes.

The gas supply is routed through a stainless steel manifold to each sample tube.

Exhaust Port

Solvent vapors are removed by an exhaust fan and routed to the exhaust port on the back of the unit. You must route the venting hose from the exhaust port to a proper ventilation System venting to the outside. The TurboVap LV" s design assures that vapors are contained for you to remove from the laboratory environment.

Once the TurboVap LV is properly installed and properly vented, vapors remain contained and they are removed automatically when the system is operating properly.

Buzzer Volume Control

There is a buzzer with an adjustable volume control in the back of the unit.

Turn the knob in either direction until the desired volume is achieved.

A repeating beep indicates a completed run.

A long beep indicates interrupted operation.

A short beep indicates a recognized key input.