Rheodyne Ventil 7725 i

| Objektnummer | B00013504 |

|---|---|

| ID-number | 013504 |

| Object name | Rheodyne Ventil 7725 i |

| Status | Stock unit |

Product group: HPLC-Miscellaneous

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

Models 7725/7725i and 9725/9725i

Sample Injectors for HPLC

Figure 1. Rheodyne 7725/7725i stainless steel (left) and 9725/97251 PEEK (right) front Iosding sample injection valves for HPLC

Rheodyne 7725/7725i and 9725/ 9725i front loading HPLC Sample Injectors are easy to use, and provide chromatographers with the Rheodyne Hallmark of Excellence... unparalleled performance and exceptional product lifetime.

Patented Make-Before-Break (MBB TM ) architecture virtually eliminates transient pressure shocks for extended column life

Available in stainless steel and PEEK for sample compatibility

Zero sample Ioss

2 µL internal sample loop accessory available

Wide 30° port angles for easy access

Position sensing switch built into "i" models

Small diameter internal flow paths assure minimal dispersion

MBB Flow Design for Pressure Shock Reduction

Rheodyne's exclusive MBB flow architecture virtually eliminates pressure transients. The high pressure flow from the pump is uninterrupted when the injector is switched between LOAD and INJECT, a benefit when using flow sensitive detectors, fragile columns, or pumps that are disturbed by flow or pressure transients.

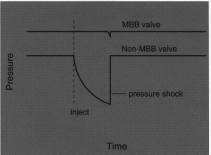

Fig.2 shows column pressure vs. time for MBB (upper curve) in comparison to non-MBB sample injectors (lower curve).

Fig. 2 shows column pressure vs. time for MBB (upper curve) in comparison to non-MBB sample injectors (lower curve).

A passage in the stator face assembly makes new connections before old ones break. This patented Make-Before-Break (MBB) design is an improvement over injectors which use a bypass. lt is easy to troubleshoot, and does not dilute sample.

.

Mechanical Design

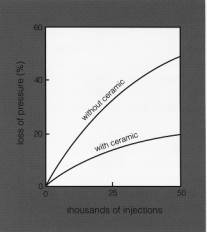

The Interface between the rotor and stator face is the location of the flow switching and high-pressure sealing. This Interface is a flat surface, and consists of a rotor seal made of an inert polymer, and a ceramic stator face assembly. The highly-polished ceramic does not scratch or wear under normal use.

As a result, a rotor seal should last for tens of thousands of injections in normal use, and shed very few particles

Figure 3. Pressure loss of stainless steel/polymer valve (top) and Rheodyne ceramic/polymer valve (bottom) vs. thousands of injections.

Position Sensing "i" Injectors

In the 7725i and 9725i valves, turning the valve to INJECT closes a built-in position sensing switch, which remains closed until the valve is returned to LOAD. When the position sensing switch wires are attached to a chromatograph, the switch provides the System with a reproducible start signal.

Zero Sample Waste

A syringe needle with a flat end (square cut) must be used. When the needle is inserted into the needle port, the tip of the needle passes through a seal inside the rotor seal, and then contacts the ceramic stator face. This direct connection between the tip of the needle and the end of the loop eliminates sample holdup. All sample leaving the needle enters the loop, so there is zero sample waste.

Leak Tight Needle Seal

The needle seal is a Teflon sleeve that is built into the rotor seal. lt grasps the tip of the needle, aligning it with the loop passage, and assures that all sample dispensed from the syringe enters the loop. The seal is under compression from an internal spring, which maintains a leak-tight, self-adjusting seal around the needle.

Sample Injection

The needle port of each injector is built into the valve's handle. When the injector is mounted an a panel, the handle and needle port are in front (Fig. 4A). In back of the panel are the body and the stator. The stator contains six tubing ports (Fig. 4B) for connecting the pump, column, sample loop, and vent lines.

Fig. 4A shows a cut-away view of the valve in both the LOAD and INJECT positions. Below the cut-away view is an illustration of the internal flow passages. The six circles represent the ports in the stator. The arcs represent the connecting passages in the rotor. The needle port is shown aligned with port 4.

In the LOAD position mobile phase flows to the column via port 2, a rotor passage, and port 3. The loop, which contains mobile phase trapped when the injector was returned to LOAD, can be partially or

completely filled with sample from a syringe via the needle port, which aligns with port 4. The mobile phase displaced by the sample exits the loop via drain at port 6.

With the syringe still in the needle port the valve is turned to clockwise through 60 ° to INJECT. Channels in the rotor seal now directthe mobile phase intotheend opposite from where the sample entered the loop. Note that the sample travels in a direction opposite to the direction during loading; it does not have to pass through the entire loop. The needle port and syringe now align with drain at port 5. When the needle port is flushed, the flushing solvent exits directly out this port without entering the sample loop. The needle port and syringe are never exposed to high pressure. The loop is self-cleaning, being continuously flushed by mobile phase during analysis.

VERSATILE INJECTION METHODS

Rheodyne front loading injection valves operate as follows: Sample is first LOADED into the sample loop by dispensing it from a syringe (Fig. 5) or by pulling it through a dip tube using a Suction Needle Adapter (Fig. 6). Sample is then INJECTED onto the column by turning the handle, which connects the loop to the high-pressure mobile phase stream. These versatile injectors offer a choice of three loading methods: Complete, Partial, and Suction.

Sample Injection using

Complete Filling Method

When injection volumes do not often change, or when sample conservation is not required, complete filling is the method of choice. The complete fill method produces excellent volumetric precision, typically about 0.1% relative standard deviation. Sample is dispensed from a syringe, using an excess amount

(at least 3 times the loop volume) to displace all the mobile phase in the loop. The loop sets the volume injected; the volume is varied by changing the loop size. Since the loop sets the volume, this method does not require precise use of the syringe.

Sample Injection using

Partial Filling Method

Applications where injection volumes change frequently, or when sample conservation is important, partial filling is the method of choice. Volumetric accuracy and precision depend an the operator's ability to read and use the syringe, typically about 1%. The volume injected is determined by the amount dispensed into the loop by the syringe. The amount dispensed must be less than half of the total loop volume. The partial fill method does not waste sample, and allows the volume to be continuously varied without changing the loop.

In partial filling (load no more than 50% of the loop volume), all of the sample dispensed from the syringe needle enters the loop, even with samples as small as 0.1 uL. There is zero sample waste.

Sample Injection using

Suction Method

Rheodyne 9725 (PEEK) valves have no metal in contact with the flow stream. The preceeding methods expose sample to the metal needle of the syringe. Though the exposure is small, metal can be completely avoided by using a syringe to suck sample into the loop via a PEEK tube at port 6. Using this method the tube end is placed into the sample vial. An empty syringe is inserted into the needle port, and used to pull sample into the loop. Model 9125-076 Suction Needle Adapter, an accessory listed under ordering information, is recommended forthe suction method. As shown in Fig. 6, the adapter makes suction loading easier.

SPECIFICATIONS

Stainless Steel Model: 7725 and 7725i

Maximum Pressure: 48 MPa (482 bar, 7000 psi)

Wetted Surfaces: 316 stainless steel, alumina ceramic, and an inert polymer

pH Range: 0-10 (pH >10, contact factory)

Maximum Temperature: 80°C

Flow Passage

Diameters: 0.6 mm (0.024") and 0.5 mm (0.018")