Heraeus M 104

| Objektnummer | B00013490 |

|---|---|

| ID-number | 013490 |

| Object name | Heraeus M 104 |

| Status | Stock unit |

Product group: Ovens

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

The following illustrations and descriptions are referring to the instrument model and are drawn from brochures. They are not representing the delivery volume. The exact delivery content you will find only in the offering text.

AREAS OF APPLICATION

The muffle/chamber furnace is designed for thermal technology applications in the laboratory:

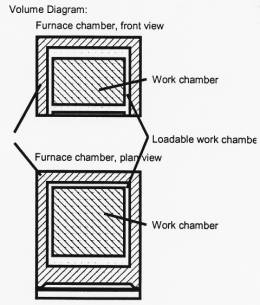

Volume of furnace work chamber 4.7 1 (M 104) or 3.8 1 (K 114)

Heat treatment of samples and objects from 300 °C to 1000 °C (M 104) or to 1100 °C (K 114)

Loads of up to 5 kg

The unit is generally designed for installation and operation in the following areas:

Laboratories, such as those found in manufacturing trades and industry, schools, universities, hospitals and biology.

lt is used for:

ageing, analysis, tempering, decomposing, baking, annealing, hardening, soldering, oxidising, reducing, incineration and preheating.

The over-temperature protection "upper limit cut-out" which can be supplied with the unit enables operation without constant supervision.

The unit is designed for continuous operation.

To avoid samples being unevenly exposed to heat, care must be taken to maintain a distance from the inner surfaces of the furnace work chamber.

Provisions should always be made to provide operators with protective clothing, such as working gloves and protective glasses, due to the often high temperatures existing in the working environment.

Do not use the unit:

- to heat up foods

- for drying or heat treatment of substances which release gases or vapours Into the atmosphere that are flammable or dangerously explosive when mixed with air. This furnace is equally unsuitable for the heat treatment of combustible dusts and fibrous materials.

DESCRIPTION OF UNIT

The basic design of the unit comprises casing, work chamber, tilting door and switching and controlling components.

The work chamber of the M104 laboratory muffle furnace consists of a ceramic muffle. The heating elements are covered and embedded in the muffle. The muffle furnace is designed to operate at temperatures of up to 1000 °C.

The work chamber of the K 114 laboratory muffle furnace consists of fiberboard. Exposed heating elements are set into grooves in the walls and ceiling of the furnace chamber. A ceramic plate covers the floor of the furnace chamber. The unit is designed to work at operating temperatures of up to 1100°C.

Fiber materials provide the unit with thermal insulation showing reliably good heat containment properties and temperature/time parameters.

The metal surfaces around the mouth of the furnace can become extremely hot during Operation at high temperatures. Care must be taken against the danger of injury. To warn against touching them, these surfaces have accordingly been marked with the Symbol shown here.

The furnace chamber is closed off by a tilting door.

The door is opened and closed with a lever on the right side of the unit. The hot interior side of the door swings downward when the door is opened. An integrated protective shield against escaping heat and heated particles simultaneously folds out. The lowered door then serves as a surface on which the unloaded samples can be placed.

There is an aperture (Ø 5 mm) in the middle of the swing door which serves as an access for encased thermocouples providing external measurement of temperatures inside the furnace chamber.

Special measures must be taken and strictly observed to ensure protection of persons from electrical shock when using external temperature measurement devices. Failure to observe these measures is EXTREMELY HAZARDOUS and presents a DANGER of DAMAGE TO ALL CONNECTED SYSTEMS - please refer to instructions in the appropriate section of this manual.

The operating elements for built-in electrical components are integrated into the operating panel of the switching and control unit.

The unit is designed as a plug-in unit and is supplied with a fixed mains connection. A PE conductor (protection class 1) provides protection against electrical shock.

The laboratory furnace is equipped with radio interference suppression.

Temperature control is provided by an electronic temperature controller featuring a sensor defect indicator. The interior temperature is measured by a thermocouple. A power semiconductor in the temperature controller regulates the power supplied for heating.

SAFETY STANDARDS

The unit meets the following safety standards:

DIN 12 880 Section 1 / 11.78

DIN VDE 0700 Section 1 / 04.88

DIN VDE 0875 Section 11 / 07.92

The M 104 / K 114 laboratory muffle and chamber furnaces have also been safety-tested by the testing and certification institute VDE. Certain models (see APPENDIX) comply with GS certification standards and with interference standards, depending the optional equipment installed.

TECHNICAL SPECIFICATIONS

MECHANICAL

Dimensions (w x H x D)

Outer dimensions: 456 x 646 x 570 mm

Furnace chamber

(excl. door insulation): 170 x 130 x 215 mm

Loading space in furnace chamber: 130 x 110 x 205 mm

Usable space (DIN 17 052 Class C,

heated depth 160 mm): 130 x 80 x 120 mm

Base plate (w x H x D): 145 x 10 x 240 mm

Min. distance of the furnace to neighboring surfaces

left: 25 mm

right: 100 mm

top: 300 mm

at rear (with spacer): 80 mm

at rear (with exhaust flue): 100 mm

at rear (with exhaust fan):

190 mm

Volumes

Furnace chamber: 4,7 l

Loading space in furnace chamber: 2,9 l

Usable space (DIN 17 052 Class C, heated depth 160 mm): 1,2 l

Weight

Unit: ca. 52 kg

Maximum load:

5 kg

THERMAL:

Operating temperatures: 300 ... 1000 °C

Temperature deviation

Temporal (DIN 12 880 Section 2)

with spacer: < ± 1 K

with exhaust flue: < ± 1 K

with exhaust fan: < ± 2 K

Spatial (DIN 17 052 Class C)

at 500 °C: ± 12,5 K

800 °C: ± 7,0 K

1000/1100 °C:

± 7,5 K

Heat rise time (without load)

with spacer / exhaust flue

to 500 °C: ca. 80 min

to 800 °C: ca. 90 min

to 1000/1100 °C: ca. 120 min

with exhaust fan

to 500 °C: ca. 50 min

to 800 °C: ca. 85 min

to 1000 °C:

ca. 160 min

Cool down time (to 100 °C, without load)

with spacer / exhaust flue

from 500° C: ca. 540 min

from 800 °C: ca. 670 min

from 1000/1100 °C: ca. 730 min

Without exhaust fan

from 500 °C: ca. 255 min

from 800 °C: ca. 325 min

from 1000 °C:

ca. 350 min

Heat radiation to surrounding areas

at 500 °C: 0,4 kW

at 800 °C: 0,8 kW

at 1000/1100 °C: 1,1 kW

VENTILATION / FLUE GASES:

Air replacement in furnace chamber

without / with exhaust flue

at 500 °C: ca. 15 h -1

at 800 °C: ca. 10 h -1

at 1000/1100 °C: ca. 8 h -1

with exhaust fan

at 500 °C: ca. 500 h -1

at 800 °C: ca. 345 h -1

at 1000 °C: ca. 340 h -1

Flue gas flow (without ioad) without/ with exhaust flue

at 500 °C: 70 l/h

at 800 °C: 47 l/h

at 1000/1100 °C: 38 l/h

with exhaust fan 46 m 3 /h

Diameter of duct - flue / exhaust fan: 35 / 52 mm

Flue gas temperature at duct

(at max. operating temp.) 80 (330 1) ) °C

without / with exhaust flue:

with exhaust fan: 110 (200 1) ) °C

1) the higher value applies momentarily an closing of door

NOISE:

Noise level (DIN 45 635): < 58

ELECTRICAL:

± Rated voltage (10%): 1/PE AC, 230 V

Rated frequency: 50/60 Hz

Nominal power consumption: 2,5 kW

Connected ioad: 2,6 kVA

Current ioad: 11,4 A

Protection class: 1

Protection type: IP 20

Circuit protection:

(Electrotechnical regulations and EVU-specific technical requirements are to be observed when connecting to mains power supply circuits).

T 16 A fuse or B 16, circuit breaker, connection to leakage current protection switch ( ≤ 30 mA) recommended.

MATERIALS USED

Outer casing Zinc-plated sheet steel, painted RAL 9002

Furnace chamber Ceramic C 530, DIN VDE 0335

Door insulation Fireclay brick (chamotte)

Mouth of furnace Fireclay brick (chamotte)

Thermal insulation of the

furnace chamber Aluminum silicate fiber 1)

Base plate Fireclay brick (chamotte)

Tray Heat-resistant steel

Heat coils Cr Al Fe

Control panel Mixture of ABS and PC

Electrical components Components coated with various

plastics, partially mounted with epoxy resins an circuit boards strengthened with glass fiber.

1) Fiber materials used for insulation are classified as hazardous to health in certain countries. No serious risks to the working environment arises from normal Operation. Improper handling during repairs or dismantlement of the unit can lead to significant levels of contamination.