Shimadzu SIL-9A

| Objektnummer | B00008018 |

|---|---|

| ID-number | 008018 |

| Object name | Shimadzu SIL-9A |

| Status | Stock unit |

Product group: HPLC-Autosamplers

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

Firma: Shimadzu

Kommentar: Dokumente für IDNR. 12276

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representating the delivery volume. The exact delivery content you will find only in the offering text.

RID-6A

Specifications

Measuring System: Deflection type

Range of refractive index: 1 to 1.75

Measuring range: 0.25 X 10 -4 to 512 X 10 -6 RIU FS, selectable in 12 steps

Noise level: 2.5 X 10 -9 RIU short term noise for water-sealed and SLOW response conditions; short term noise as defined by ASTM

Linearity: 8 X 10 -4 RIU or higher

Cell volume: 10µl

Material in contact with liquid: SUS316, quartz, Teflon

Response: 3 step selection: FAST, STD and SLOW

Controlled temperature of cell: 35°C (Thermal fuse 70°C)

Zero adjustment: Optical zero adjustment

Automatic zero adjustment

Fine zero adjustment (manual)

Auto zero adjustment range: Maximum of ±4 X 10 -4 RIU

Auto zero adjustment accuracy: Maximum of ±3 X 10 -8 RIU

Recorder: 1mV, 10mV full scale

Integrator terminal output: 0.4V/1 X 10 -4 RIU, 0.1V/1 X 10 -4 RIU

Weight: 13kg

Size: 26(W) X 16(H) X 40(D) cm

Optimum operating temperature range: 10 to 40°C (when temperature is not controlled) Power requirements: RID-6A is classified as follows according to the supply voltage:

P/N 228-16510-91 100V±10V 1A 50, 60Hz

228-16510-92 115V±10V 1A 50, 60Hz

228-16510-93 220V±20V 0.5A 50, 60Hz

228-16510-94 240V±20V 0.5A 50, 60Hz

228-16510-95 230V±20V 0.5A 50, 60Hz

DGU-3A

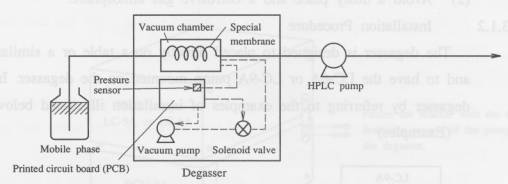

Outline of Degasser

The DGU-3A online degasser continuously removes gases dissolved in liquid through a special plastic membrane.

When the degasser is connected to the HPLC pump, the degasser continuously removes gases dissolved in the mobile phase without changing its composition. Consequently, the degasser improves stability and repeatability in HPLC analysis because it prevents generation of bubbles due to dissolved gases, poor delivering of the pump due to bubbles, noise an the baseline of the detector, and fluctuation of the detector baseline due to the variation of dissolved gas concentration.

The DGU-3A has three independent flow paths and the DGU-4A has two independent flow paths. The degassing characteristic per flow path and other functions are common to both the DGU-3A and DGU- 4A, and the only difference between them is the number of flow paths.

The operating principle of the degasser is illustrated below.

The mobile phase passes through the special plastic membrane mounted in the vacuum chamber of the degasser. Gases dissolved in the liquid selectively pass through the membrane into the space in the vessel because of smaller gas molecular sizes, and higher mobility than the liquid, and the close affinity of gases to the membrane. In the above process, gases are removed from the liquid to the space in the vacuum chamber and are then exhausted out of the system.

Specifications:

Degassing characteristics The concentration of residual dissolved oxygen at the outlet of the degasser is 1.5ppm max. per flow path when air-saturated ion-exchanged water at an ambient temperature of 25°C is passed through the degasser at a flow rate of 3ml/min max.

Maximum flow rate 10ml/min (water)

Internal volume About 15ml per flow path

Operating pressure 2kg/cm 2 max. (Use is limited to the suction side, i.e., inlet, of the pump. Feeding of liquid to the degasser under pressure is not allowed.)

Connecting tubes Teflon tubes of 3mm OD and 2mm ID

Wetted materials Special plastic resistant to all solvents (degassing membrane), Kel-F (connection joints), Teflon (connection tubes)

Other

Self-cleaning When the vacuum pump is started or stopped, the solenoid valve is switched over to draw in ambient air to prolong the service life of the vacuum pump.

Safety feature A device is provided to stop the vacuum pump automatically if the vacuum pump is over-heated.

(Remains in standby to allow natured cooling.)

Dimensions Width 260mm, height 140mm, depth 400mm

(Not including projecting parts)

Weight 13kg

Ambient temperature and humidity: 10 to 40°C and 40 to 85%, respectively

Storage temperature 0 to 60°C (with the flow paths dried)

Power supply: DGU-3A is available in the following modifications according to the power supply voltage.

P/N 228-24200-91 AC100V±10% 100VA 50/60Hz

P/N 228-24200-92 AC115V±10% 100VA 50/60Hz

P/N 228-24200-93 AC220V±10% 100VA 50/60Hz

P/N 228-24200-94 AC240V±10% 100VA 50/60Hz

P/N 228-24200-95 AC230V±10% 100VA 50/60Hz

Detector SPD-6AV

Specifications

Wavelength range 195 to 700nm

Wavelength accuracy ±2nm

Wavelength reproducibility ±0.5nm

Spectral bandwidth 8nm

Light source Deuterium (D 2 ) lamp (195370nm)

Tungsten halogen (WI) lamp (370700nm)

Diffraction Grating Blazed holographic type with 1200 grooves/mm

Cell volume (STD) 8µl (lmmØ X 10mm)

Cell pressure tolerance 30kg/cm 2

Materials in contact with liquid SUS 316, quartz, Teflon

Base line noise 3 X 10 -5 AU Max. at 250nm, 500nm

(using air in the cell, as a response STD)

Base line drift 1 X 10 -3 AU/hour Max. 250nm, 500nm

(using air in the sample cell)

Measurement range 0.001, 0.002, 0.005, 0.01, 0.02, 0.04, 0.08, 0.16, 0.32, 0.64, 1.28, 2.56, AUFS - intervals of selectable in 12-steps

Response 3-step selection: FAST, STD and SLOW

Corresponding to 0.05, 0.5 and 1.5 sec time constants. However, an internal switch can change the time constants to 0.1, 1.0 or 3 sec.

Zero adjustment Auto zero by pushbutton switch

Zero adjustment range Maximum of 1.4AU

Zero adjustment accuracy Maximum of ± 1 X 10 -4 AU

Recorder terminal outputs 1mV, 10mV full scale

Integrator terminal output 0.4V/AU, 0.8V/AU

Weight 14kg

Size 26(W) X 16(H) X 40(D) cm

Optimum operating temperature range 10° to 40°C

Power requirements (SPD-6AV is classified as follows according to supply voltage.)

P/N 228-15001-91 100V ± 10V 1.3A 50, 60Hz

P/N 228-15001-92 115V ± 10V 1.3A 50, 60Hz

P/N 228-15001-93 220V ± 20V 0.7A 50, 60Hz

P/N 228-15001-94 240V ± 20V 0.7A 50, 60Hz

P/N 228-15001-95 230V ± 20V 0.7A 50, 60Hz

Column Oven CTO-10A

The column oven is an air circulation type thermostatic chamber for the high performance liquid chromatograph system. the intention of the oven is to maintain the temperature of the columns and the flow lines constant for improving analysis repeatability and the separation function.

The high performance liquid chromatography system requires a liquid pump unit, injector, column, detector, system controller, etc. in addition to the thermostatic chamber. Since they are sold individually, consult the nearest our branch office, sales office, or agent on selecting appropriate components for the purpose of analysis intended.

This instruction manual is common to the CTO-10A controlling temperature only by a heater and the CTO-10AC capable of controlling temperature lower than the room temperature by a built-in cooler. Confirm the model number of your column oven before reading the manual.

The manual refers only to the handling of the CTO-10/AC, the options related to the CTO-10A/10AC and not of other components (extra options). Information on other components is given in the respective instruction manual.

Specifications

Method Forced air circulation method

Temperature control range CTO-10A : (Room temp. + 10 °C) to 80°C

Temperature setting 4 to 80°C in steps of 1°C range

Temperature control ±0.1°C accuracy

Operating surrounding 5 to 35°C temperature range

Internal dimensions of Width 220mm, depth 95 mm, height 365 mm

column chamber

Safety features a) Upper limit temperature is settable to prevent overheating. Provided with a built-in thermal fuse.

b) Provided with a built-in inflammable solvent leak sensor.

Air circulation fan Automatic adjustment according to the temperature setting speed adjustable given

Time program function Temperature setting change, temperature regulation start and stop 32 steps,1 to 999 minutes

Overall dimensions Width 260 mm, depth 420 mm, height 415 mm

Weight CTO-10A : 20 kg

Power supply

228-24000-91 AC100 ±10V 550VA

228-24000-92 AC115 ±10V 550VA

228-24000-93 AC220 ±20V 550VA

228-24000-95 AC230 ±20V 550VA

228-24000-94 AC240 ±20V 550VA

Chromatopac C-R7A

The C-R7A Chromatopac is a highly efficient and multi-functional data processor with a built-in thermal sensitive or injection type printer plotter, a floppy disk drive, a LCD and a full keyboard. The C-R7A is provided with many convenient functions. Some of the features are shown below.

Space saving compact design

The C-R7A consists simply of a lap-top type main unit and an external printer plotter. The sliding LCD can be used with its face up on the keyboard.

User-friendly operation

The menus are configured by 4 independent multi-windows. The unit features easy menu selection using the pop-up windows and Help function, thus providing easy selection of a menu. All the operations related to data processing can be done using the simple Operation keyboard. Therefore an operator who is not familiar with the full keyboard can use the unit easily.

High-quality reporting function

The thermal sensitive and injection selective printer/plotter is Optimum for printing the analysis report. By setting the report format, the analysis report format can be changed. Plotting of calibration curves is also available to report tl-ie cai ration.

Autocutter

By using the autocutter, the analysis report can be cut to A4 size or can be output as a continuous chart in unit of analysis report.

2-channel simultaneous processing

The unit is capable of two-channel processing which processes data for two channels simultaneously, when 2 cannel board (the optional accessories) are mounted.

Re-analysis of data

The data analyzed once can be re-calculated due to identification deviation or re-analyzed by changing the peak processing parameters, or using visual specifying a peak processing method directly while observing the data on the LCD.

Monitoring of GC statuses and analytical conditions

The GC statuses can be monitored from the C-R7A unit, and further the analysis conditions can be set from the unit, as well.

Laboratory Automation(LA)

The newly added preatretment program makes it easy to control external devices. It provides a powerful support of analysis together with a Chromatopac BASIC.

The Standard RS-232C highly-functional serial communication provides availability to be used with a large-scale system.