Anton Paar Multiwave

| Objektnummer | B00019172 |

|---|---|

| ID-number | 019172 |

| Object name | Anton Paar Multiwave |

| Status | Stock unit |

Product group: Digestion systems

Status, terms of delivery and payment

Verification of devices

The second-hand devices are verified by Labexchange Service GmbH before delivery. You are receiving only fully functional devices.

Dispatch time

The stated dispatch times are the shortest possible ones for each article. The effective dispatch times can vary. The effective dispatch times will be stated in the order confirmation.

As a matter of principle, we are offering collective deliveries. The shipping time is calculated based on the position with the longest lead time. A partial delivery is possible on explicit request.

Shipping methods

Parcel services, forwarding agencies, self-pickup, delivery by Labexchange fleet.

Delivery information

Prices exclude shipping costs. Stated shipping costs are to be expected. Deviations are possible. If transport costs are not specified, please ask separately for them.

The stated transport and packing charges apply to the most favorable route if transport and are to be understood as subject to verification due to unexpected cost increases. By reason of unpredictable events, cargo rates and delivery times can change at any time and therefore have to be adapted to the recent situation. Import formalities and possible customs charges will be borne by the purchaser. Incoterm coding according to Incoterms 2010: For persons who collect the devices themselves: EXW, for dipatch by sea: CFR, by air freight: CPT, other shipments: DAP. Note for international shipments: A proof of preference/EUR1 will not be issued by us. When self-collecting/ordering EXW from countries within or outside the European Union, 16% VAT will be retained as a deposit until we have received the corresponding confirmation of arrival/bill of delivery from the buyer.

Terms of payment

We do not accept payment by letter of credit, PayPal, etc. In each case the invoice amount is payable without deduction. Discount is not granted.

|

Country |

Possible payment methods |

Comment |

|

DE, AT, CH |

Payment by invoice, payment in advance, paymet by credit card |

Payment by invoice is only possible for corporate clients. |

|

NL, BE, LU |

Payment by invoice, payment in advance, payment by credit card |

Payment by invoice is only possible for corporate clients |

|

Other countries |

Payment in advance, payment by credit card |

|

Our General Terms of Sale, Delivery and Payment are valid and are available for download here.

The goods are offered subject to prior sale.

Definition of status

All articles are used articles, except an article is listed especially as a new device.

|

Status |

Condition |

Comment |

|

Immediately available |

Used | The article is fully functional and in impeccable condition. It can be shipped immediately. |

| In stock |

Used |

The article is on stock. Our service technicians will verify the article before delivery. You are receiving only a fully functional article. |

|

Published |

Used |

The article is still with the provider. After your order the article will be purchased and verified by us before being shipped to you. A certificate of operativeness as well as a service report are included in delivery. |

|

New device |

new |

The article is brand new and unused. Regarding new equipment the guarantee/warranty conditions of the corresponding manufacturer apply. |

|

Labprocure |

Used |

Labprocure GmbH, as the advertiser, is responsible for the content of this device offer. Labprocure assumes liability for the offers advertised here and for the photos and offer texts included. Labprocure GmbH, Bruckstraße 58, 72393 Burladingen. |

manufacturer: Paar

model: Multiwave

annotation: Dokumente engl.

The following illustrations and descriptions refer to the instrument model and are drawn from brochures. They do not represent the scope of delivery. Please refer to the text of the offer for the exact scope of delivery.

Features

Unique vessel cooling system

Cooling time is no longer a limiting factor! MULTIWAVs built-in forced-air cooling system prevents overheating and cools vessels in minutes after the end of a decomposition. Special air gap design and the use of quartz and ceramics provide efficient hegt transfer.

Drastically reduced cycle time

No external cooling required

No handling of hot pressure vessels

IR temperature Sensor

Temperature curves of each sample are displayed by the integrated Computer. An infrared sensor measures the temperature at the bottom of each vessel through ports in the rotor base.

Temperature controlled and documented process

Protection against overheating

Remote sensing - no installation, no contamination

Double safety door

Maximum safety is a major benefit of the MULTIWAVE system. Users are

efficiently protected in case of spontaneous reactions. The extensive safety measures are completed by a shield an the oven door, which remains locked when the inner door opens for safe and controlled release of overpressure.

Multiple door interlocks

Easy one-latch operation

PTFE-coated cavity

Durable, industrial-quality components make the MULTIWAVE suitable for harsh laboratory conditions. Its stainless steel cavity is completely protected by a multi-layer PTFE coating.

Maximum corrosion resistance

Easy cleaning and maintenance

Unpulsed microwave power

Precise regu!ation of energy is particularly important for sensitive reaction control. MULTIWAVE delivers unpulsed microwave power over its full 1000 W Tange, controlled by reaction Pressure or temperature.

Fast and efficient heating

Increased service life of magnetron

Built-in industrial-type PC

On-line documentation and control of process parameters is available at the push of a button. MULTIWAVE has its own built-in computer and provides

you with intelligent and comfortable software solutions. lt contains comprehensive sample and methods libraries including standardized EPA-procedures (3015, 3051, 3052). Use them as they are or customize them to create your own methods.

Built-in "digestion experience"

Software safeguards

Bright graphic display

Output to printer or PC

Serial RS232 and parallel Printer interface is standard for every MULTIWAVE.system. For GLP-compliant documentation simply connect a printer or transfer data to an external host PC.

Magnetic stirrer (option)

Reaction rates and recoveries can be further enhanced with a magnetic stirrer. MULTIWAVE provides this option to intensify contact of sample and reagents in vessels H F50 and MF100.

Gas/vacuum connections (option)

For inert gas purging or evaporation applications optional ports are available for the connection of scrubbers, etc

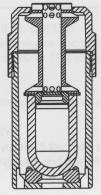

High Performance Reaction Vessel System

Reaction vessel performance is the basis for decomposition quality. The Anton Paar MULTIWAVE system offers a well balanced choice of vessels and rotors with exceptional modularity and interchangeability. This flexibility allows you to select optimized systems for a wide variety of organic and inorganic matrices. The use of advanced materials provides the outstanding vessel specifications.

All MULTIWAVE vessels are designed for safe, convenient handling. Unique, patented features like self-sealing lip-type seals, air cooling and remote sensing systems reduce working steps and errors and increase the productivity of your analytical lab.

- Superior digestion quality eliminates chemical interference during the analysis

- Hermetic seal avoids losses or contaminations

- Short cool-down timen provide high sample throughput

- Compound designs Show unmatched dimensional stability and Service life

- No pressure derating at max. temperature!

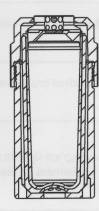

12 position Rotor 12LF100

For samples that decompose at moderate temperature and pressure the Rotor 12LF100 is the maximum productivity workhorse. 100 mL reaction vessels with high overpressure tolerante make decompositions safe and efficient. A reference pressure sensor vessel is used to control the process. Up to nix vessels can be temperature controlled. The integrated air cooling system reduces sample turn-around time and material stress.

Installation-free sensor technology

Easy handling of seals and vessels

High safety level

6 position Rotor system

Ultimate flexibility, performance and reaction control is characteristic for the 6-position rotor system:

Continuous temperature and pressure control in every vessel

Four different typen of heavy duty vessels fit into the saure rotor

Multiple safety devices

Work with MULTIWAVE to convince yourself how easy it is to use! Handtightening of vessels and rotor make setup quick and simple. No sensor connections or other tedious Installation steps are required. Maximum compatibility of components allows you to change simply from one vessel type to another with automatic cut-off pressure matching.

Most advanced pressure sensor technology

Decomposition is now safe and easy, even for inhomogeneous samples or partially loaded rotors, with MULTIWAVE's unique pressure sensing system. lt simultaneously measures the pressure in all vessels of the 6-position rotor, always using the highest level in any of the vessels for accurate reaction control. Designed as a closed load cell, the sensor neuer contacts the sample. The remote sensing system doesn't require any honen, water fillings, not even electrical connections. Just innert the rotor into the cavity and the pressure sensor is ready to work.

Simultaneous pressure control of all vessels

No Installation, no tools required

No sample contamination

Reaction Vessel Specifications

HQ20

Small-volume high-temperature quartz vessel for analysis of microsamples for trace- and ultratrace analysis

HQ50

Heavy-duty hightemperature quartz vessel for trace- and ultratrace analysis of organic samples

HF50

TFM fluoroplastic vessel for high pressure reactions of materials which are incompatible with quartz

MF100

Large, general purpose TFM fluoroplastic vessel for versatile applications

LF100

PFA fluoroplastic vessel for 12-pos. rotor, gives high throughput with moderate pressure samples

HQ20 HQ50 HF50 MF100 LF100

Volume 20 mL 50 mL 50 mL 100 mL 100 mL

Reaction Vessel Quartz Quartz TFM TFM (PFA) PFA

Supporting vessel - - Ceramics Ceramics Ceramics

Op. Pressure 75 bar(1100 psi) 75 bar(1100 psi) 75 bar(1100 psi) 30 bar (440 psi) 20 bar(300 psi)

Max. Pressure 130 bar(1900 psi) 130 bar(1900 psi) 130 bar(1900 psi) 70 bar (1030 psi) 70 ba (1030 psi)

Max. Temperature 300 °C 300 °C 260 °C 260 °C 230 °C

Applicable rotor type 6-position 6-position 6-position 6-position 12-position

Typ. Sample Weight 10 - 200 mg 100 - 1000 mg 50 - 500 mg 100 - 1500 mg 100 - 1000 mg

Max. Filling Volume 6 mL 20 mL 20 mL 50 mL 50 mL

Typical Applications

Biochemicals

Pharmaceuticals, bi ological & forensic microsamples

Food (high fat)

Plastics, fibers

Oil, grease, coal

Pigments

Semiconductor

Ceramics

Oxides

Ashes, Blags

Soil, sediments

Geological material

Metals, ores

Glass, quartz

Water, effluents

Seesage sludge

Beverages

Plant material

Metals, alloys

Specifications

System design

Platform System with integrated solutions for high performance sample digestion, leaching, drying and evaporation under Full parameter control.

Microwave power

1000 W, wich unpulsed power control in 1 W increments.

Rotor Systems

Rotor 6HQ50, 61-1F50, 6MF100:

6-position high performance decomposition rotors with different typen of quartz or TFM vessels.

Rotor 12 LF 100:

12-position high sample throughput rotor.

Drying Rotor 1 DRY:

Drying chamber, volume 6 liter; with air inlet Filters. Slightly self-heating walls and bottom to avoid moisture condensation.

Evaporation Rotor 6EVAP:

For simultaneous treatment of 6 vessels (HF50, MF100 or LF100). Evaporation with filtered air or inert gas. Plug-in connection of vessels. Requires rotarg double lead through installed in oven cavity.

Pressure sensor

Simultaneous pressure control in all vessels of 6-position rotors, reference vessel for 12-position rotor.

Remote control, load-cell Sensors eliminate contact with sample solutions.

Temperature sensor

Infrared sensor for continuous control up to 300 °C.

Vessel cooling

Integrated, four stage high power exhaust unit, max. 100 m 3 /h.

Oven cavity

Stainless steel, coated with multilayer fluoroplastic.

Interface

Serial RS 232 C, parallel and keyboard.

Options

Magnetic stirrer

Rotarg double lead through (for gas inlet/outlet) Data transfer Software for external PC

Power supply

230 V AC, 50 Hz, 3300 VA or 230 V AC, 60 Hz, 3450 VA

Dimensions

64 cm wide x 67 cm deep x 49 cm high

Mass

45 kg