Photometrics CH 250

| Objektnummer | B00009925 |

|---|---|

| ID-number | 009925 |

| Object name | Photometrics CH 250 |

| Status | Stock unit |

Product group: Life science / Biotechnology

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

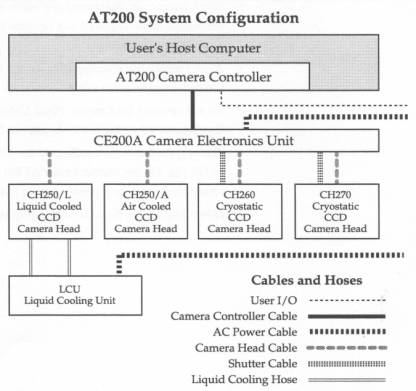

The AT200 CCD Camera System brings the capabilities of Photometrics" Series 200 charge-coupled device (CCD) camera hardware to host computers that are based on the AT ® bus architecture. The AT200 system hardware has been designed to integrate easily with your host computer.

Photometrics offers a variety of application and development software packages for the AT200 system. Your choice is governed by the type of work you need to do. Each software package includes an installation manual.

The AT200 CCD Camera System consists of three hardware components:

AT200 Camera Controller

CE200A Camera Electronics Unit

CCD Camera Head (models CH250/L, CH250/A, CH260, or CH270)

A system with a CH250/L liquid-cooled CCD Camera Head also requires a liquid cooling unit (LCU), such as the Photometrics LCU.

AT200 Camera Controller

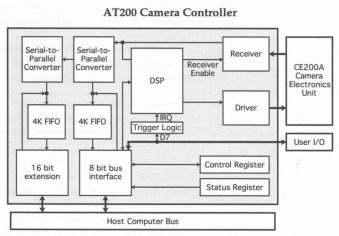

The AT200 Camera Controller manages communications between a host computer that is based on the IBM ® PC/AT bus architecture and a CE200A Camera Electronics Unit.

A digital signal processor (DSP) sends control signals to the CE200A via the Camera Controller Cable; CCD data are received through the same cable. The AT200 has no memory of its own, so incoming data must be promptly stored in host RAM. Once collected into host memory, the data can be manipulated by software on the host computer.

The AT200 occupies 16 contiguous I/O address locations on the AT bus. The controller's auto-addressing logic allows host software to locate the AT200 at a blank I/O address. This ensures that the board address block does not contend with any other card in the host system.

The AT200 can be synchronized to external equipment or to a manual trigger with the User I/O connector. The connector, located next to the DB25 connector on the back of the AT200. The manual for your Photometrics application or development package provides information on implementing User I/O functions.

CE200A Camera Electronics Unit

The CE200A Camera Electronics Unit contains signal processing, camera control, and temperature control systems. It produces CCD clocking signals for the CCD Camera Head and manages the transfer of raw CCD data to the AT200.

The CE200A Camera Electronics Unit contains signal processing, camera control, and temperature control systems. lt produces CCD clocking signals for the camera head and manages the transfer of raw CCD data to the camera controller.

The internal components of the CE200A include a triple-voltage power supply, a temperature controller, an electronics card Gage, and a fan. A CE200A used with a thermoelectrically cooled camera head also contains a power supply for the thermoelectric cooler.

CCD Camera Heads

Photometrics CCD Camera Heads are cooled to reduce dark current, the spontaneous charge generated by heat and other non-photon sources. Cooling is achieved by two methods: thermoelectric (Peltier) cooling and cryostatic cooling. The CCD is housed in a vacuum chamber to improve cooling efficiency.

Each CCD Camera Head is composed of a sealed CCD enclosure, a shutter assembly, and a lens. The head contains electronics that are directly associated with CCD operation. The Camera Head Cable transmits voltages and signals to and from the CE200A. A preamplifier raises the CCD output signal to a high level for digitization.

The lens for your CCD Camera Head has a standard 35mm bayonet mount. To attach the lens, insert it into the lens mount and turn it counterclockwise until it seats.

The CCD Camera Head can also be affixed directly to an instrument. Photometrics offers CH250/L and CH250/A CCD Camera Heads with thermoelectric cooling, and CH260 and CH270 CCD Camera Heads with cryostatic cooling.

Photometrics CCD Camera Heads are cooled to reduce dark current, the spontaneous charge generated by heat and other non-photon sources. Cooling is achieved by two methods: thermoelectric (Peltier) and cryogenic (liquid nitrogen) cooling.

Photometrics offers the CH250/L or CH250/A CCD Thermoelectric Camera Head and the CH260 or CH270 CCD Cryostatic Camera Head. Each camera head is composed of a sealed CCD enclosure, a shutter assembly, and a lens. The CCD Camera Head contains electronics that are directly associated with CCD operation. The standard lens is a Nikon 35mm bayonet mount. You can affix the camera head directly to an instrument.

The sections that follow give an overview of each CCD Camera Head. They include specifications, operational requirements, and storage requirements.

CH250/L CCD Camera Head

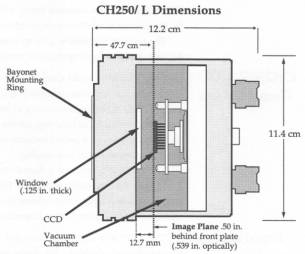

The CH250/L Liquid Cooled CCD Camera Head is composed of a sealed CCD enclosure, a shutter assembly, and a lens.

The CCD enclosure is made up of four major components-a back heat sink assembly, a cylindrical housing, a front plate, and a window assembly joined with a vacuum seal. A sealed vacuum valve is provided in the event the camera head requires repair or re-pumping.

Specifications

Weight, excluding lens: 2.5lb (1.1 kg)

Length, excluding lens and excluding connector: 4.8 in (12.2 cm)

Diameter: 4.5 in (11.4 cm)

Distance from front of vacuum chamber to CCD image plane: .50 in (12.7 mm)

Distance to front of bayonet mounting ring from CCD image plane: 1.88 in (47.7 mm)

Suggested coolant: 50% ethylene glycol and 50% deionized water

Minimum coolant flow: 6 gallons per hour (23 liters per hour)

CCD operating temperature: Dependent on CCD. For details, refer to camera head specification sheet.

The length, diameter, and distances are shown in the figure CH250/L Dimensions.

Operational Requirements

Ambient Temperature: from 0°C to 40°C

Relative Humidity: from 0% to 80%, non-condensing

Storage Environmental Requirements

Ambient Temperature: from -20°C to 50°C

Relative Humidity: from 0% to 90%, non-condensing

CCD Camera Implementations

To take advantage of the high performance a CCD has to offer, special slow scan or still-imaging cameras have been designed to operate at a significantly lower speed than conventional video cameras. These cameras bring together several diverse technologies: high-performance signal processors, solid-state coolers, precision digitizers, and high-speed digital controllers. The benefits of slow scan readout are ultra-low noise, maximum CCD performance, and photometric precision in the image data.

A precision analog processing circuit and analog-to-digital converter are employed to amplify and digitize the CCD output signal. CCD readout may take from one tenth of a second up to several seconds, as each pixel is digitized with up to 16-bit precision. The digitized electronic image read out from the CCD can be stored in a computer's memory. Slow scan camera systems produce large quantities of data. A 2000 x 2000 pixel CCD with a dynamic range of 20,000:1 requires eight megabytes of storage for each image.

Cooling the CCD reduces dark current to negligible levels, allowing exposure times of up to hours in duration. To achieve the highest possible sensitivity, astronomers cool the CCD with liquid nitrogen, eliminating the dark current produced by thermal generation at warmer temperatures.

High energy physicists, on the other hand, use CCDs in ultra-high speed cameras to observe transient phenomena where dark current is not relevant.

A conventional shutter can be used to acquire exposures as brief as a few milliseconds or as long as an hour; a microchannel plate image intensifier can be used to gate exposures of a few nanoseconds.

Resolution

The resolution of a CCD camera is determined by the geometry of the specific CCD in use. The CCD pixels set the limit of resolution. In scientific-grade CCDs, a pixel varies in size from a few micrometers up to 48 µm; the total imaging area is 1 to 24 cm 2 . In order to avoid aliasing, moiré, or beat frequencies, the magnification must be chosen so that at least two CCD pixels cover a desired resolution element in the image plane.

There is no dead space between pixels. Charge generated by photons striking the CCD between pixels diffuses to the nearest potential well. This is referred to as "fill factor."

Sensitivity

The sensitivity of a CCD imager to light is determined by system noise level and quantum efficiency.

Quantum efficiency measures the sensor's efficiency in generating electronic charge from incident photons. Electron hole pairs are produced by photons in the region from 400 to 1100 nm. Within the visible spectrum, the photon to electron conversion factor is less than unity and it varies as a function of wavelength. At a given wavelength, the creation of charge from incident light is intrinsically linear.

Spectral Response

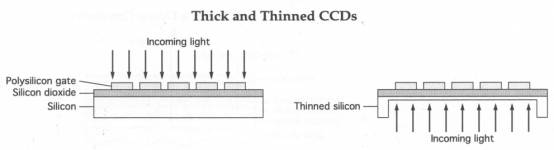

Light normally enters the CCD through the gates of the parallel register. These gates are made of very thin polysilicon which is reasonably transparent at long wavelengths but becomes opaque at wavelengths shorter than 400 nm. Thus, at short wavelengths the gate structure attenuates incoming light.

Thinning

With acid etching techniques, CCDs can be uniformly thinned to approximately 10 µm, and an image can be focused on the backside of the parallel register where there is no gate structure. These thinned, or backside-illuminated, CCDs exhibit high sensitivity to photons from the soft X ray to the near-infrared regions of the spectrum. Thick and Thinned CCDs illustrates the structures of both kinds of device.